Home › Forum › Ask A Member › 9.9 Johnson Carb Question

- This topic has 74 replies, 10 voices, and was last updated 8 years ago by

outbdnut2.

-

AuthorPosts

-

June 4, 2017 at 1:21 pm #7226

I’m working on a 1977 9.9 Johnson that hasn’t been run for a lot of years. Gas was not run out of the motor the last time run, and from the residue in the carb, and float coating damage, I can tell the angle it was stored at, which appears to be tilted up on a boat and turned to one side. It looks like it had ethanol gas that had taken on water, because there was rust in the carb bowl bottom (made out of plated steel) even though there was oily residue there too and the submerged part of the float had the coating totally stripped off,probably from the ethanol. There was also some fine crystaline, brown stuff totally jamming the needle valve and float hinge. Found some of this in the fuel pump under the small spring, but the fuel pump input screen was clean and clear. The high speed jet was clogged with fine brown stuff that may have come from the rust – had to remove the jet, soak with cleaner and lightly scrape.

I’ve got it running good at mid to high speeds after a lot of cleaning out, but I suspect I’m not getting all the stuff out of the low speed carb passages, as I’m having trouble adjusting the low speed needle to get a good idle, but it does make some difference to how it runs. Ignition totally checks out and new NGK plugs. I’ve blown carb cleaner through all the passages I can find and the needle tip is not broken off or bent. The seal around the needle threads is good and tight.

My question is: How does the gas get to the low speed needle from the bowl? There is no passageway up the side of the bowl to clean out like older carbs. I’d like to know I’m cleaning all the passageways. I have not removed the two very small welch plugs at the top of the carb, because, so far, I have not needed a kit,and I don’t mess with welch plugs if I can avoid it.

DaveJune 4, 2017 at 1:28 pm #58943The newer carbs have a small brass tube that runs up through the venture into the area before the mixing pocket. It is hard for me to describe how the fuel is routed on the older carbs, how about posting some pictures….

June 4, 2017 at 2:14 pm #58950I thought the low speed mixture comes through the 3 very small holes in the throat of the 9.9/15carb,just above the low speed needle "mixing pocket" as fleetwin described it recently in the thread i started about the needle bearing.

I use orifice drills to check all the passages are clear, but i use the smooth end of the bit and a slightly smaller size so as not to gouge any passages. In your situation i would recommend the same and definately remove the welch plugs and clean those passages out."Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonJune 4, 2017 at 2:46 pm #58957quote pugetsoundboater:I thought the low speed mixture comes through the 3 very small holes in the throat of the 9.9/15carb,just above the low speed needle “mixing pocket” as fleetwin described it recently in the thread i started about the needle bearing.

I use orifice drills to check all the passages are clear, but i use the smooth end of the bit and a slightly smaller size so as not to gouge any passages. In your situation i would recommend the same and definately remove the welch plugs and clean those passages out.Yes the gas comes through those small holes in the throat as it’s sucked into the motor, but how does it get from the the bowl up to the low speed needle? Older OMC carbs route the fuel from the bottom of the bowl through a passage up the side of the cast bowl, through a hole in the bowl gasket to the top of the carb where it goes to the needle.

June 4, 2017 at 2:55 pm #58958outboard nut- sorry i misread your question. If you have the carb removed, remove the low speed needle, spray some gumout etc in there and blow compressed air through the threaded hole and see where it comes out?

edit"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonJune 4, 2017 at 6:49 pm #58972quote pugetsoundboater:outboard nut- sorry i misread your question. If you have the carb removed, remove the low speed needle, spray some gumout etc in there and blow compressed air through the threaded hole and see where it comes out?

editI did that last night and, besides coming out the little holes in the carb throat, it comes back through the high speed metering jet. I took the high speed jet out and did that again and it looked like it was coming from around the brass tube that is the main venturi tube in the casting above the jet.

