Home › Forum › Ask A Member › ’57 Evinrude 7.5 fleetwin fuel mix

- This topic has 33 replies, 15 voices, and was last updated 5 years, 4 months ago by

oldemtr.

oldemtr.

-

AuthorPosts

-

February 7, 2020 at 7:47 pm #194229

I mix 20 to 1 using today’s TCW3 oil in all 16 to 1 and 24 to 1 motors. Yeah, I know I should use a bit more in the 16 to 1 motors, but it’s a convenience thing; mixing a quart of oil to 5 gallons of gas (20 to 1), and not having to keep both 16 to 1 and 24 to 1 cans of gas around…….but……I don’t have a 16 to 1 motor that I run very often, so only running a gallon or so a year, the motors aren’t going to wear out any time soon. If I used one of these motors a lot, including my 7-1/2s, I’d go with 16 to 1. I also use 50 to 1 in 50 to 1 motors, and 50 to 1 in 100 to 1 motors. Some of the early 100 to 1 motors led short lives. When I put a motor on my grandson’s hydroplane (anywhere form 6 to 15 HP), I double the oil because these motors rev to RPMs they weren’t designed to run at. On the hydroplane I sometimes have to go one heat range colder on the spark plugs too.

Nobody ever killed a motor by using too much oil, and I’m amazed that my PO-15 Johnson at it’s recommended 8 to 1 doesn’t smoke a lot. Racing versions of the Champion “Hotrod” motors use 4 to 1.

Dave

February 8, 2020 at 5:52 am #194255Just speculation, but the 7 1/2 was the highest hp motor that had plain bearings so I wonder if they were concerned about bearing load(?)

-

This reply was modified 5 years, 5 months ago by

Steve Martin.

I like this theory. I do know from what I have seen, nothing will throw a rod faster than an AD on a lean oil mix.

Long live American manufacturing!

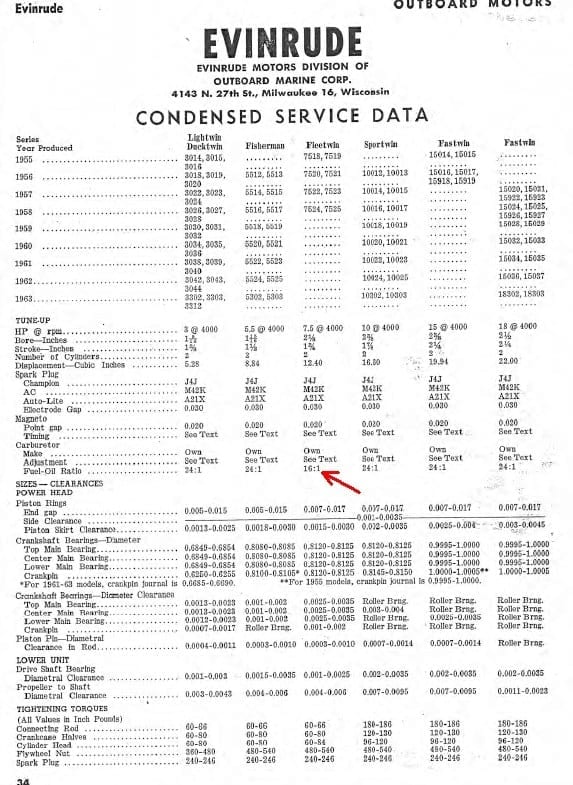

February 8, 2020 at 6:33 am #194256After taking a look at the chart that oldemtr provided, a few things became apparent.

This chart is from 1963 or later. The OMC 7.5 Hp had stopped production in 1958. The other models continued to be produced through 1963, and improvements were being made. Taking a look at the section titled “Crankshaft Bearings – Diameter Clearance” the 7.5 Hp looks to have relatively larger bearing clearance numbers, when compared the 3 and 5.5 Hp. The 5.5 is listed as having “Roller Bearings”, so that may explain why it’s oil recommendation went from 16:1 up to 24:1. I don’t what the justification was for the 3 Hp change from 16:1 up to 24:1.

