Home › Forum › Ask A Member › Adapting CD Magneto To Points Style Block

- This topic has 7 replies, 5 voices, and was last updated 4 years, 10 months ago by

fleetwin.

-

AuthorPosts

-

April 14, 2019 at 12:16 am #173279

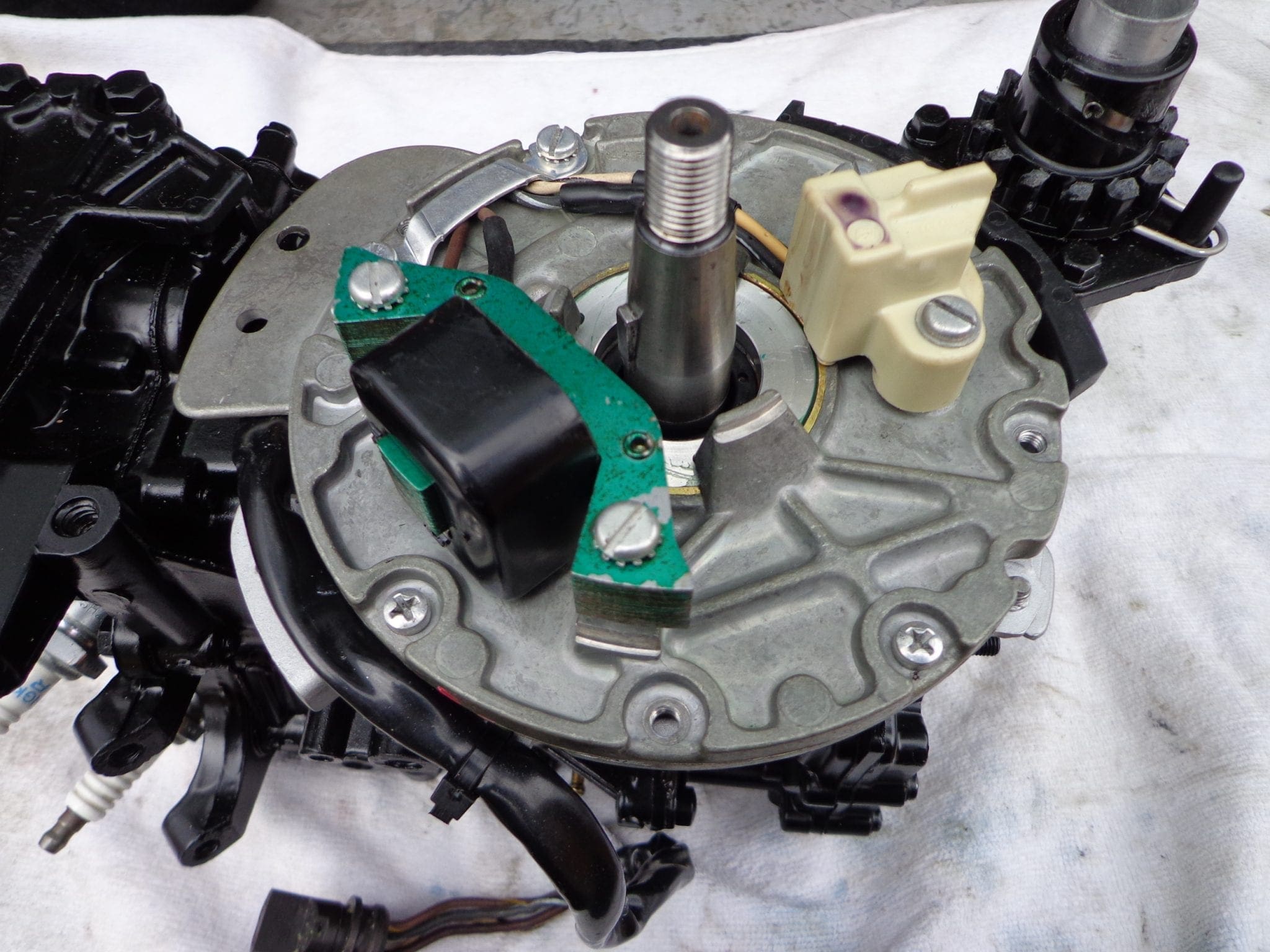

After assembling a replacement powerhead for a ’77 six horse I’m building, I realized the block had the smaller bearing boss on top as found on the ’76 and earlier motors which used the universal points style magneto. Wanting to keep it correct, the choices were to find and rebuild a ’77 – ’79 block with the larger boss or figure out a way to adapt a CD magneto to the freshly rebuilt RPH powerhead I had just finished. I chose the second way.

