Home › Forum › Ask A Member › Am I Running On Only 1 Cylinder? Opinions? ’49 Sea King

- This topic has 33 replies, 8 voices, and was last updated 2 years, 2 months ago by

John Gragg.

-

AuthorPosts

-

October 2, 2023 at 7:58 pm #281235

Great. You have made some improvements. You need to adjust the HS needle at full throttle.

Not at less than 1/2 throttle where the video is showing the motor running. Your carb needle’s

tip should be up pretty far above the cap. I don’t know the dimension off the top of my head but

if your’s is only an 1/8″ to 1/4″ of an inch or so then that is not correct. The bowl is not full.

Now get rid of that fuel line abortion that you have. Use 1 piece copper or aluminum tubing

with the correct fittings. If you like rubber fuel line with an inline filter then you need different fittings.

Don’t mix them. A fuel filter is a good idea but not the way you have it now. You don’t need two.

Did you clean the fuel tank? Did you look for the tiny filter in the tank? Is it in good working condition?

Yes there are clips on the carb bowl needle. I use cork floats sealed with the Aero Gloss Dope. The sierra

plastic float is great if you set it up properly. Did you? How is your needle attached to the float?

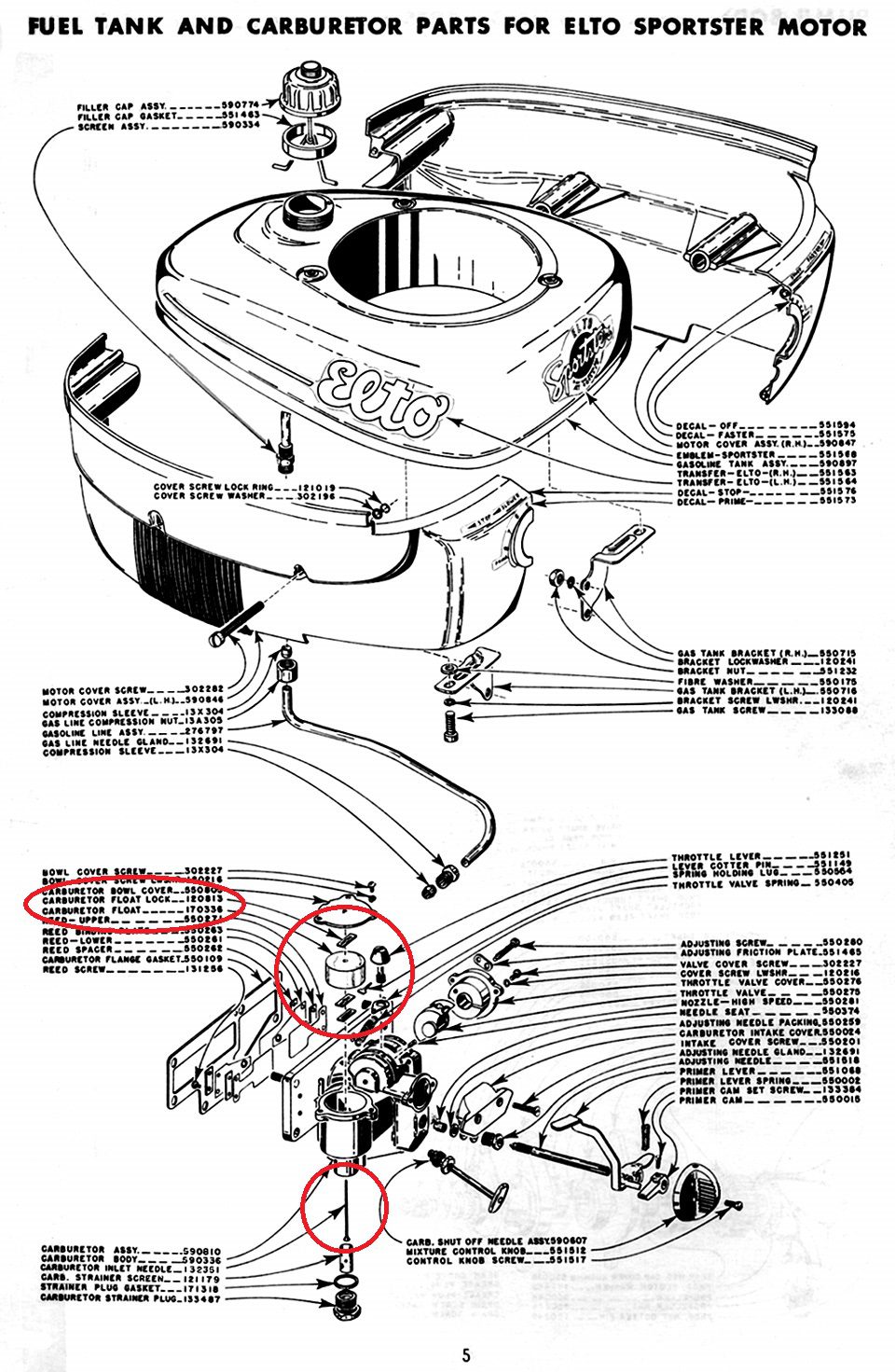

Do not run your fuel line with “uphill” bends. It won’t work properly when you are low on fuel. Here is a

picture of fittings for the fuel line or fuel tank.

Sea Kings Baby!!!

October 2, 2023 at 9:34 pm #281244Great. You have made some improvements. You need to adjust the HS needle at full throttle.

Not at less than 1/2 throttle where the video is showing the motor running. Your carb needle’s

tip should be up pretty far above the cap. I don’t know the dimension off the top of my head but

if your’s is only an 1/8″ to 1/4″ of an inch or so then that is not correct. The bowl is not full.

Now get rid of that fuel line abortion that you have. Use 1 piece copper or aluminum tubing

with the correct fittings. If you like rubber fuel line with an inline filter then you need different fittings.

Don’t mix them. A fuel filter is a good idea but not the way you have it now. You don’t need two.

Did you clean the fuel tank? Did you look for the tiny filter in the tank? Is it in good working condition?

Yes there are clips on the carb bowl needle. I use cork floats sealed with the Aero Gloss Dope. The sierra

plastic float is great if you set it up properly. Did you? How is your needle attached to the float?

Do not run your fuel line with “uphill” bends. It won’t work properly when you are low on fuel. Here is a

