Home › Forum › Ask A Member › Anodes on Evinrude 18 hp 1960

- This topic has 28 replies, 9 voices, and was last updated 2 years, 6 months ago by

salnaes.

salnaes.

-

AuthorPosts

-

October 24, 2022 at 10:11 am #268179

The proper terminology is anti ventilation plate as it helps to prevent the prop from ventilating to the atmosphere, or sucking in air. Cavitation is something totally different and can happen to a submarines prop several hundred feet below the surface if it spins too fast. Somewhere in time anti cavitation got applied to it and it seems to have stuck and that is what most people refer to it as.

This is really interesting Mumbles. If salnaes hadn’t questioned your spelling

would I have gotten to learn this? Frank stated “Ole Evinrude called it a cavitation

plate”. Seems the Johnson brothers did as well.

Some time ago I read that calling the brass sleeve in a compression fitting a ferrule

is not correct. I don’t remember exactly what name was used. I wouldn’t be surprised

if someone here has that answer as well.

Tubs.

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

October 24, 2022 at 12:18 pm #268188Hey Tubbs, I’ve always referred to that compression fitting part as a ferrule but my parts man calls them a sleeve and I’ve heard of them being referred to as a compression ring to. I think sleeve is the correct terminology as the dictionary describes a ferrule more as something which is used for reinforcement. Guess I better change my ways and ask for a sleeve next time I’m in my auto supply so I sound like I know what I’m talking about! Thanks for bringing that up!

Salnaes: Drilling holes in the AV plate might be a big uff da as the salt will find its way under the paint and cause corrosion on the aluminum plate. It’s really hard to prevent that from happening no matter what kind of primer is applied to the freshly exposed aluminum. You might want to reconsider installing an anode, especially if the motor and paint are in nice condition. Better yet, it might be best to use a disposable motor in the ocean, such as a four stroke Yamaha or Merc.

Norway eh? One side of my family came from there over 100 years ago and are mostly grain farmers on the Canadian prairies now. The Viking blood flowing in my veins is probably why I naturally enjoy boats and being on the water so much!

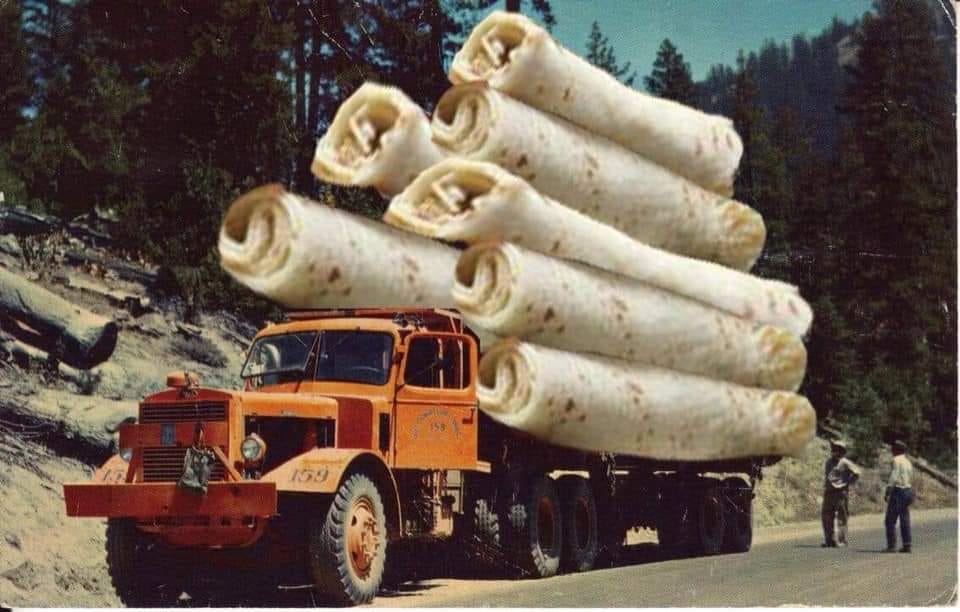

This years garden potatoes have been dug up and are now ready for making lefse, West Coast style lefse!

October 24, 2022 at 12:51 pm #268192

October 24, 2022 at 12:51 pm #268192Nice to get to know new folks. The world ain’t that big. I’v been awake for 12 hours now, and the evening is still young here. The sun is probably on it’s highest by you soon. Here it’s disappeared for some hours now.

We eat lefse all over the country, but not that much by my place, the south-eastern Norway. We have butter , sugar and cinnamon on it. If you did not try it, you should pay us a visit. 🙂 I have relatives in Seattle, and they’ve been here.

