Home › Forum › Ask A Member › 9.9 Johnson Carb Question

- This topic has 74 replies, 10 voices, and was last updated 8 years ago by

outbdnut2.

-

AuthorPosts

-

June 5, 2017 at 4:28 pm #59052

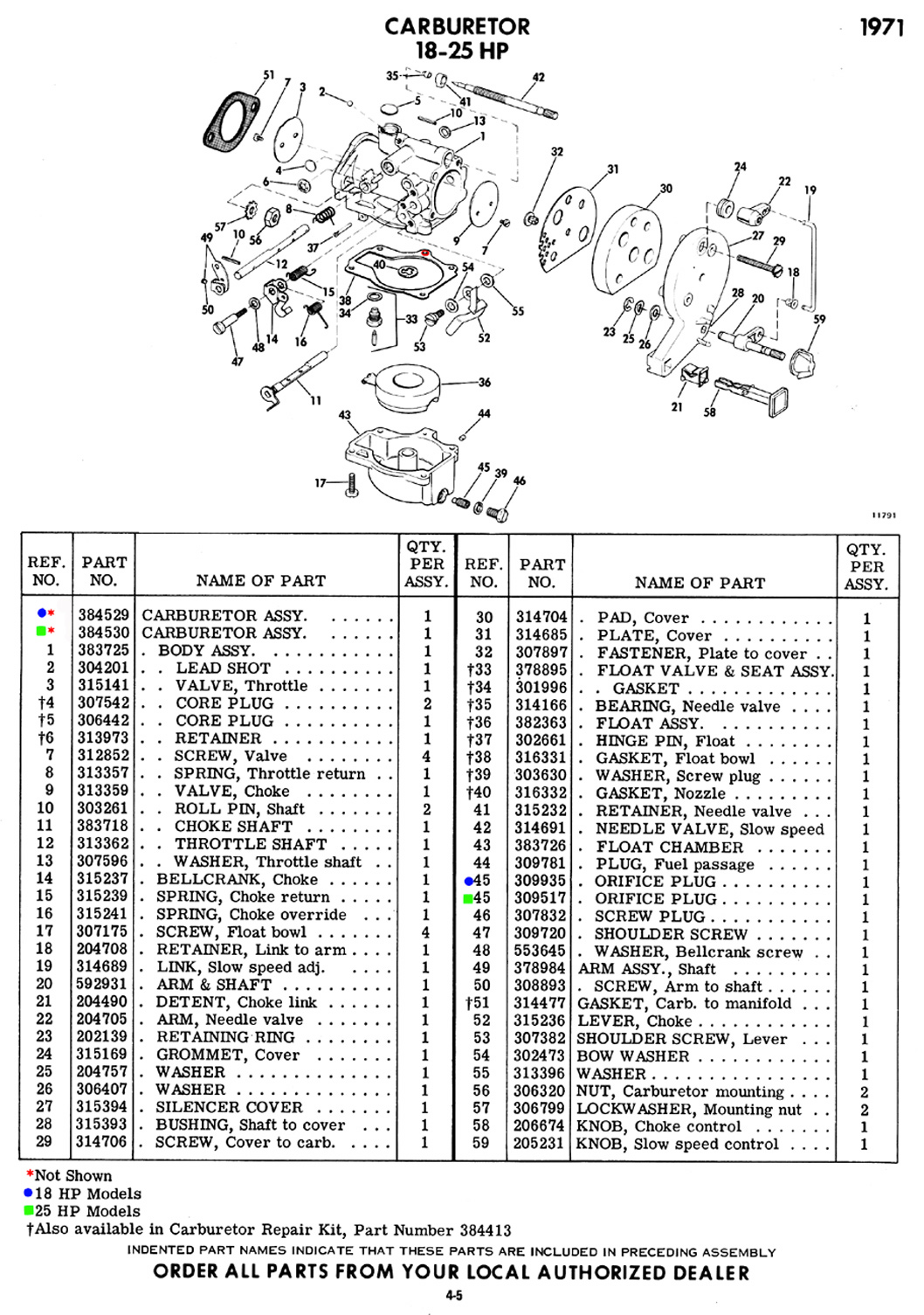

It may need the nozzle gasket 0316332 ? . . . 🙂

Many carburetor changes over the years.