picture of fittings for the fuel line or fuel tank.

Yes, I’m aware of the issue with the float needle being too low. That’s why I’m starved for fuel. It was fine for awhile, but after a few tries it stopped working properly. I thought maybe the fuel was low in the tank and not supplying the carb bowl, so I even added a little to the tank. I was intentionally running it low so if I had to remove it I wasn’t draining/dripping a ton of fuel all over everything.

To answer your questions directly…

“You need to adjust the HS needle at full throttle.

Not at less than 1/2 throttle where the video is showing the motor running.”

Yes, but I was unable to get the motor running at full throttle. I would give it advance but it acted like I wasn’t doing anything. Played with it a little, no changes to speak of so I did my best with where I was.

“Your carb needle’s tip should be up pretty far above the cap. I don’t know the dimension off the top of my head but

if your’s is only an 1/8″ to 1/4″ of an inch or so then that is not correct. The bowl is not full.”

I understand that. I am fully aware of what the needle looks like when the bowl is full. It was working, then it stopped.

“Now get rid of that fuel line abortion that you have. Use 1 piece copper or aluminum tubing

with the correct fittings. If you like rubber fuel line with an inline filter then you need different fittings.”

If you can point me to where to get the fitting for the carb inlet (gas line needle gland, part number 132691) then please do. I have searched the world and ended up robbing one from the fuel shutoff from another carb I bought for parts. I’ve checked McMaster Carr, etc, etc. They entire brass pipe/fittings are available on EBay, but most of the sellers are jacking the prices to unbelievable heights. More info on this “abortion” below…

Bottom line on this question…I would love a website where I can buy the male needle gland fitting!!!!!! I will be amazed if you can show me one.

“Don’t mix them. A fuel filter is a good idea but not the way you have it now. You don’t need two.”

I don’t have two. The original that usually sits in the tank is not in there. I could not find a FIP to FIP (1/8) anywhere (I wanted and needed a petcock), so I started with the petcock and worked down from there. It is TEMPORARY only, just to see where I stood on if the motor was going to run or not.

I do have the original fuel line and tank fitting. Again, the ABORTION was TEMPORARY while I ensured the tank was clean, the motor would run, etc.

“Did you clean the fuel tank?”

