Home › Forum › Ask A Member › Am I Running On Only 1 Cylinder? Opinions? ’49 Sea King

- This topic has 33 replies, 8 voices, and was last updated 2 years, 2 months ago by

John Gragg.

-

AuthorPosts

-

October 2, 2023 at 4:47 am #281193

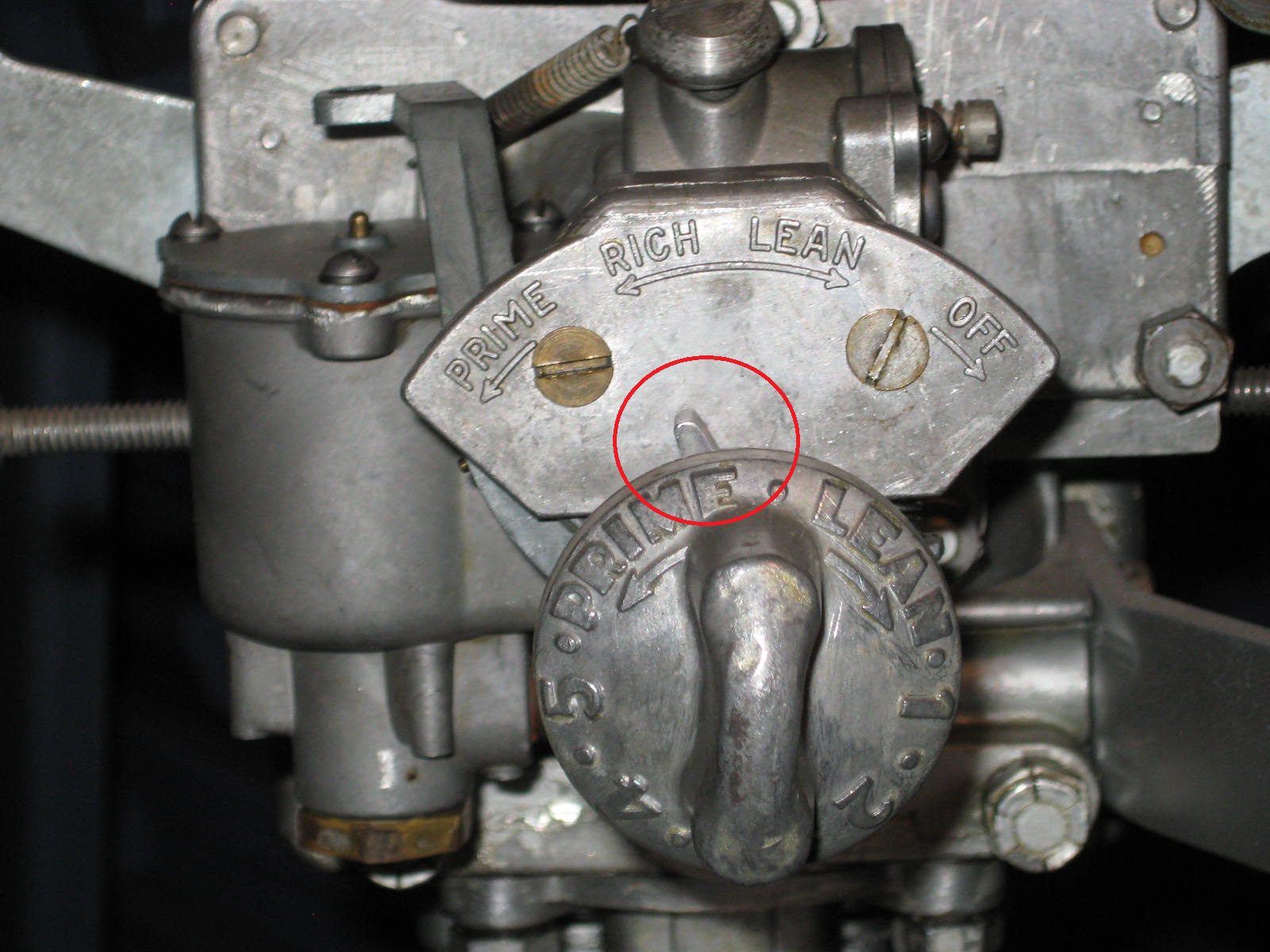

Remember I have NO GAS in my motor so my pictures show my float needle tip down.

