Home › Forum › Ask A Member › 6HP Johnson Seahorse – won’t idle

- This topic has 23 replies, 10 voices, and was last updated 3 days, 21 hours ago by

crosbyman.

-

AuthorPosts

-

April 18, 2020 at 11:52 am #200424

Ran OK last night at high speed w/ choke all the way in (lean) …. I did remove and check the high-speed orifice as part of the carb rebuild … confident that the carb is clean — assuming that the gasket supplied by OEM is correct.

April 18, 2020 at 11:54 am #200425Will re-check gasket if / when I get back into the carb. Used gasket supplied by OEM as part of the rebuild kit. Thanks for the picture for reference

April 18, 2020 at 11:56 am #200426Your motor has CD ignition so that wont be causing the problem but something wrong in the carb is.

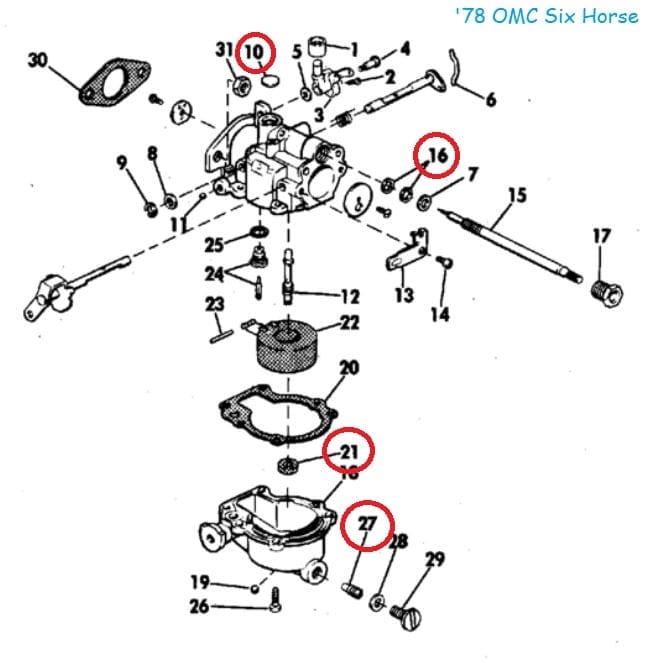

Did you use the proper OMC/BRP 439071 carb kit when you rebuilt the carb? It would have contained all of the necessary parts, including the welch plug, # 10, to totally disassemble and allow a thorough cleaning of the carb.