As Einstein famously wrote “Don’t forget CD and AD use 16:1” (but maybe not for the 1963 CD)?

Improvise-Adapt-Overcome

-

This reply was modified 5 years, 4 months ago by

BRENT BERGEN.

-

This reply was modified 5 years, 4 months ago by

BRENT BERGEN.

February 8, 2020 at 10:37 am #194267Thank you, aquasonic – You have satisfied my curiosity .

That makes total sense, and my bad that I missed the difference in the rod bearings.

For some of the others that responded, and seemed to be trying to convince me, or something – I have no problem with 16:1 .

I have a couple British Seagulls that use 10:1, so 16:1 is lean, compared to that :~)

Thank you, all.February 8, 2020 at 10:49 am #194269The 5.5 horse motors didn’t get needle bearings on the big end of the rod until 1961 so 1960 and older 5.5 motors with plain bearings will need the 16:1 mix. ’61 and later called for 24:1 until 1964 when everything went to the standard 50:1 mix although I think it is safe to assume the ’61 – ’63 motors could use and survive on 50:1 as they are mechanically identical inside as the later 50:1 six horse motors which were built thru 1979.

February 8, 2020 at 1:57 pm #194285Frank,

I agree with you but must confess my Fastwin 15 was run on a plowing, not planing hull so 50% throttle was the most ever used. I was using Pennzoil 2 stroke mix back in 78 or 79. That motor ran so well!! Great memory’s!!-

This reply was modified 5 years, 4 months ago by

jeff-register.

February 9, 2020 at 10:07 am #194326

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

February 9, 2020 at 12:16 pm #194333I have the same chart Tubs has posted but I totally ignore the OMC recommended 24:1 mix given for the earlier AD and CD motors and stick with the original 16:1 mix for the older models. The 50:1 mix for the ’64 and later motors is OK as they all had needle bearings on the rod.

Notice to they say ’50:1 mix can be substituted for 24:1 mix as long as Johnson oil is used’. Was it possible the powers that be at OMC realised that sales of new six horse motors weren’t as good as expected and lots of their older motors were still being used regularly with no end in sight? Realising that a satisfied Johnson customer would probably come back and buy a new one again, slowly but surely eliminating the old motors off the face of the earth by purposefully and deceitfully shortening their life span would guarantee increased sales and profits and everything would be peachy keen again. After all, why wouldn’t they recommend the same 24 or 50:1 mix for the old TN series of motors? Possibly because they knew they would need replacing soon anyway or new parts for them were just NLA from their dealers.

Possibly I’m a bit too suspicious but I do have a box full of badly scored pistons I’ve collected over the years and the majority of them are from the 5.5 and six horse lineup. Sure, their are other causes but I also have a Fleetwin 7.5 crank and rod sitting here with close to an 1/8″ clearance on the lower rod journal. The rest of the motor was pretty worn to and I suspect it was caused by using a too light gas/oil mix.

As for the original question, stick with the recommended 16:1 mix and enjoy your summer! After all, oil is the lifeblood of any motor and is the cheapest thing you can put in it. Trying to save a few pennies now might cost big dollars later. Don’t be stingy with the oil as too much is always better than not enough!

-

This reply was modified 5 years, 4 months ago by

Mumbles.

Mumbles.

February 9, 2020 at 3:15 pm #194370No fight or argument here – I do understand and have read the many, many posts here on fuel mixes, in general, and I’m not looking for a recommendation on that.

I only wanted to know if anyone knew WHY the factory specified that particular motor for 16:1, when the others in that same list called for 24:1.

What was different about the 7.5.?The reason why the 7.5hp is singled out is because of the plain bronze bushings on the connecting rods….The 5.5 and 3hp models are set up the same way….

February 10, 2020 at 5:39 am #194417When I was a kid, I took a perfectly good-running ’56 Fleetwin, hooked up a tank of 50:1 EVINRUDE oil mix to it, at the recommendation of a professional O/B tech, and went about 1000 feet at WOT, before it threw a rod. Maybe if I had used JOHNSON oil, it would have been okay? I don’t think so.

Long live American manufacturing!

-

This reply was modified 5 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.