Yours will be up and near the primer lever end.

Now your Sea King is running but it is kinda doggy, huffing and puffing. Slowly move your mixture

knob CW until it starts running well. You will need to fine tune this needle position to find your Sea King’s

best running setting. It may take a minute or two and a few tries to get it perfect. This is where you need to

keep your adjusting needle/HS needle still while moving your knob and primer cam positions to where you

want them permanently. Note knob center-line is vertical and primer cam tip is away from the primer lever.

Here is how I set mine:

Sea Kings Baby!!!

October 2, 2023 at 5:00 am #281195Here is how I have my adjustments set for a WARM START. Yes this is a different Sea King from the

other pictures but it has all the parts back on, like I was running at the lake, so that you can see what it

should look like.

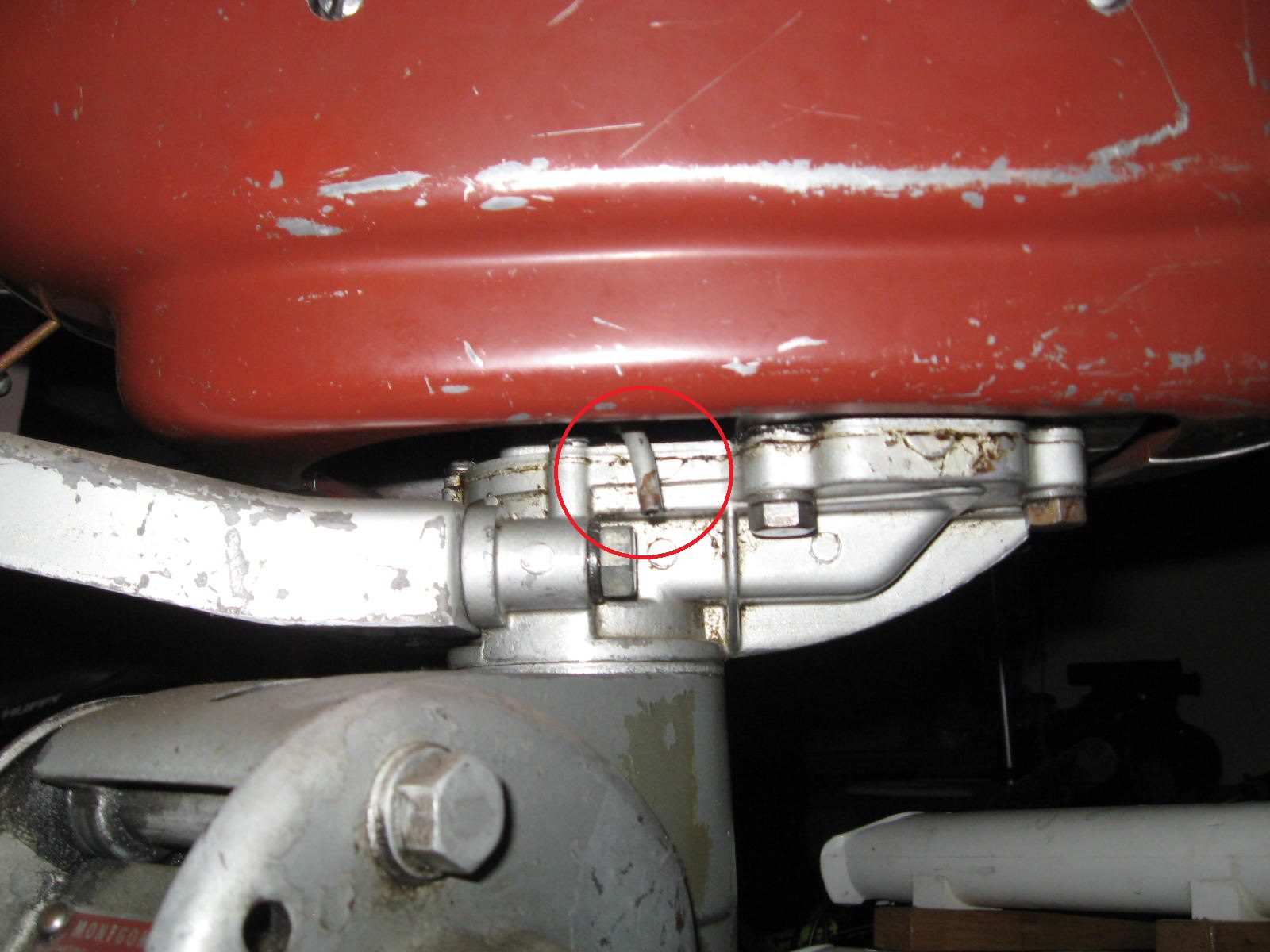

Here is where the water will SPRAY OUT. Not gush. No piss stream. Your Sea King may have only

1 or 2 slats.