Um, DUH! Only about 10 times. It was pure, hardened lacquer. I soaked it in denatured alcohol for 3 days, rinsed and did it again. Followed up with a fuel tank cleaner I got from Autozone. I then opened up about 15 dove load shotgun shells and loaded them and more fuel tank cleaner into the tank and shook it like the dickens. Up, down, sideways, you name it! I still ended up getting some sludge in the carb bowl screen, but eventually everything cleaned up.

“Did you look for the tiny filter in the tank? Is it in good working condition?”

I think you are talking about the screen at the top of the fuel fitting that goes into the tank. If so, yes, I cleaned it and have it ready to install.

“Yes there are clips on the carb bowl needle. I use cork floats sealed with the Aero Gloss Dope.”

I know about the clips, that’s why I mentioned them. I’ve had my share of carbs apart. Where can I get some Dope? I’m in California, EPA does not allow most of that stuff anywhere in CA and you can’t even ship it in. I’ve searched the internet and cannot find any that is not 20 years old and 20 times the price it should be.

“The sierra plastic float is great if you set it up properly. Did you? How is your needle attached to the float?”

I don’t know how to set up the plastic float properly, that is why I ASKED up above how to do so. I didn’t want to ruin anything, so for now all I did was make the hole at the top of the float barely big enough (3/32″?) for the float needle to fit through then hoped that the interference fit would do the job and hold it in place. Obviously that is not the case, since the float stopped doing its job.

If you read my post, even though I had initial success, it was short-lived as the float bowl started emptying very quickly and the motor would starve for fuel and die. I watched the needle rise, then started it again. Same symptoms, every time. Not sure why.

“Do not run your fuel line with “uphill” bends. It won’t work properly when you are low on fuel. Here is a picture of fittings for the fuel line or fuel tank.”

Yes, I’m aware that this is a gravity fed carburetor. I already have the fitting on the right.

Can you help with:

1.) I’m making floats tomorrow. Where can I get some Dope?

2.) What is the BEST way to attach the plastic floats to the needle?

3.) If I can’t get dope, I’m going to run without it. Tubs has a 2 or 3 year experiment showing the floats continue to “FLOAT” for 3 years sitting in fuel/oil mix. Your thoughts?

4.) What do you use for packing for the HS needle?

5.) Is it possible I have a vacuum leak and that is why I’m surging?

Thanks again,

Best Regards,

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 2, 2023 at 9:36 pm #281245P.S.

Tomorrow I will send the last few seconds of the video. That is where I try to advance the throttle and the motor dies. Did it several times.

Thanks,

Best Regards,

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 3, 2023 at 5:00 am #2812531.) I will check my place for the Aero Gloss tomorrow. I may have a fuel line compression gland.

2.) With the same clips that the cork float used. Did you sand the cone off the Sierra float and try

to match the length to the cork one? There are grooves in the needle to be used for the clips. They

line up to where the bottom and top of the float contact the needle.

3.) A nice new cork float will work just fine for testing.

4.) You can buy the proper packing from the same place you got the Sierra float. I use thick o-rings.

Take your HS needle to the hardware store and match them up. Remember the thicker o-rings work

better. I put 3 or 4 of them on the needle then screw it in. The tension nut will compress the o-rings.

Yes that could be your problem. If it is loose that is no good. It will leak.

5.) Anything is possible. You have identified problems but still decided to test run anyway? Guess what?

Those problems are probably why your Sea King is running crappy. Fix the known problems. Then test,

test, test!!!

Sea Kings Baby!!!

October 3, 2023 at 8:38 am #281257Since this thread is tending to be a general primer on this motor, I’ll jump in with an ignition question. There was a suggestion to check for cylinder firing by leaving one plug wire off. My understanding is that this is never a good idea, because a spark plug wire not to a plug or grounded will damage the ignition coil. That said, I see from the parts diagram that this motor has only one ignition coil and yet is an alternating firing twin ( I believe) . So, how does that work, absent some kind of distributor arrangement? Or perhaps this is a “wasted spark” system. Any thoughts on this?

One way to check if it’s firing on both cylinders is to run the motor for a few minutes and feel the spark plug body, if hot it’s firing, if cool that cylinder is dead.

Joe B

October 3, 2023 at 9:18 am #281258There are two coils alternate firing

October 3, 2023 at 1:50 pm #2812851.) I will check my place for the Aero Gloss tomorrow. I may have a fuel line compression gland.