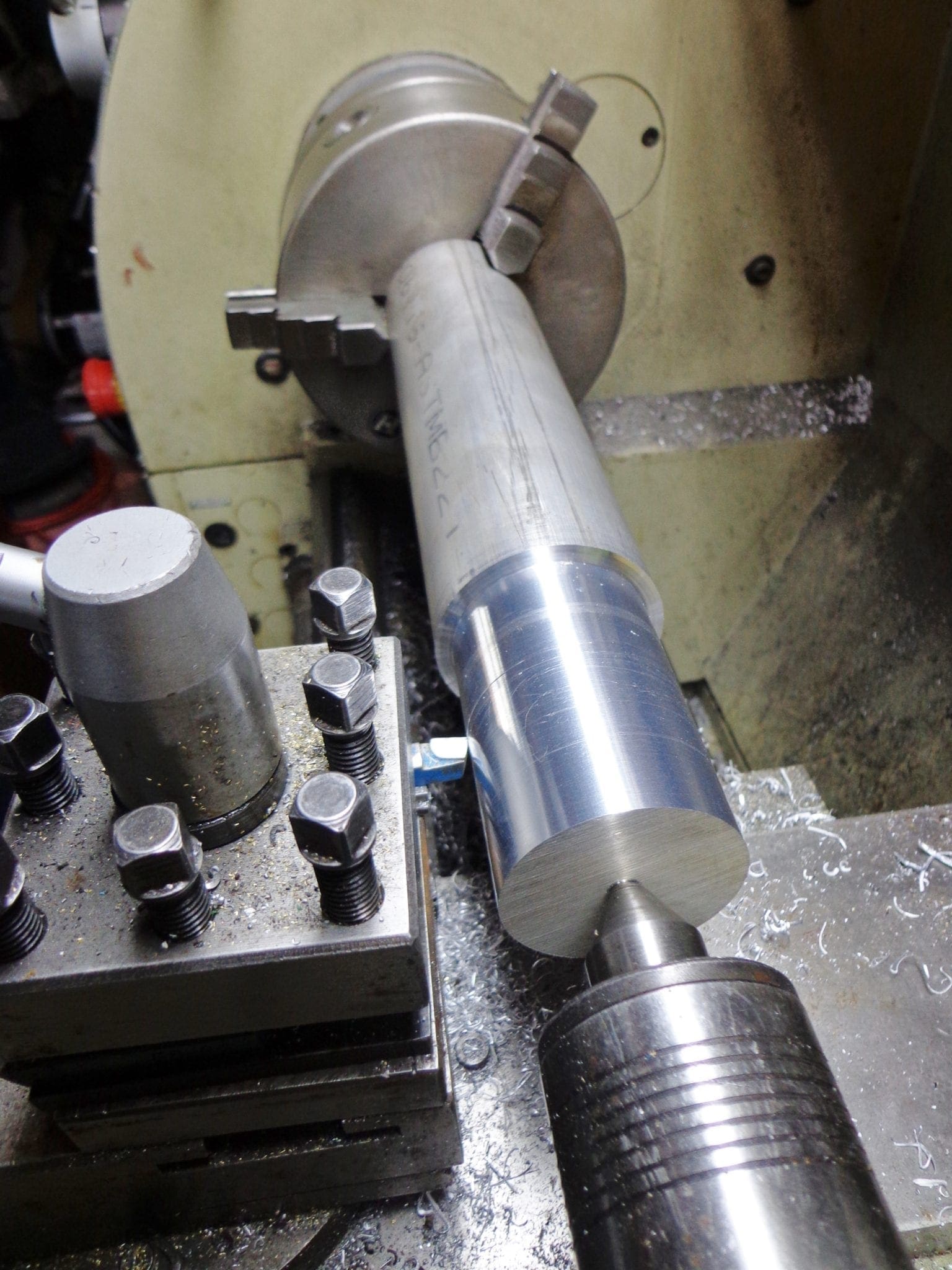

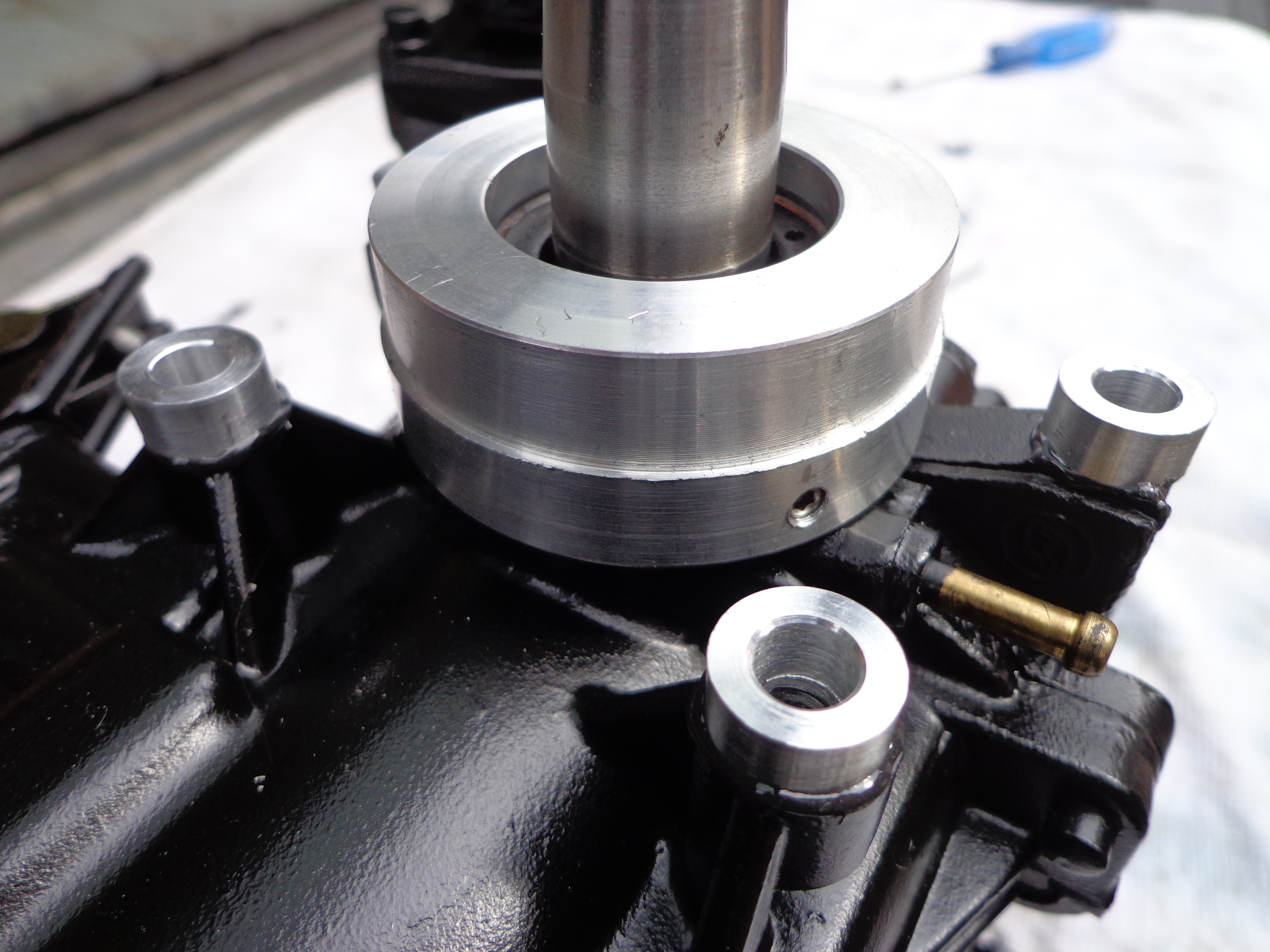

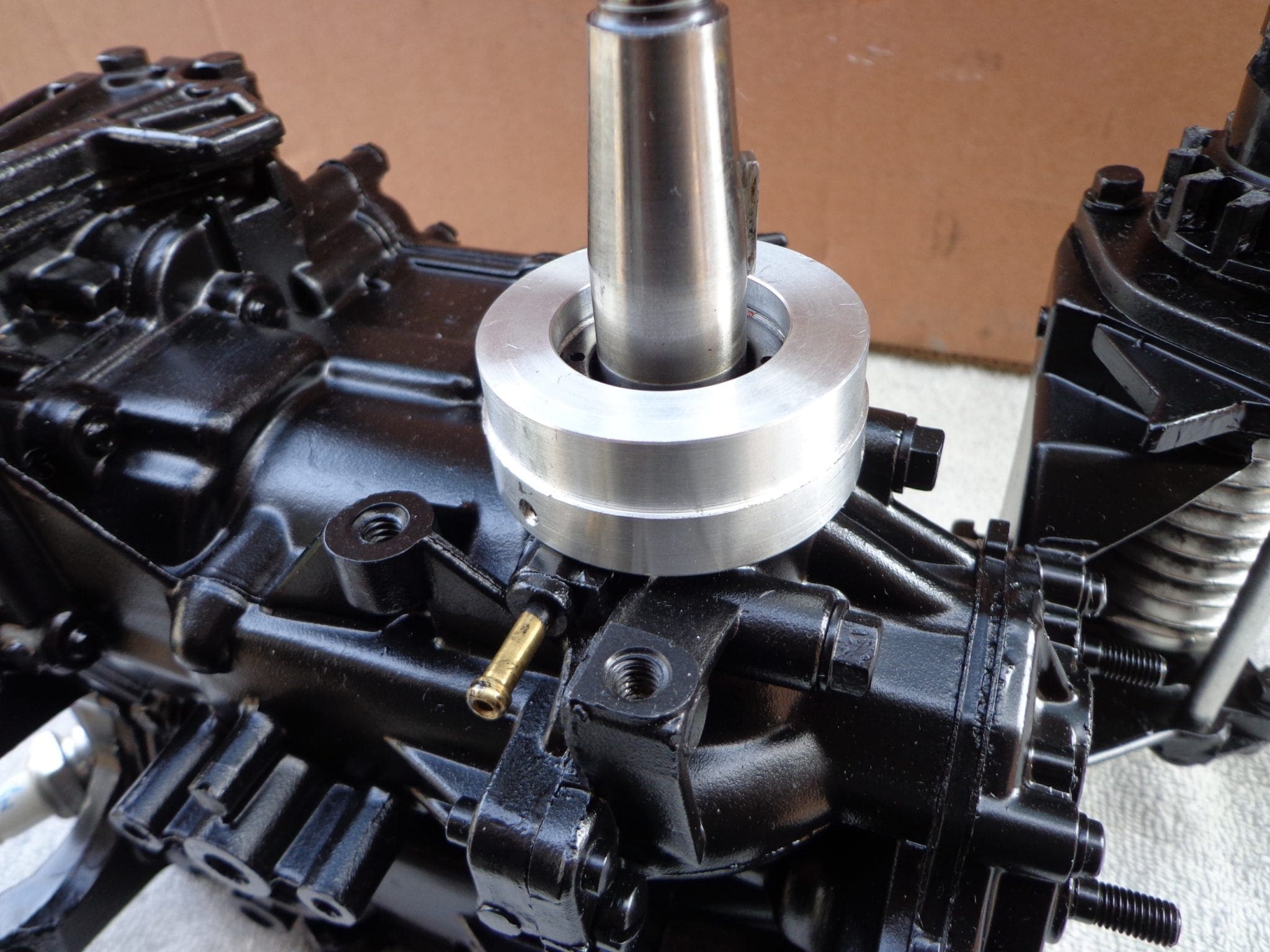

After comparing both types of blocks and doing some careful measuring, it struck me that it just might be possible with a custom bushing. First, I turned down some 2 1/2″ aluminum round bar to size and bored it out for a good fit over the small bearing boss. Three 8/32″ stainless set screws evenly spaced around the base will hold it in place.