Here is the fuel over flow vent tube. When I run on the lake for a week or so I slip on a Tygon hose

that fits into a hole I drilled in a bicycle water bottle. It hangs on the transom clamp.

Sea Kings Baby!!!

October 2, 2023 at 5:12 am #281199Get your Sea King running as well as you can. Then you can determine if you have any intermittent

problems. It is too hard to track down a problem when you make many changes at the same time.

Check your water flow. Check your impeller to see if grease is all over it. Clean it often. The lower

unit usually leaks grease here and there. If left on your impeller it will damage it.

Best of luck.

Sea Kings Baby!!!

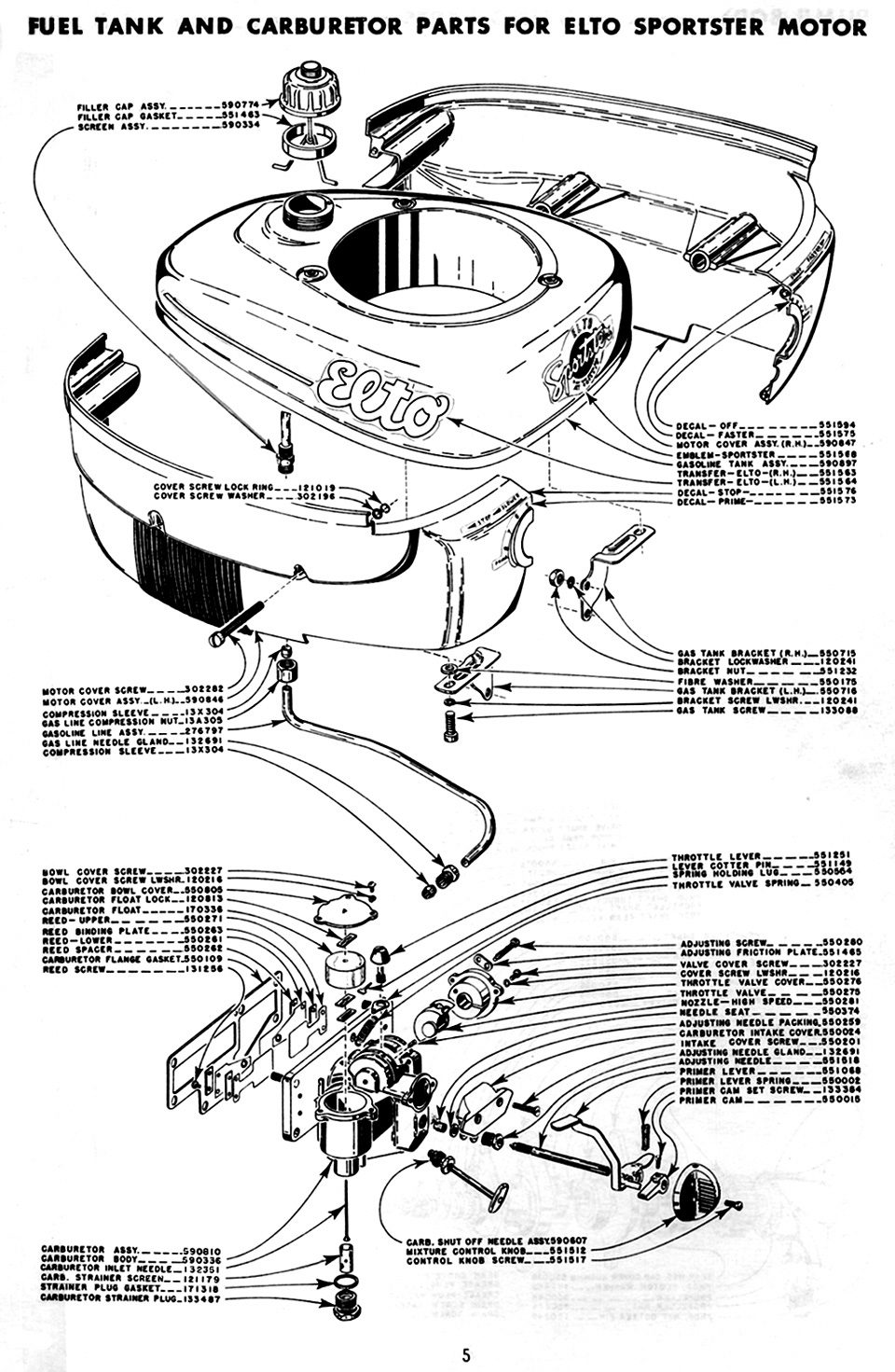

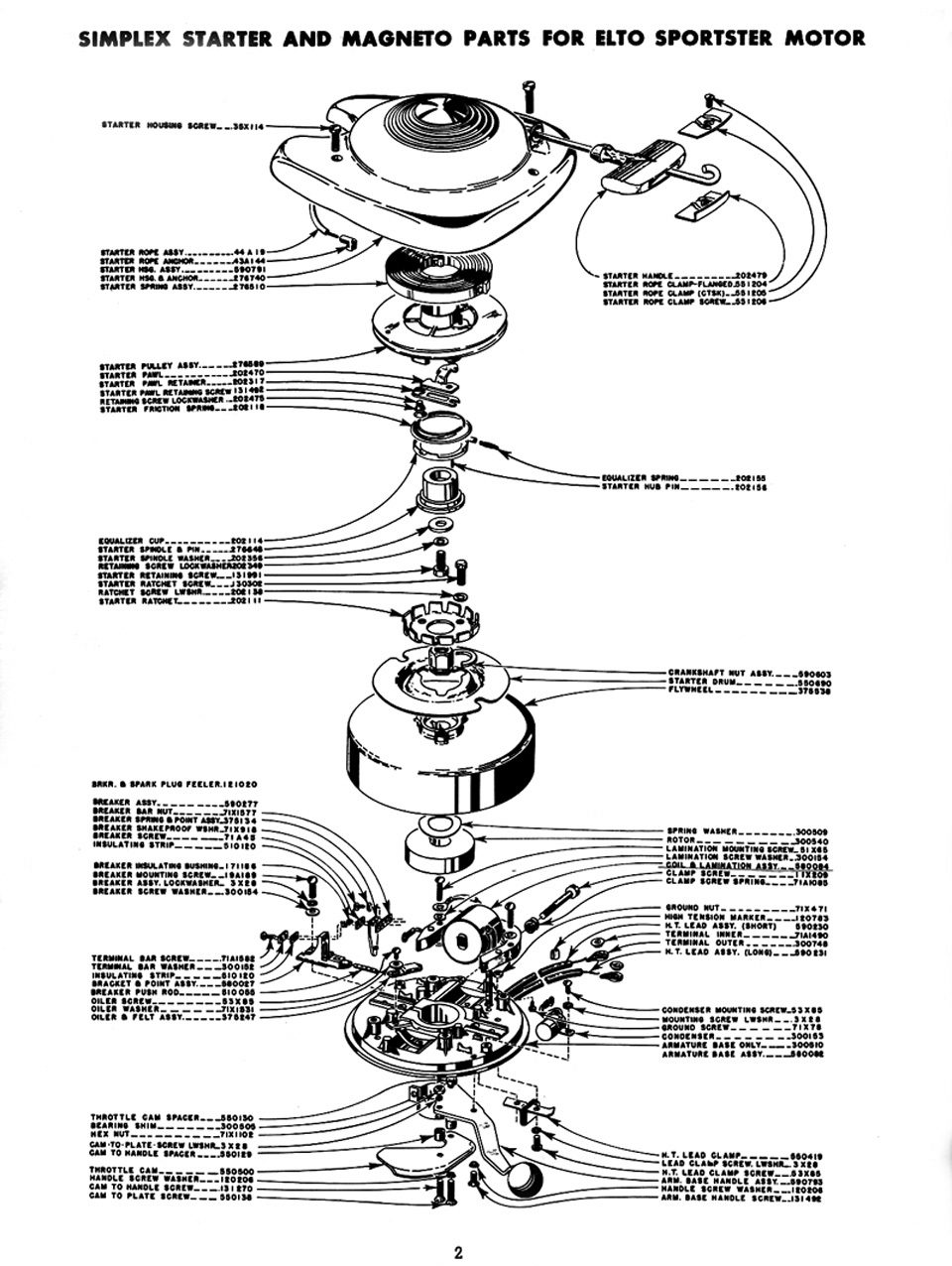

October 2, 2023 at 1:56 pm #281214Here is more info to help you get your Sea King running well.

