Home › Forum › Ask A Member › 9.9 Johnson Carb Question

- This topic has 74 replies, 10 voices, and was last updated 8 years ago by

outbdnut2.

-

AuthorPosts

-

June 17, 2017 at 1:43 am #59805

Out of the 3 I worked on the 1991 carb was the easiest for me to dial in. It has the adjustment screw to allow it the butterly to be tweaked while running at idle speed and dialing it in. It has like a SS hex head screw on it to make adjustments even while running tells me that was done for a reason. I will post the diagram of 1991 carb. It also had a totally different look and build to it. You can look for yourself but out of 3 I own I got the best results with this particular carb. I was working on like a 75,85,91 . The 75,85 had a carb like yours not much difference in them. The 91 best I could tell did not have the bearing needle valve it was eliminated (?). If at all possible try a 1991 style carb. I did notice that the low speed needle had to be turned out more on the older style carbs like 2 1/2 + turns to get a good idle. I did swap carbs while working on engines a 15hp carb compared to a 9.9hp carb in my humble opinion are almost identical except high speed jet size and yours is running well at high speed that would be the size you need if you tried a 15hp and it wouldn’t run high speed well. I measured carb throat sizes on 9.9 and 15s and they were very close.

Like Fleetwin said you can tweak when the butterfly opens or not to see if that helps and make sure throttle butterly is closing all the way not a weak spring. Check your reed valves also to see if their closing properly no light coming thru when they are closed.

Hope that helps,

Joehttp://www.marineengine.com/parts/johns … Carburetor

June 17, 2017 at 1:55 am #59807After spending 3 years on my 76 here are my thoughts on these older carbs..I have had to set the float level slightly higher with the aftermarket plastic floats for the idle to be right on these first carbs. It would lean stall when throttling back. I wonder if the cork and plastic floats are actually equivalent. I got this tip from a member here I think.. The following story is for my 15hp but might be of some help..

I took out some cam lift from the beginning to about 3/4 or just where the cam starts to curve up. Not sure what cam you have on that 9.9..I can’t see how there can be a smooth transition from fully closed to just opened. So I set the roller at the vary beginning of the cam to just have the carb barely opened. I soldered the 2 holes closed on the butterfly and filed a flat on the top of the butterfly as the later ones have. It now runs better than ever. Even the wife commented about how smooth the motor runs when docking and such.

When I first got this motor 3 years ago all apart in a box it had a piss poor carb setup with it. I have spent hours on that carb..looking at ebay pics of carbs and looking at every carb exploded view I could for these motors. I have had it apart I betcha 20 times in 3 years and have made many changes that were a step back..

June 17, 2017 at 2:10 am #59808I am not sure if the 1991 would bolt up to a 76 that would need checking. Sounds like you have a great deal of experience with these motors. I will say I was challenged with getting a good consistent idle with these motors. I sold every one of them this winter in the Keys. I wasn’t a fan of them. I am a fan of the 9.5s .

Hope you get it fixed. I like the mods you did to your other carb. Very interesting. My buddy purchased my motors he is a live aboard in key west. I will keep that in mind if he has a problem he uses one of them daily.

Joe

June 17, 2017 at 2:31 am #59809I believe the motor your working on doesn’t have points so you can’t use a timing fixture on my buddies 1961 50hp Mercury when the throttle started to open the points needed to open or it would stall not really your problem but interesting about timing of ignition verses carb. I was thinking what if you took off the cam roller on carb and adjusted timing to see if you could get a good idle if you find it then you would know when butterfly needs to open. I think one of mine I actually had the low speed screw turned out like 4.5 turns letting more fuel in at idle. Just wonder if that might help.

Also when I slow down an outboard I do it slowly and let everything catch-up since its all mechanical. I am sure you do also but I have had to show folks that when operating an outboard.

Joe

June 17, 2017 at 2:46 am #59810The later 93 and up intake has a passage between the intake runners just before the reeds. And only a half baffle at the carb. Look at intakes on ebay or images and you will see the difference. The op has a 77 and has electro ignition. The position and size of the holes under the welsh plug are another tuning tool.

The unequal intake runners with a single carb I suspect is causing resonances at low rpms with that motor. The changes to the intake in later years might be an attempt to clean up the lower rpm.

June 17, 2017 at 2:59 am #59811When I was young I didn’t even know an outboard could run well at low speeds. I thought we were flying if it would go well at high speeds lol. As I get older I appreciate knowing that they also run well at low speeds when everything is working together in harmony. A lot more goes into that and I think its a great challenge but can be very frustrating to get there. But when you do its an awesome feeling. Nothing like it.

Not many reed valves worth checking to see if they might not be sealing correctly to rule it out or rule it in.

Joe

June 17, 2017 at 3:15 am #59812A lot like getting an over camed 4 stroke to idle well enough..

These motors really needed 2 small carbs though ;)..I still haven’t ruled out trying a single Mikuni slide valve carb just to see how that works.

Hope all this off topic helps the op..

I have used cc reeds last year but they burnt quickly. This year I have Boyesens and I will see how long they last.

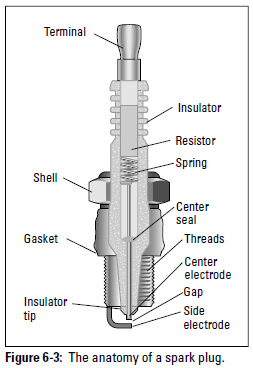

June 17, 2017 at 3:32 am #59814Someone here might elaborate on this more about spark plugs.

One thing I did do to the 1975 this past winter was a trick I learned in a Scott Atwater manual to the NGK spark plugs I had in it. It was called old timers tricks in a manual written in 1950. 1 trick that I applied was this Champion would call their plugs like J6J or J6C the J at the end meant the side electrode was ground half-way back to where it was only covering half way over the center electrode making the fire jump in a sideways motion. I filed my NGK plugs to that patern and it seemed to help at idle making plug less likely to foul.

The other old timer trick was to mark the spark plug where the insulator curved tip is on outside of plug and when you install plug make sure the mark is in the down position even if you have to put in a second washer this helps a cylinder that is fouling. It also mentioned widening the plug gap on that cylinder also a tad.

Just something to ponder,

JoeJune 17, 2017 at 3:54 am #59817Yup..I index the ground electrode towards the intake as I use the older, higher comp head. I side gap the plugs at .030. The half ground electrode as I understand is to help keep carbon chunks from getting caught in between during the days of 40wt auto oil. Since point to point is ideal for easy spark I side gap and point the ground electrode. The older head showers the plug with intake juice so I use a b6 on top and a b5 on the bottom. ngk of course..

June 17, 2017 at 5:01 am #59822I have learned a lot on this thread especially page 4 . I have tried to index the spark plugs also on my ’76 9.9. So i should have the ground electrode at the bottom,with its point facing up to the center electrode?

thanks,Jim PSB"Some people want to know how a watch works, others just want to know what time it is"

Robbie Robertson -

AuthorPosts

- You must be logged in to reply to this topic.