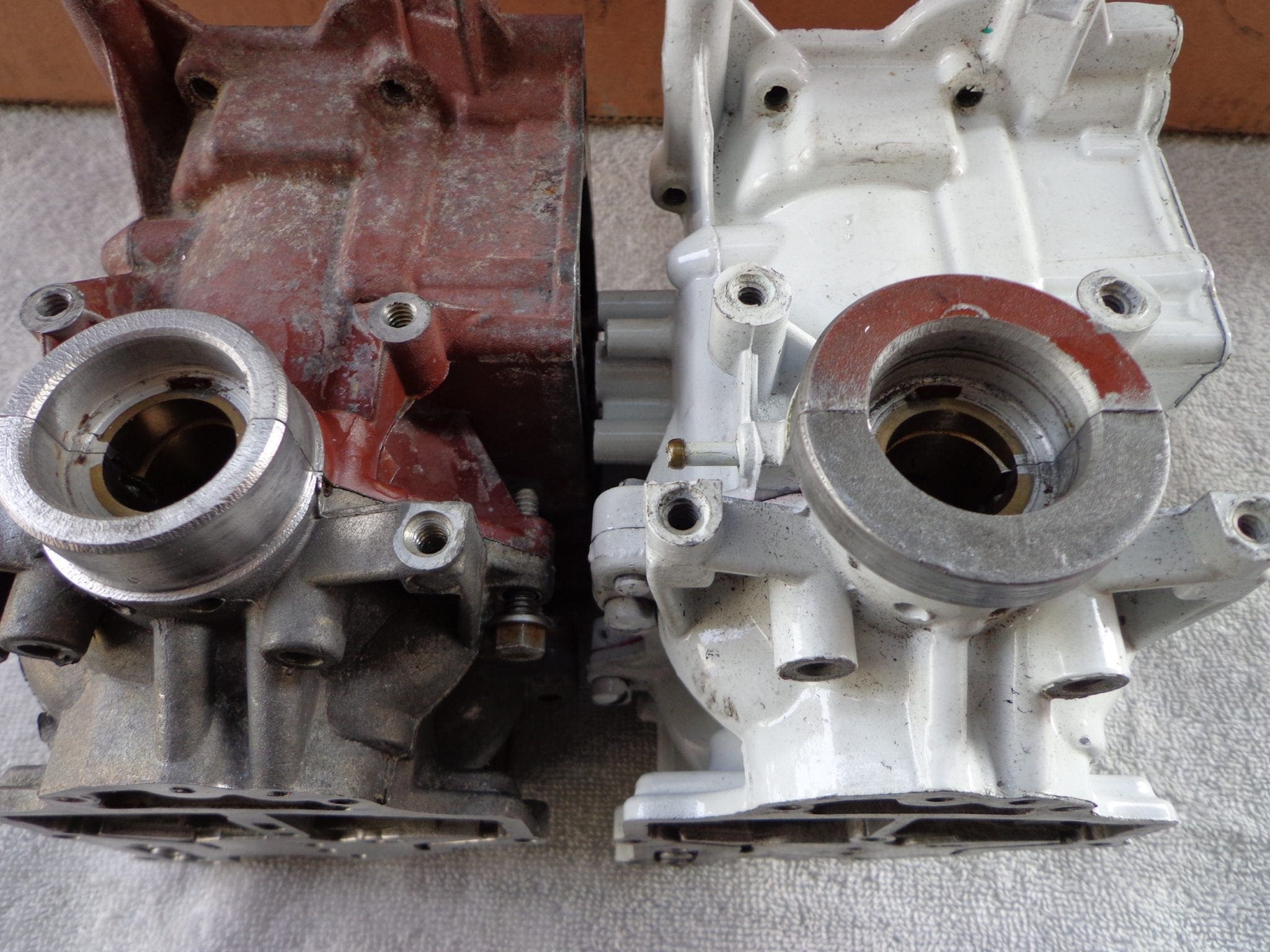

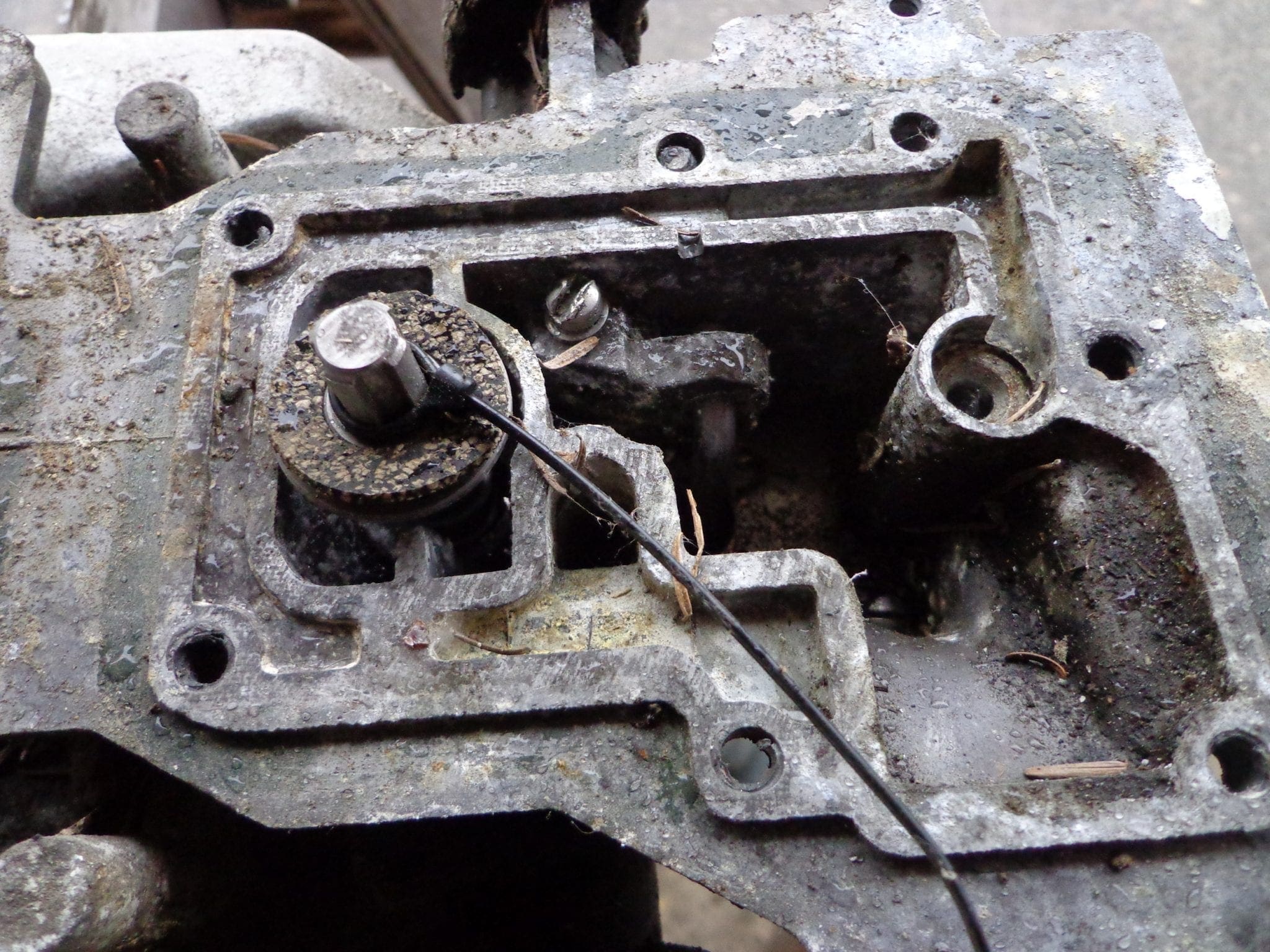

Here you can see the difference between a points mag bearing boss on the left and a CD one on the right.