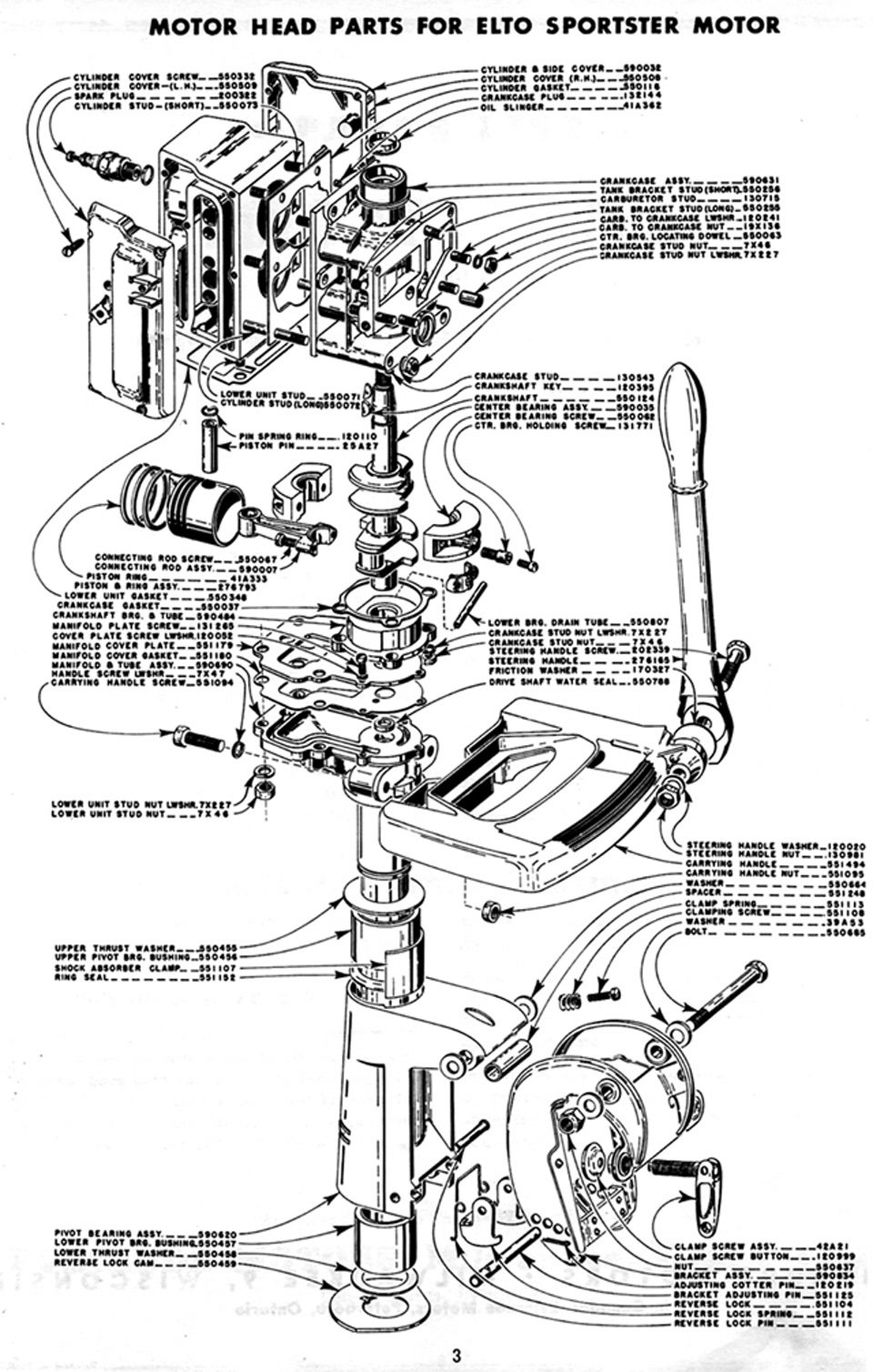

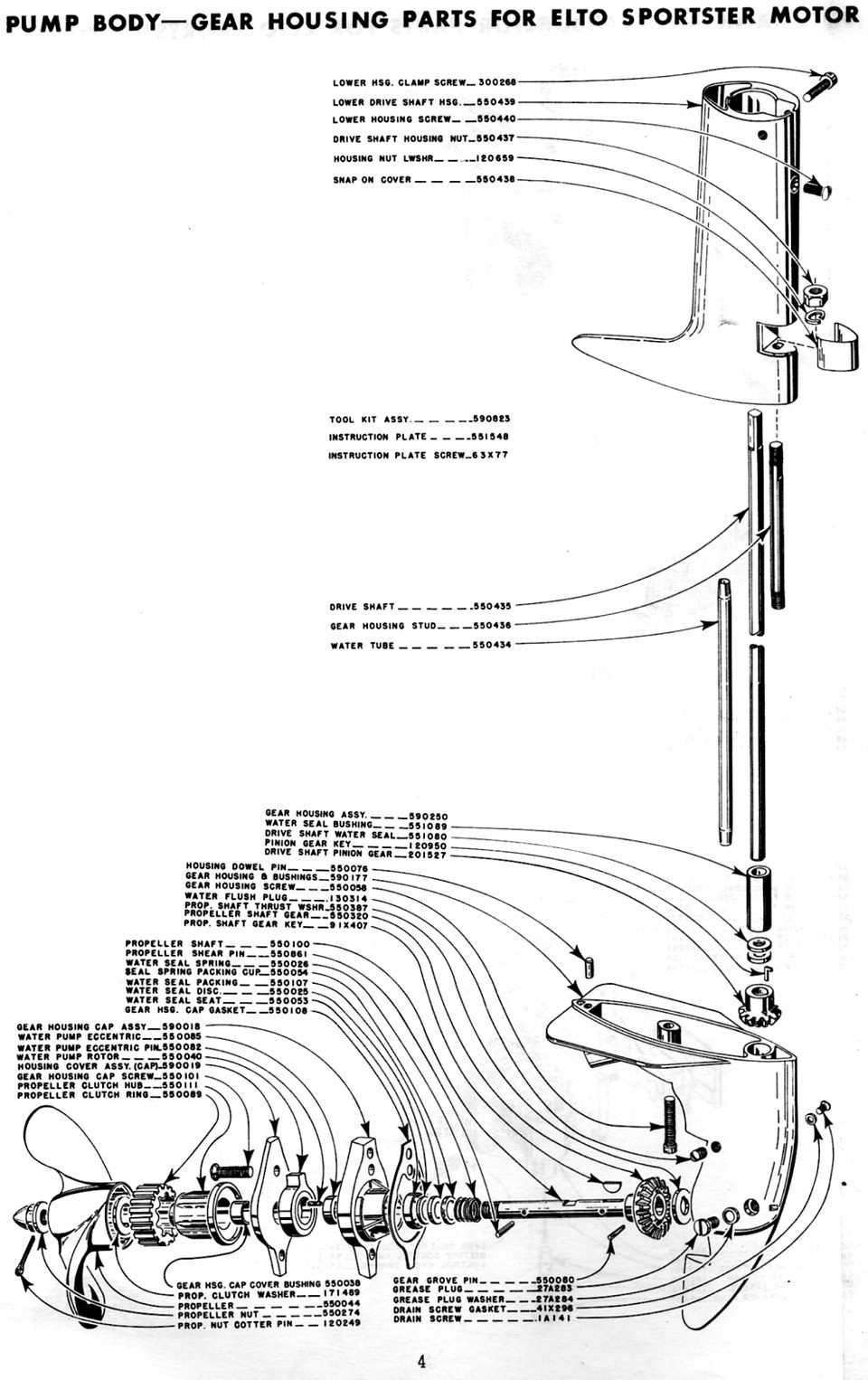

Here is a nice series of diagrams for you to STUDY. Print them out and keep them in your workshop.

