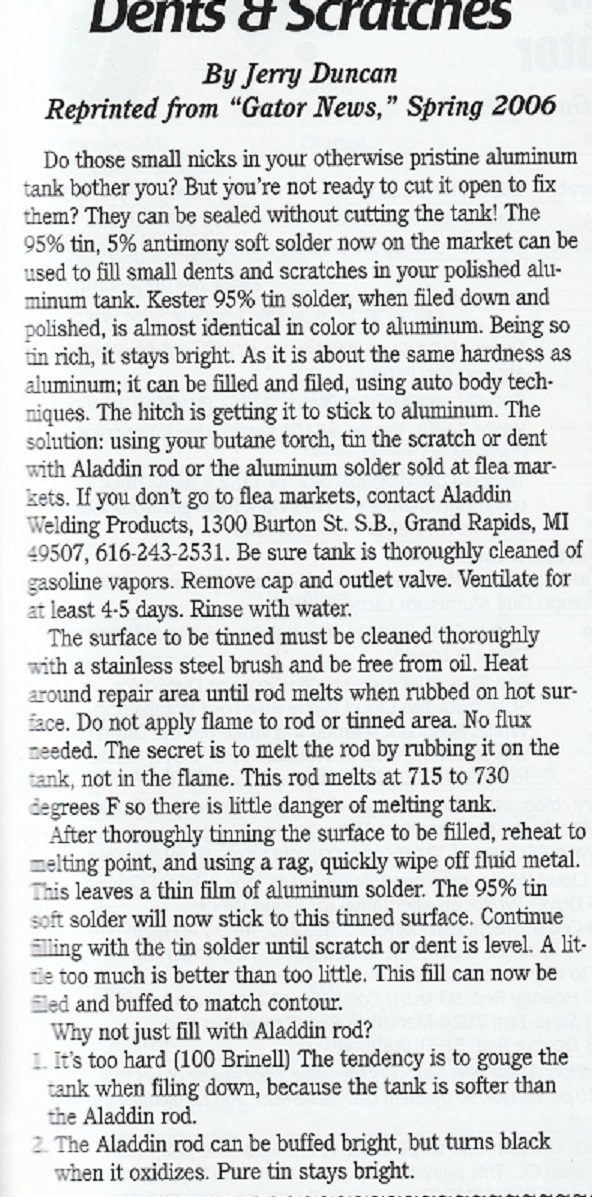

Home › Forum › Ask A Member › Aluminum tank dent repair with solder

- This topic has 10 replies, 3 voices, and was last updated 2 years, 5 months ago by

Tubs.

Tubs.

-

AuthorPosts

-

August 23, 2023 at 11:12 pm #279657August 23, 2023 at 11:35 pm #279660

Interesting tip, thanks for posting that , Bucc. From my knowledge if the materials sited, it should work as advertised. The Alladdin ( flea market) rod is mostly zinc and yes is much harder than aluminum and wil turn dark with age, I’ll have to give it a try.

Joe B

August 24, 2023 at 11:11 am #279662

I have some experience repairing aluminum

square tanks and have used the aluminum

brazing rod on a few occasions. How much it

shows depends on how the light hits it.

My limited experience is, polishing keeps it from

graying. Getting enough heat in the part to get

the stuff to stick is a challenge for me. If I

can overcome that applying solder would make

getting a level surface much easier.

I saw your gas tank repair last week in projects

and got me motivated to start on this one I

need to get done. Didn’t last long though as it

been sitting on the floor ever since.

Tubs

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

August 24, 2023 at 1:21 pm #279668Holy Cow, that tank looks like a challenge!

Did you use “air only” to get the major dents out?

Looks like you had the tank well caged.Prepare to be boarded!

August 24, 2023 at 7:39 pm #279694

My approach is to work on one section at a time regulating the air pressure

to push the surface out. Then, using mostly my plastic hammer, I knock back

the high points, thereby bringing up the low spots. Success varies.

Several times I thought I had this all figured out only to learn that I don’t.

Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

August 25, 2023 at 9:14 am #279712Tubs has the right approach, there is a real risk of turning the tank into a “football” if high air pressure is used absent the flat constraints. I attended a seminar at Constantine last July put on by Jay Walls about tank restoration, he made the point about too much pressure with out restraints. Another approach that is referred to in that old Jounsom shop manual is to use low pressure ( 3- 4 PSI ?) and apply heat to the dented area. This will weaken the localized area allowing it to move, not affecting the cooler area. This only works on shallow dents, if there are “creases” , its a no – go. If there are creases locking in the dent, the only fix is cutting the tank open and doing hammer and dolly work.

Joe B

August 25, 2023 at 11:10 am #279715

There are any number of videos on You Tube on removing dents

from (motorcycle) gas tanks without cutting them open.

While cutting open a tank can really speed up the process with

time and patience I have learned how to removed most issues from

a tank. After getting a tank as straight as possible using air (above)

I move to the method in the video description box. The process is

ongoing as I’m always trying different things to use as tools but its

really nothing more than everyday automotive bodywork.

https://youtu.be/U5NActQ9LOw?si=M7GCMUck77dCvi3K

Tubs.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

August 25, 2023 at 12:18 pm #279719Tubs, in the video comments, or your info.?, it mentions pulling dents

via slide hammer and hot glue. I’ve seen videos of that on auto body panels,

which would be easier to manipulate than an outboard aluminum gas tank.

If you use the “hot glue” method, I’m sure we’d all be interested in seeing

the tools or procedure that works. Thanks.Prepare to be boarded!

August 25, 2023 at 1:33 pm #279722

There’s not much to it. You glue on what ever your

using and pull. If it comes off and it didn’t move

far enough you glue it back on and pull on it again.

Too far? Knock it back in. The black marker shows

the highs and lows. Just like using a guide coat when

doing bodywork. That what will get you to a flat

surface.

TubsA "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

August 25, 2023 at 6:03 pm #279734Tubs, I’ll have to give the “glue” method a try for pulling dents sometimes.

I’m surprised it even sticks good enough to pull dents.I went to the big city today to look for the 95% (Tin) / 5% (Antimony” solder

as mentioned in the article. The closest I could find was some 95% Tin, and 5%

silver, sold for “Hobbiest and Jewelers”.I tinned the three dent areas on one back corner of the tank, using the

alumi-weld rods, then used a little bottle gas torch to heat of the dents

and melt the solder in. The dents, being on a rounded corner of the tank,

was the first challenge. Filling in a dent on a flat are would have been easier.

It seem like the solder I bought was a little hard to get to flow how I wanted it.

The solder did seem to adhere okay to the pre-tinned areas though, and not

at all to the bare aluminum.

The solder was plenty hard when filing and sanding. I ended up using a sanding

disc in the drill to level it out, then sanding with a board.

The area I repaired kind of looked like a bad Bondo job, except using solder.

Perhaps practice, the correct solder, and more patience would help!The solder I used. I only found some “previously owned” solder on EBay that

had the 5% Antimony. ……. not sure if they make the correct stuff or not,

will have to look some more.“Before photo”

“After photo”

I tried filling in some of the tiny pits on the repair areas, using the same

solder, and my electric soldering gun, with limited success.Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.