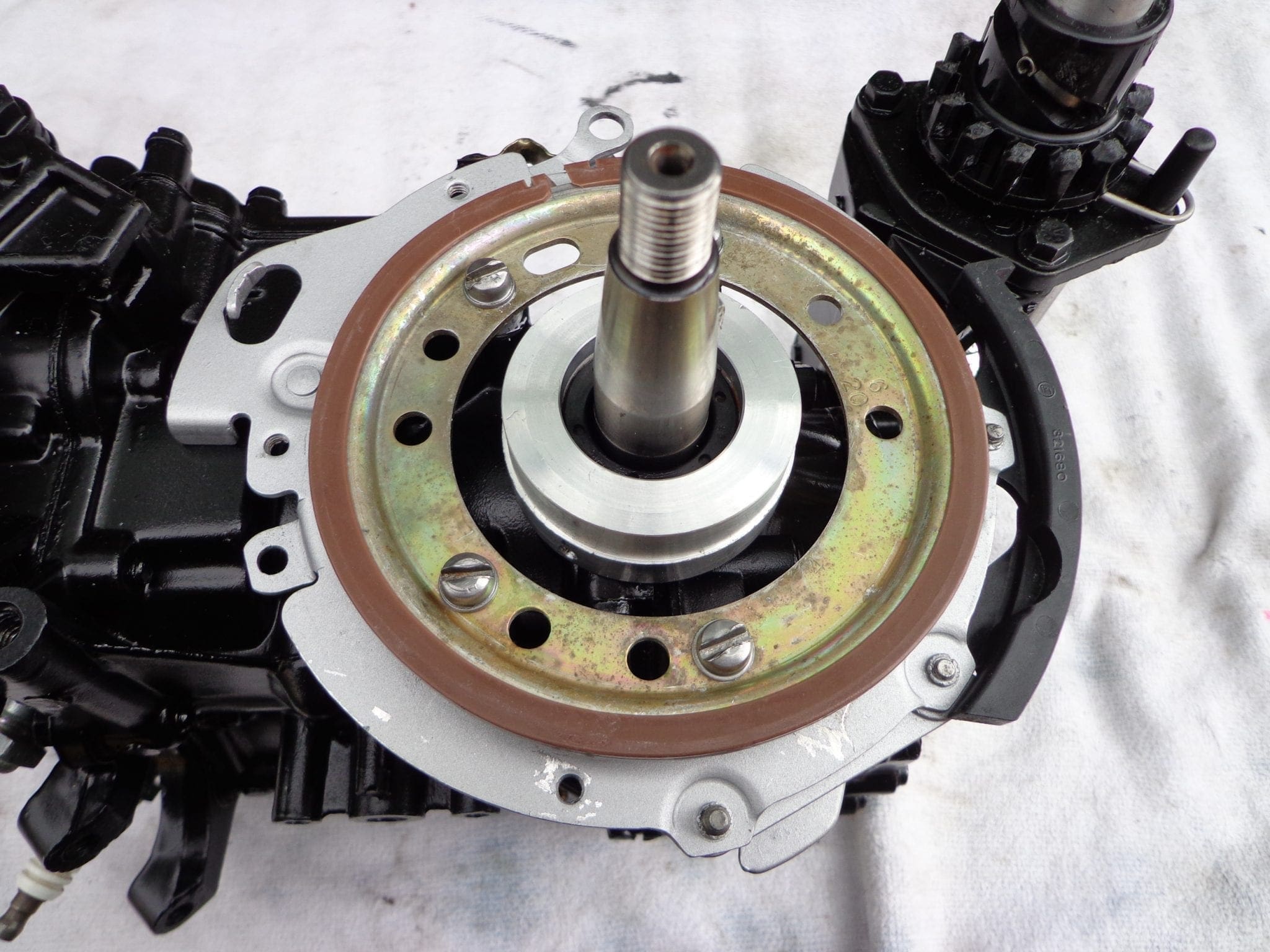

The new bushing fit perfectly on the fresh powerhead but four 1/2″ spacers were needed to keep the mag plate at the correct height. The heads of the new retaining screws needed to be thinned down a bit to for clearance between them and the mag plate.

This fix should work as the motor turns over freely with no signs of interference or binding anywhere. I know it would have been a lot quicker and easier to have used a points magneto but like I said, I want this one to be correct!

April 14, 2019 at 12:23 am #173287April 14, 2019 at 8:28 am #173300Great work!

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."April 14, 2019 at 8:34 am #173301Great Work-around! The lathe, greatest invention since the wheel!

Prepare to be boarded!

April 14, 2019 at 8:55 pm #173403Boy, that is beautiful engineering/machining work indeed….The OEM retaining screws for that retainer plate are lower and won’t interfere….

http://www.marineengine.com/parts/johnson-evinrude-parts.php?year=1977&hp=6&model=6704M&manufacturer=Evinrude§ion=Magneto

#41 304442

Can’t wait to hear this little gem run, what happened to the original powerhead/crankcase??May 25, 2019 at 8:04 pm #176037I couldn’t use the original retaining screws Don as they would have been too short with those 1/2″ spacers which were needed under the armature plate. Some 1/4″ machine screws with the heads turned down a bit did the trick. The freebee ’79 donor motor never came with a powerhead. It’s a good thing I have a few parts for these motors including a couple of RPH blocks in mint condition and NOS pistons and rings put away. The new ’77 decals and cowl seal are here but I’ve been having a bit of trouble with a run or two in the paint. It has to harden for a few more days before I can sand it out and recoat the hood. At the rate I’m going, this motor should be ready for some trout fishing in the fall!

May 26, 2019 at 1:23 pm #176072Looks impressive so far, great work!

It's a jungle out there.

May 27, 2019 at 7:57 am #176097Oh yeah, forget about those spacers you had to use…. Save those before pictures, no one would believe it once you are done….The engine sure will be ready for fishing in the fall, and many more in the future….

What kind of media blaster do you use/have? So sorry that the paint ran a bit, I can only imagine the hours that have been dedicated to this project. Will you keep this engine for yourself, or sell it? -

AuthorPosts

- You must be logged in to reply to this topic.