June 5, 2017 at 8:12 pm #59066

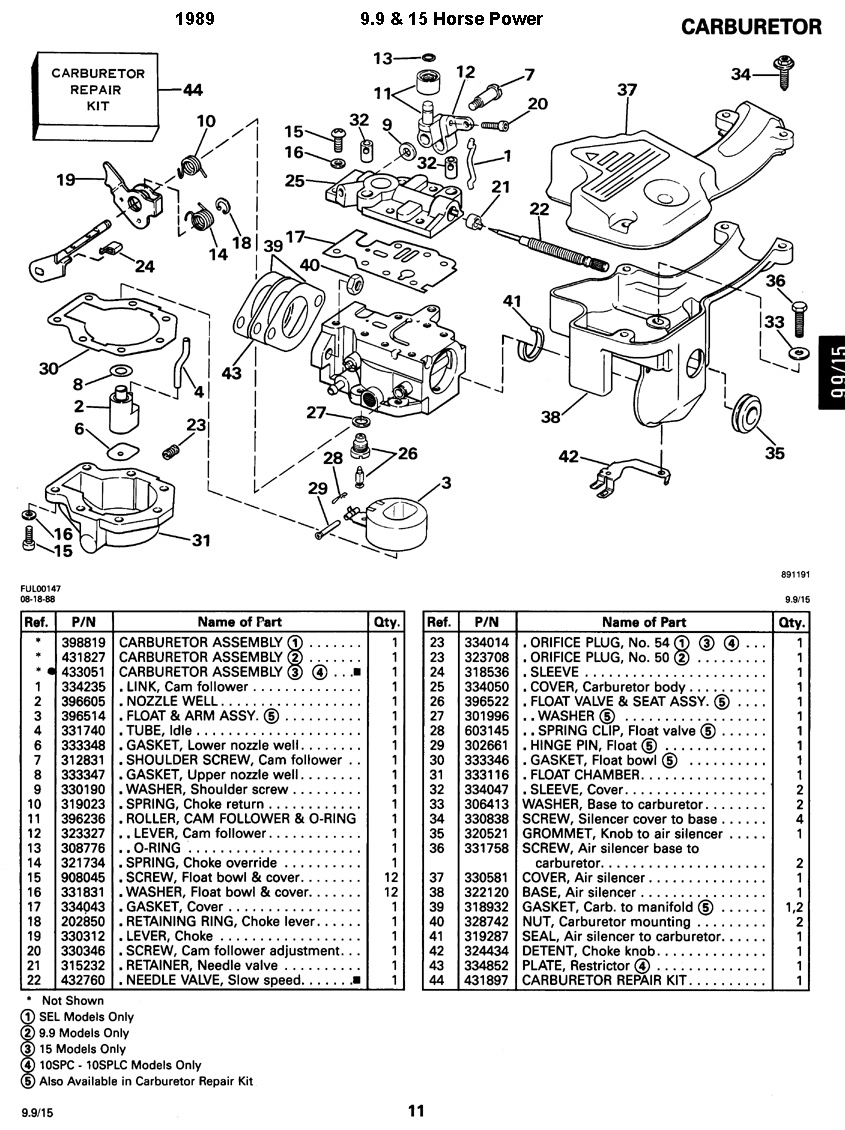

June 5, 2017 at 8:12 pm #59066Thanks Garry, but the carb in this 9.9 doesn’t have that nozzel gasket and it is not like either of the ones you posted. The bowl bottom is just a piece of stamped sheet metal. See the view I posted in page 1 of this string. I agree – there have been a lot of changes to these 9.9 and 15 carbs.