Note to yourself where these parts are in the diagrams and on your motor:

Armature base handle assembly aka Throttle lever

Primer lever

Primer cam

Mixture control knob

Adjusting needle aka High speed needle

Thanks, I have many of these, thanks to a few members (Sorry, don’t remember exactly who) and I have a parts manual for the Sea Kings thru ’49. I also found a ‘Service Manual’, if you can call it that. Seems like it is meant more for the dealer pre-delivery person than the dealer mechanic.

I hope I haven’t left you with the idea that I’m lost here? I admit I’m new to this hobby, which I love so far. Keeps me active on a daily basis and in the garage busy. I’m not ancient, but a few of my meds fog me up a little when it comes to some basic stuff.

I’m no stranger to internal combustion motors, see below. Circa 1981? 68 Firebird 400. I’m learning 2 strokes and because of the unknown history of the motors I’m questioning everything not knowing if it’s going to run or not.

Anyway, yes I’m making mistakes. And I appreciate your input and advice. I don’t think I need to STUDY any diagrams, since I’ve used these (similar, not exact) for more hours than I care to admit. I will say I wish I knew the Elto was another version of the Sea King, I’ve seen many posts here regarding Eltos owned by members but never put them into the same basket as the Sea King and others.

Again, thank you for the added information. The exploded views of the motor are far better than what Sea King/Monkey Wards manuals show.

I spent some time at Ace Hdwr yesterday, and I’m headed out to the garage to get things tightened up a bit. Hopefully I will have some positive results to report later.

Thank you again,

Best Regards

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 2, 2023 at 2:23 pm #281220Wow! Thank you very much. I was answering the posts here 1 by 1, so I had no idea they were all from you. Much appreciated.

All great information. I’ve read a lot, and yes I knew that the hs needle is where the adjustments were to be made. In the video I was just feathering the throttle a little to hear how it sounded, hoping I could determine if it was on 1 hole or 2. It was my last start for the day, so I was fully ready for it to quit. I had shut off the fuel petcock I installed to run the carb dry.

I was pointing to the crankcase drain thinking it was the pee tell. My 17 year old nephew was recording and I was telling myself and him that we weren’t peeing, so the day was over for the time being until I was sure I wasn’t going to grenade the motor.

What are you using for a float? I made a coke float that worked for a day, but swelled just a bit so I had to ditch it and put in a sierra 18-7208. I thing Frank or Bucaneer talked about it.

Again, great information. Thank you!

Keep in touch

Best Regards

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 2, 2023 at 2:28 pm #281221P.S.

Excellent idea for the fuel recovery. I read an article someone posted here talking about how they recover a TON of fuel/oil mix from their crankcase.

This reminds me, I need to go clean the driveway…when I dumped the trash can the other day it had some oil drops that left stains on the concrete. Wifey don’t like that.

Thanks!

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 2, 2023 at 3:01 pm #281223Remember I have NO GAS in my motor so my pictures show my float needle tip down.

Yours will be up and near the primer lever end.

Now your Sea King is running but it is kinda doggy, huffing and puffing. Slowly move your mixture

knob CW until it starts running well. You will need to fine tune this needle position to find your Sea King’s

best running setting. It may take a minute or two and a few tries to get it perfect. This is where you need to

keep your adjusting needle/HS needle still while moving your knob and primer cam positions to where you

want them permanently. Note knob center-line is vertical and primer cam tip is away from the primer lever.

Here is how I set mine:

So the pic showing the closeup of the hs knob…that is with the hs needle set at the approx 1/2 way open setting, then adjust for best tune once warm and reset knob and cam to same relationship?

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 2, 2023 at 4:54 pm #281226I am really surprised that it runs at all with the flywheel removed. The weight of the flywheel supplies the momentum needed to keep it rotating between compression strokes,

You better hope you don’t see any water coming out of that curved tube. That tube is the crankcase puddle drain. It drains off any excess fuel that may collect in the crankcase. Water in the crankcase would be a bad thing.

There is no telltale as such. Water pump working indicator is water droplets blowing out the exhaust relief slots or holes about half way down the backside if the leg.

Frank,

You are soooooo right. I had no idea. I’m completely confident I will be able to start the motor with the pull starter now. Before, I could not imagine how this motor would start that way, it took so many revolutions with the drill…

Thanks!

