Home › Forum › Ask A Member › ’62 5.5 Fisherman won’t idle

- This topic has 21 replies, 8 voices, and was last updated 9 years, 3 months ago by

fleetwin.

-

AuthorPosts

-

September 11, 2016 at 5:32 pm #5224

Finally got this running in a barrel and all seems well except it won’t idle. Will run steadily in the Start position but no slower. Seems to come closest with the idle mixture needle fully closed. Thought I went through the carb carefully but I must have missed something.

Any suggestions? Would a clogged crankcase drain cause this?

September 11, 2016 at 5:39 pm #43808You aren’t trying to run that thing with the hood on, in a barrel, are you?

September 11, 2016 at 5:45 pm #43811No, hood is not on. And it’s a cool breezy day. I don’t think the issue is recirculating fumes.

September 11, 2016 at 6:09 pm #43814Could be a number of things, hard to say without seeing it in person.

Try on a boat on the lake and see how it idles.

What is the compression? How strong is the spark? Did you linc n sync?

Spark quality and strength play a major role in idle. There are many tricks to improve spark strength and thus idle quality.

September 11, 2016 at 8:56 pm #43827I haven’t measured the compression–wanted to run it first and will do it now. It feels OK.

All I did to the ignition was clean it up and set to specs. Whoever changed the coils did not dress the leads well and they had rubbed on the flywheel hub.

Frankly, I thought the spark seemed rather marginal but its been a lot of years since I worked on outboards so I don’t have a good basis for comparison. If you care to share trade secrets, what are the "many tricks to improve spark strength?"It still feels like a carburation issue to me but jumping to conclusions is not the way to go…..

September 11, 2016 at 9:04 pm #43829Use a timing fixture to set the points instead of a feeler gauge.

http://www.franksoutboardtools.com/timing-fixtures.htmlLine the coils up to the mag plate bosses using a coil locator ring.

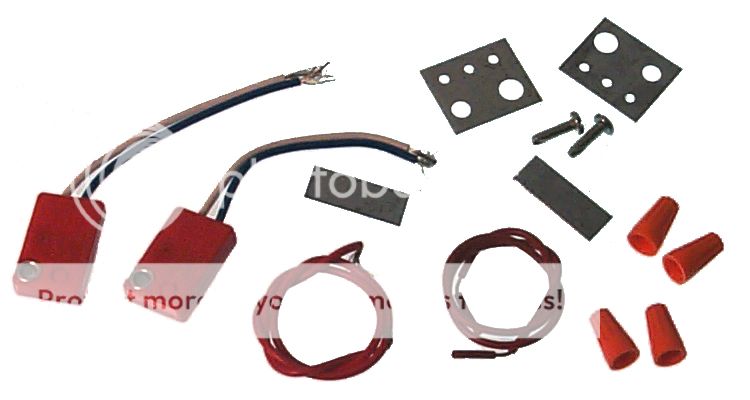

Points should be polished up shiny, and then de greased with acetone or lacquer thinner. A worn bushing on the mag plate will cause eratic spark timing, so to get around that use Atom ignition modules (if you can find them) in place of the points and condenser. Make sure plug wires are good and have good solid non corroded connections at both ends

September 11, 2016 at 9:10 pm #43830

September 11, 2016 at 9:10 pm #43830did you clean the carb idle chamber below the small round plug (part 27 on the diagram)

http://www.marineengine.com/parts/johns … etor+Groupbe certain the carb gasket does not impeed the fuel flow to the upper section of the carb via the side channel

Joining AOMCI has priviledges 🙂

September 11, 2016 at 9:20 pm #43833Agree with above. Most important thing I find is using a timing fixture. IT allows you to set the points to fire exactly 180 degrees apart, at the exact correct time, which is critical for good running motor.

Imagine a see saw with a kid on either end. The kids are the pistons, the see saw the crank. If there are 2 adults on either end helping them along (the spark plugs). If the one adult pushes down on his side before his child reaches the peak, it will be an abrubt and jerky change of motion. If too late, and his child is already on way down, there will be lost power. If both adults are pushing erratically at different times in the stroke, the whole thing will be a mess.

Now if both adults push down when their child is at the peak of their travel, with the same amount of force, equally apart, the see saw will travel back and forth smoothly and gracefully.

I realize not a perfect analogy, but you get the picture.

Correct condensors, which are not shorted, also important.

Some coils give better spark than others. Those with a Mercotronic or Stevens tester can verify this. As crappy as the Sierra coils fit, they blast a real hot spark!

Quality lead, without corrosion are important. Equally important, is the condition at either end. Properly trimmed and installed plug clips/boots, and properly twisted on coil.

You want that coil out as far as you can, without it rubbing, about a papers width away, for max spark. In conjunction with that, a well magnetized flywheel.

And as stated, don’t use the points right out of the package, polish those buggers up! Even new points have oxidation on them.

I realize I went over all of what Wedgie already stated, but I totally agree with him.

That covers the spark, but of course if compression is not up to par, or the linc n sync is off, or the fuel mix is bad, or the crank case leaks, or the carb settings are not ideal, etc etc etc, the motor just wont idle.

So there are many factors at play, and when all is as it should be, those 5.5s idle down so nice you can almost count the RPMS! Like a fine tuned sewing machine.

September 11, 2016 at 9:29 pm #43834September 11, 2016 at 11:08 pm #43844quote amuller:Finally got this running in a barrel and all seems well except it won’t idle. Will run steadily in the Start position but no slower. Seems to come closest with the idle mixture needle fully closed. Thought I went through the carb carefully but I must have missed something.Any suggestions? Would a clogged crankcase drain cause this?

Well, a clogged crankcase drain could surely cause this engine not to idle…

You mention the best it runs is with the idle needle valve just about closed…How about a leaky fuel pump? Please don’t rip into the fuel pump to test my theory, simply unplug the fuel line and let it run a bit until the fuel is out of the pump/lines…If the engine seems to clean up before it stalls, we can talk more about the pump… -

AuthorPosts

- You must be logged in to reply to this topic.