DaveJune 5, 2017 at 9:23 pm #59069Anything is possible, never overlook the simple/basic things. I would definitely clean up all those grounds and restest…

You need to figure out whether the engine is misbehaving at idle because it is dropping a cylinder, or because the carb is messed up…June 5, 2017 at 10:19 pm #59072I just finished cleaning all the ground connection interfaces under the coil bolts with a wire brush -I knew it was a long shot and it did not help. I’ll check compression tomorrow. If all else fails, I’ll attempt to temporarily swap a carb onto it from one of my good running, slightly newer, 15’s just to see if the problem is indeed in the carb. The linkage is a bit different, but I think I can do it.

DaveJune 6, 2017 at 3:25 am #59100Good plan, using a known good carb will answer many questions quickly!

June 6, 2017 at 4:19 pm #59129I’ve wasted way too much time on this motor lately. I’m going to loan my friend a motor to fish with for awhile and let his 9.9 sit for a week or so. AT this point, I need to get in a better frame of mind to work more on it.

Also – 9 motors followed me home last week from a batch of about 30 a friend came up with cleaning out his Dad’s garage. I’m anxious to see which can be restored and which are parts motors.

DaveJune 7, 2017 at 12:38 pm #59187I can’t say it will fix your problem but if I was having a slow idle problem I would definitely remove the welch plug and the slow speed needle bearing and clean them cavities out well and replace them with new ones. It is not difficult to do and the parts are maybe worth $10 in total. Keep in mind that the slow speed needle bearing is made of plastic and plastic parts are not fond of carb cleaner. A little is fine but maybe someone soaked that thing in carb cleaner over a few days. Not sure a plastic bearing would hold up well with that. In any case, just replace it. Might as well replace the retainer needle valve as well. It is also made of plastic and is critical to maintaining a good seal. If air sucks past that it will never idle well.

June 7, 2017 at 2:58 pm #59199quote OptsyEagle:I can’t say it will fix your problem but if I was having a slow idle problem I would definitely remove the welch plug and the slow speed needle bearing and clean them cavities out well and replace them with new ones. It is not difficult to do and the parts are maybe worth $10 in total. Keep in mind that the slow speed needle bearing is made of plastic and plastic parts are not fond of carb cleaner. A little is fine but maybe someone soaked that thing in carb cleaner over a few days. Not sure a plastic bearing would hold up well with that. In any case, just replace it. Might as well replace the retainer needle valve as well. It is also made of plastic and is critical to maintaining a good seal. If air sucks past that it will never idle well.Thanks for the info about that bearing. Up until I came across this thing, I never hears of one being there. I will try another know good carb (borrowed form a good running motor) and if the good carb works, I will take the welch out of the bad carb. I have a lot of various size welch plugs left over from many carb kits where I didn’t need to pop them out, so I’ll find something that works. Is the bearing and retainer in OMC or Sierra kits? or do I order that separate?

DaveJune 13, 2017 at 3:22 pm #59609Sorry for the delay. They should all be in a kit but you can order them separately as well.

June 14, 2017 at 12:06 pm #59670I have noticed that magneto timing on these motors is also very important to get them to idle correctly. When the carb roller cam follower is lined up with the timing index mark (not really sure what mark on timing plate is called that roller rides on to open carb) the carb butterly should be shut and be on the verge of opening once you advance the timing a tad more. The carb butterly has to be shut when lined up with that timing index mark to make the carb use the low speed circuit correctly at idle speed on those particular motors. I have almost pulled my hair out getting mine to idle correctly that was a crucial part of it.

The bearing needle valve and the needle valve retainer must also be in good condition for a good idle. As someone mentioned carb cleaner destroys them. I destroyed a brand new needle valve retainer in seconds with carb cleaner.

Good grounds on all ignition components are also critical as you mentioned. All 3 of mine were salt water motors and the grounds especially for the ignition coils had to be cleaned up with sand paper and a file. If in doubt thoroughly clean all the grounds then you can rule that out. The component might be bad but not the ground.

Just my 2 cents and I hope that helps,

Joe

-

AuthorPosts

- You must be logged in to reply to this topic.