2.) With the same clips that the cork float used. Did you sand the cone off the Sierra float and try

to match the length to the cork one? There are grooves in the needle to be used for the clips. They

line up to where the bottom and top of the float contact the needle.

3.) A nice new cork float will work just fine for testing.

4.) You can buy the proper packing from the same place you got the Sierra float. I use thick o-rings.

Take your HS needle to the hardware store and match them up. Remember the thicker o-rings work

better. I put 3 or 4 of them on the needle then screw it in. The tension nut will compress the o-rings.

Yes that could be your problem. If it is loose that is no good. It will leak.

5.) Anything is possible. You have identified problems but still decided to test run anyway? Guess what?

Those problems are probably why your Sea King is running crappy. Fix the known problems. Then test,

test, test!!!

Are you saying the Sierra float has enough meat in the cone to allow me to sand it down to the same height as the original cork float?

If so, easy peesy.

If not, I’m making new cork floats today. No biggie…

Funny thing about ‘known problems’, you don’t know you have them until you ‘test’, right? I did not know anything, and still don’t, regarding a vacuum leak. Until I resolve my float problem I won’t know anything for sure.

Also, prior to testing I changed the HS needle to the one that will accept the removable knob. So that is another variable in the equation.

I have already tried o-rings, but ended up with a needle that would not move. I just bought an assortment that I will pick from and see if I can come up with a combination that works.

Did you note the size and quantity of o-rings you used for yours? That would be helpful information.

Thanks,

Best Regards,

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 3, 2023 at 8:36 pm #281295Update:

I know I can be wordy in these posts, my apologies. I will try to keep this on the short side without missing important information.

I honestly did not know the Sierra 7208 float was solid. I didn’t hear back from Dbkski before I made it to the garage, so since I already had another on order I marked the appropriate height to mimic the size of the original float and cut the dome off. From there it was easy. Mounted the float to the float pin with the keepers and closed her up.

I ditched the temporary fuel line I had set up and put my hard-line back in. Trouble is those ferrules don’t last forever so it finally started leaking. No worries, I got smart and googled the part # for the ‘gland’ as they call it in the parts guide. I found a few so I bought a used one and 2 brand new ones. I already bought the 1/4″ copper, so once I get the new gland I can make myself a new hard line.

Next, I did replace an o-ring on the HS needle that I thought might be a little iffy. I put a slightly thicker one on, although I don’t think it was really an issue.

Between the hard line, the float and (maybe) the o-ring she runs pretty well now. The link below is 5 minutes, but I explain what I did and show the motor running through the full power band. She idles much better and really only has trouble with running maybe a little rich at about 1/3 throttle (about the starting spot).

I will be posting a 2nd video (9 seconds) showing bubbles coming from below the power head right around where I expect the driveshaft would be? Maybe someone has an idea what that is? I guess I’ll start a separate thread for that.

Thanks again to everyone who contributed to getting this beast running this well.

Now I’m going to spend some time cleaning it up, maybe a coat of paint here and there. Thoughts?

Leave it, or paint it (semi-restore)?

Thanks again everyone!

https://youtu.be/HA9Ec_6IUUg?list=PL4HXqWe5ea9jL0lj2Epr8vb6yI4cnjXOO

Best Regards,

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19October 3, 2023 at 11:28 pm #281302Great job! Persistence pay’s off. Sounds like it’s ready for

the boat!Prepare to be boarded!

1 user thanked author for this post.

October 4, 2023 at 1:37 am #281310Great job! Persistence pay’s off. Sounds like it’s ready for

the boat!I wish.. I’m in wonderful California where 2 strokes this old are banned on our waterways.

No worries, I’m doing this purely for the love of “old stuff”, old outboards being at the top of my old stuff list. 60s muscle cars are right there as well.

On to degreasing, cleaning and perhaps a little paint.

Concurrently working on the TD20, also a ’49.

Thank you for all your helpful advice Bucaneer!

Best Regards,

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A. Sold

49 Sea King 5hp GG9014A

48 Johnson TD20. Sold

49 Johnson TD20. Sold

54 Johnson QD15. Sold

55 Johnson CD12. Sold

57 Johnson RJE-19M

57 Johnson RDE-19 -

AuthorPosts

- You must be logged in to reply to this topic.