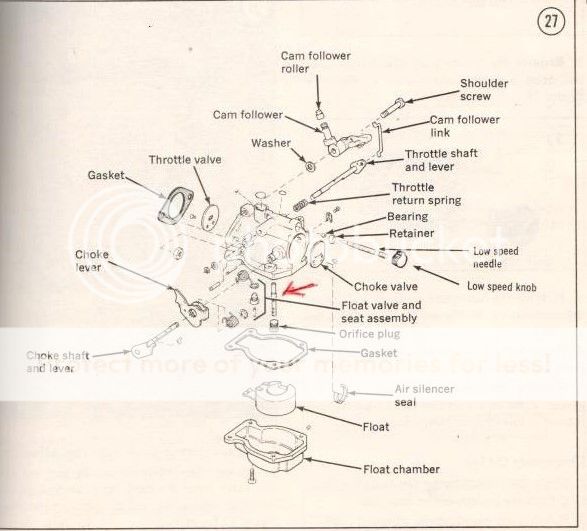

I just found an exploded view in an old 1978 Clymer manual (see below). It shows (see red arrow) that the brass tube has a couple of holes near the bottom and one more a little over half way up. The holes in the bottom would be sitting in gas as they are below the float level of the gas. The hole farther up may go to a passage in the casting to the low speed needle, but I can’t tell form the drawing – see the red arrow below. What doesn’t show in that view is that the brass tube is fully encased in a cylindrical casting coming down from the center of the carb top, and the main jet (called an orifice plug in the drawing below) screws into the casting underneath the brass tube. I can’t find a good way to direct pressure from the carb cleaner tube through any passage to the needle to force dirt out. Maybe I have to pull welch plugs which a newer Clymer manual refers to as "Lead Shot".

Problem I have is I can’t get the motor to stay running when I idle it down to backtrolling speed. It runs best with the low speed needle 2-1/2 turns out and that is a bit far and still not good enough (manuals say to start one turn out). Also – this 1977 carb linkage does not have the little adjustment screw on the throttle linkage roller-cam follower that newer models have – I may be able to get a better idle if I could adjust the min throttle plate opening ever so slightly – I’ve had success on late 1980s motors with this.

Also open to other suggestions to make this thing idle right – I’ve wasted way to much time on my friend’s motor!

A couple years ago I worked on a similar model for a neighbor that would not sustain an idle and switching from Champion to NGK spark plugs very magically fixed it. I already have NGKs in this one. It just occurred to me I could have a bad new spark plug – I’ll try another set. I’m about out of stuff to try! It runs really good at fast idle and above.

Thx

DaveJune 4, 2017 at 7:57 pm #58977Ok – per my post above, I tried spark plugs that work fine in another motor like it – no change!

Unless I get other suggestions, I think I will have to take the carb apart again. The low speed needle is just not getting quite the response it should.

DaveJune 5, 2017 at 8:19 am #59012You are sure that you have the low speed needle bearing in there? I had one that wouldn’t idle,the bearing was missing.

I have never removed the lead shot,look kinda tough to get out and reseal with a new one.

Did your friends motor ever idle well,or is this a new occurrence?"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonJune 5, 2017 at 9:44 am #59013Let’s all hope it’s just the carb or linkage adjustment; but if it were me, I would do a quick compression check to make sure I knew where I stood with the power head. These engines are famous for over heating, especially in salt water areas. I don’t know if this is the case with you…

Long live American manufacturing!

June 5, 2017 at 2:21 pm #59031Thanks for the tips!

This is not a salt water motor, and it’s not overheating.

My friend just bought this and was told it hadn’t been run for many years, so past running history is unknown.I totally missed in the diagram that the carb has a bearing on the low speed needle – never heard of that before – I’ll check that. Is this something I can see with a bright flashlight looking in when I remove the needle? or "feel" poking a stiff wire with a small bend on the end in there? if not, how do I check for it?

I’ll check compression too.

I’ve never removed any of those lead shot plugs either and hope I don’t have to

Here’s a thought that came to me last night – I’m wondering if it’s possible that at slow idle, one cylinder is dropping out, maybe from a week coil or corroded coil ground connection? There is visible rust/corrosion the bolt at the top of the upper coil and that has ground wires, etc under it. I had it running first in a barrel, then when I put it on a boat, the fast idle "seemed" good but it was runnin’ on one cylinder when I went to WOT. After running a couple minutes, I dropped to an idle again and back to the dock. I shut it off briefly and then took it out again and both cylinders kicked in and WOT was great,and fast idle improved also. I’m thinking maybe the corroded ground connection got "flexed" as the motor heated up and metal expanded, squeezing/flexing connections to the block making for a better ground and that may have activated the 2nd cylinder. I’m thinking maybe at a slow idle, the ground still isn’t good enough, and that cylinder kicks out? I’ve never heard of this before, and it sounds a bit far out, but I’ll take apart and clean up the ground corrosion under that bolt and see if it helps.

Dave -

AuthorPosts

- You must be logged in to reply to this topic.