Best Regards,

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 2, 2023 at 5:27 pm #281227Remember I have NO GAS in my motor so my pictures show my float needle tip down.

Yours will be up and near the primer lever end.

Now your Sea King is running but it is kinda doggy, huffing and puffing. Slowly move your mixture

knob CW until it starts running well. You will need to fine tune this needle position to find your Sea King’s

best running setting. It may take a minute or two and a few tries to get it perfect. This is where you need to

keep your adjusting needle/HS needle still while moving your knob and primer cam positions to where you

want them permanently. Note knob center-line is vertical and primer cam tip is away from the primer lever.

Here is how I set mine:

So the pic showing the closeup of the hs knob…that is with the hs needle set at the approx 1/2 way open setting, then adjust for best tune once warm and reset knob and cam to same relationship?

The picture above is my warm engine running perfectly mixture knob setting. The red circle highlights

the position of the primer cam tip. It is “up and out of the way” of the primer lever. You can not have it

so close to or dragging on the primer lever. It will cause a flooding condition. This is why you need to

study the diagrams. You have to understand the relationships of these moving parts. Your settings do

not have to be exactly like mine. The picture also is my warm start setting.

The “1/2 to 3/4” or “3/4 to 1” number is an arbitrary number. It is used to get you in the ball park

for starting out only. When you disassemble something for cleaning or repair you need a “starting point”

don’t you? Well “that number” is it!!! Once you get your Sea King running perfectly “that number” may

be 5/8, 1 or 2/3. It does not matter what it is. It is your number. It will not be exactly right for one of my

Sea Kings. Now when you find “your number” you will need to adjust the primer cam and mixture control

knob’s orientation so that it works properly together. You can set them any way you want visually as long

as the assembly works correctly.

I’m showing you how I do things for simplicity and ease of operation. Best of luck.

Sea Kings Baby!!!

1 user thanked author for this post.

October 2, 2023 at 5:36 pm #281228The pics are for DBKSKI – Safety First! LOL!!!

Video link at the bottom…

Simply Amazing!

So I put it all together, (for the most part) except I did forget to add the starter ratchet and nuts to the top of the flywheel/starter drum. I guess I’m lucky the starter drum didn’t fly off and bean me! (Just saying it for the record before someone calls me out on it.)

So here is 16 seconds of the motor running, out of about 52 seconds it ran before I fussed with the HS knob enough that it quit. As you can hear on the video, it surges as little and I’m a little concerned that I have a vacuum leak? The packing on the HS needle is ‘iffy’ at best, so maybe I’m leaking air there? I did exactly what dbkski said in terms of how to make the adjustments but nothing seemed to work. Not sure if I needed to wait longer in between adjustments, or what? I did make sure I was waiting at least 3 or 4 seconds between needle movements, but like I said it’s almost like the HS needle was not even connected…

After several starts and attempts to get it running as ‘perfect’ as possible, I ran into another issue. It would Start, Run, Rev High (without any user inputs) and quit. All this would take about 5 to 7 seconds. I finally got smart and got eye level with the carb and noticed that the float needle was bottoming out when it quit. I would watch and the needle would slowly rise, I would restart it and the same symptoms would reappear, exactly as before.

My guess?:

Somehow my issue is tied to the float, I just can’t figure out how. The motor stalls out when the float needle bottoms out. With the needle in that position, I should have fuel entering the bowl, but I don’t (at least not quickly enough). So I have a fuel delivery problem?

I have the Sierra 18-7208 float in there in place of the original cork float (which was trash) but I could not figure out a way to suspend it on the float needle properly so I think it might be slipping.

I have seen where (I think it was Buccaneer or Frankr) someone was discussing using the 7208 float (with modifications). Can anyone tell me what those mods are? I’m guessing etching/cutting a groove 1″ from the top of the float needle to serve as the top limit stop for the float and another at the bottom of the float height? What would you use to cut those grooves? First thing that comes to mind is a copper pipe cutter, set into position and carefully used to make the groove? Better ideas?

In the meantime…I’m going to fashion another cork float and I have ordered another Sierra float to try to get that part of this solved. The great news…. It RUNS! It is running on BOTH cylinders. The impeller is doing its job keeping things cool!

https://youtube.com/shorts/0IWOesJpSfs?feature=share

Best Regards,

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19 -

AuthorPosts

- You must be logged in to reply to this topic.