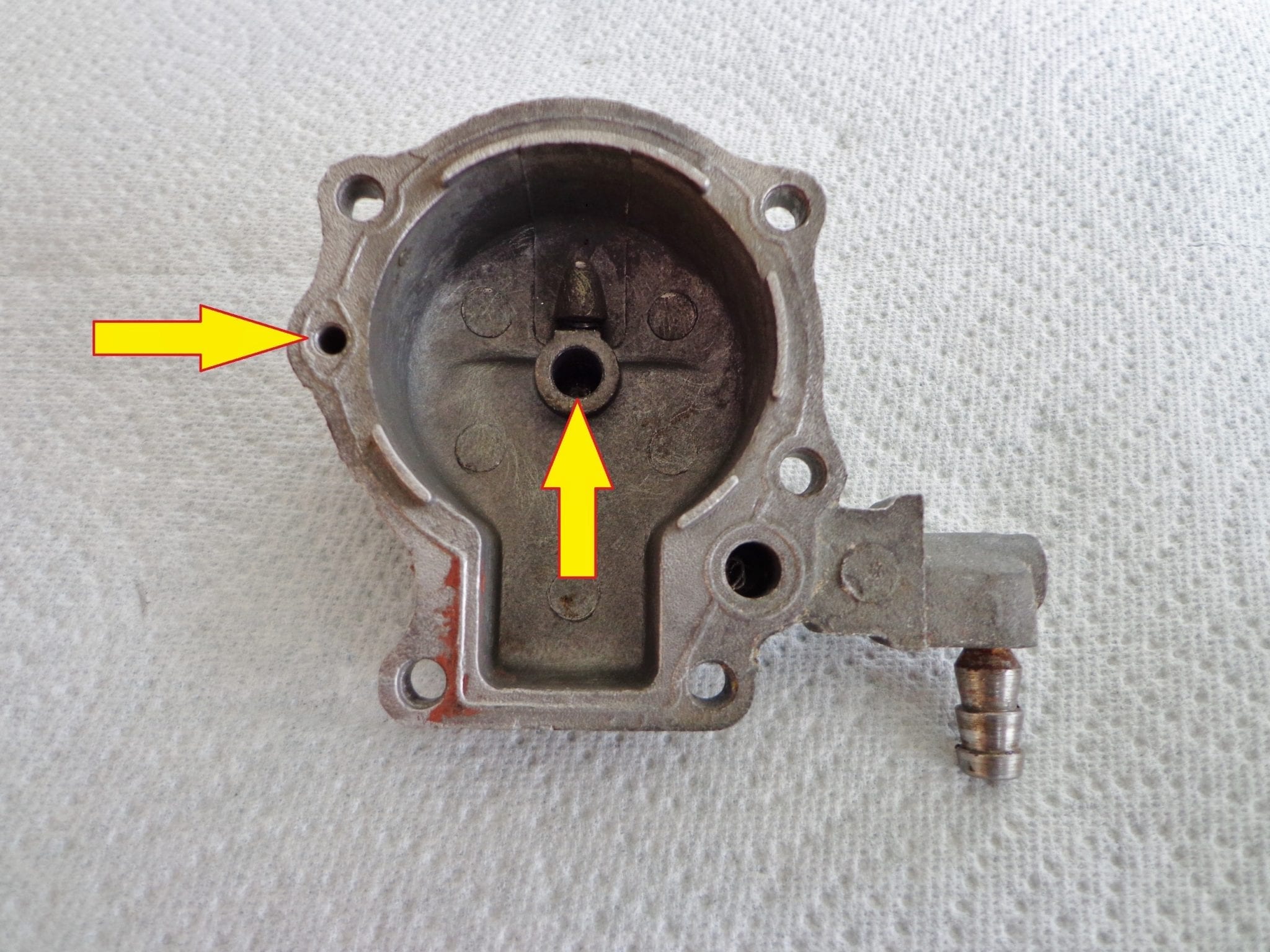

The main jet orifice, # 27, lies at the bottom of the bowl and is prone for dirt and corrosion plugging it up. All of the fuel used passes thru it so its condition is critical. The fuel passage coming from it up the side of the bowl and going to the low speed circuit can get plugged to causing idling symptoms similar to yours. Another problem area can be the condition of the low speed needle packing washers, # 16. If they are damaged, the motor wont run right as air will leak past them. If the nozzle gasket is missing, # 21, the motor would tend to run rich but yours seems to be running lean.

It’s time to go back inside the carb to double check the work you did on it. When the welch plug is removed, you will see a tiny hole which the point of the needle goes into. If this hole is plugged, guess what? No idle or poor low speed running. The carb must be blown out with compressed air after soaking to make sure all passages are clear and clean. While you are in there, recheck the float height and once the carb is back on the motor, check the synch setting between the carb and the mag.

Starting the motor with the needle about 1 1/2 turns out from lightly seated will allow it to start and it can be adjusted finer as the motor warms up. Always leave the needle a bit on the rich side from its optimum setting as this will give good throttle response and extra oiling for the motor.

April 18, 2020 at 12:11 pm #200432Thanks! — I tore the carb down to parade rest and replaced all/ cleaned all as described / pictured. May do a redo — as I have time on my hands these days. BTW — I’m looking for a motor cover gasket — old one succumbed to dry rot — I can’t find any on-line — any ideas?

April 18, 2020 at 5:12 pm #200448NY marine #4 on the list ok for you…

http://www.nymarine.ca/cowlgaskets.htm

Joining AOMCI has priviledges 🙂

April 18, 2020 at 5:43 pm #200459Did you run the engine before cleaning the carb? If so, did it idle OK? Are you sure it is running on two cylinders? The engine may sound OK when running in neutral in a barrel even though it is running on one cylinder. You mention that it ran OK with the choke in last night, were you running it on a boat in gear? Was the carb dirty/gummy when you pulled it apart, or relatively clean? Are you sure that the carb throttle plate is moving freely and closing fully at idle? There isn’t much to sync/link on this engine, the throttle cam should just contact the roller when the line on the cam bisects the roller. The carb butterfly must be completely closed when idling.

Have you done a spark check? Compression test? Is you fuel oil supply fresh, properly mixed, free of water? Mumbles mentioned that the initial slow speed needle adjustment is 1.5 turns out from gently seated, I would recheck that. Loosening the packing nut will make it easier to set the initial adjustment, gently snug it up again afterwards to avoid air leaks.

Try to post a video of the engine running/trying to idle, perhaps this will help us hear/see what is happening….April 18, 2020 at 6:12 pm #200473NIce! — Thanks

April 18, 2020 at 7:17 pm #200479This is a long (very long!) shot but is there ANY chance that the slow speed needle was replaced at some point with an incorrect one? There are many different ones and sometimes people damage one by dropping it (bending/blunting the tip) and then they replace it with one that is not exactly the same…..

When you have the welch plug out you should be able to see the tip of the needle poking through the hole when it is fully screwed in.

They don’t have part numbers on them either; makes it hard to know what you have sometimes.

Good luck!

April 18, 2020 at 9:11 pm #200489Seakaye makes a good point….Perhaps the tip of the needle valve is broken off in the carb body also…

April 22, 2020 at 10:23 am #200781Just did a compression check — it’s low — 40’s, -= believe it needs to be at least 85 ….. this could explain fuel starvation at attempted low speed I think — insufficient vacuum for fuel pump. Motor is also somewhat hard to start …. i’ll be getting into the powerhead. Ordered a brand new carb — but … I don’t think that’s my problem.

-

AuthorPosts

- You must be logged in to reply to this topic.