Right now I’m going to the cinema with some friends. I might drop by aomci after midnight and ask you guys another question, since I can’t use a torque wrench and socket wrench because hex screws are positioned so that the socket wrench can’t be put on the screw. That’s really bad. So I don’t know what to do. Luckily I discovered this before I put Loctite 518 on the flange on the crankcase. Puh.

October 24, 2022 at 1:12 pm #268193Hey Mumbles. You’re right. Based on what you have told me I’ve decided not to install anode on my Evinrude. After all it’s an old outboard and I won’t use it much. Only occasionally trips in salt water.

I’m not going to use this old boat and outboard for recreation purposes. I have another modern boat with Yamaha for that. I’m restoring the old boat and engine just because I want to take care of some history that the young people have not experienced in their lives. I want to show how it was in my youth.

Now I have to go to the movie. See you later.

October 24, 2022 at 3:42 pm #268194I wouldn’t use anti-seize of any kind on a powerhead as it usually gets all over everything and isn’t really neccesary. Once I used aluminum bases ant-seize on a Chrysler 55 I had years ago and it caused more problems than it solved. After using the motor in the salt, there was some kind of reaction and the bolts holding the gearcase on were harder to remove than they were originally. Lesson learned.

For sealing the crankcase halves, I like to use Permatex Anaerobic Flange Sealer or Gasket Maker. Both surfaces need to be super clean and it only sets up once the pieces are bolted together. There is a copper based primer which can be also used with it to to help it set up. Others prefer the old school 3M 847 but it might contain fillers and is harder to work with as it is like wet and runny snot. The parts also have to be assembled immiediately after applying before it skins over. With anaerobic sealers, you can go and have lunch after applying it and then assemble the parts when you come back.

October 24, 2022 at 8:04 pm #268221

Mumbles,The term wasn’t common. It was

a word I had never hear before. I suspect

it was brought up on this board but some

time ago. Tubs.A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

October 25, 2022 at 4:46 pm #268261I’m not an expert, so I’ve been spending hundreds of hours on the Internet searching days and nights to learn how to rebuild my Evinrude from 1960 and find parts, tools and accessories. Finally I discovered aomci.org and decided to sign up and pay for membership as International member since I live outside America. It was the best investment so far, joining this website.

Finally I got in touch with experienced people who could help me make the right decisions and give answers to difficult tech questions that arises all the time during restoration. Thank you all for sharing knowledge.

I have been investigating all possible sources to make the right decisions on different matters concerning my outboard, and based on what I read and watch I have to make a choice like should I use this sealer or the other or no sealer.

That’s only one example.

Brandons Garage on Youtube seems like a good source. So do folks at aomci.org. Since there are different point of views on different matters, I finally have to decide myself. What is best? What shall I do?

Where did Brandon learn to put anti seize on the threads on crankcase bolts? Did he have any previously experience with this before he made his video? Mumbles advice against using anti seize on the power head. He had bad experience with it.

May be the trouble was caused by to much lubricant on the bolts?

Loctite 8150 Aluminiumm Anti Seize is designed to put on threads on bolts in extreme high temperatures. The Technical Data Sheet instruct us to put just a small amount on the threads.

LB 8150™ is an anti-seize lubricant to protect threaded connections exposed to high temperatures up to 900 °C to prevent seizing and corrosion.

Directions for use

Apply to clean parts which need lubricating, avoid excessive lubrication.

This product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a lubricant for chlorine or other strong oxidizing materials.May be this product will cause problems if there is to much Anti Seize on the bolts. It’s not recommended for use in contact with oxygen, so my guess is that the product will be fine if one just put a small amount on the threads only, and make sure it’s so little that it’s not being squeezed out of the hole when tightening the bolts. If all the lubricant stays inside the threaded hole after the bolt is tightened, it will not be exposed to oxygen. That’s my guess. But I’m a novice and not sure.

When I saw Brandons video he put much lubricant on the bolts, much more than needed to fill the threading. Did he get trouble? He will probably find out the next time he disassembles the power head.

I feel like following Mumbles advice, but I’m still thinking. Any thoughts are welcome.

October 25, 2022 at 7:00 pm #268270I think it is the copper content in the anticize that has a bad reaction with the aluminum

October 25, 2022 at 7:50 pm #268271Back by in my Volkswagen days we used Permatex aviation form a gasket to mate the engine cases together. Never had any issues.

October 25, 2022 at 8:05 pm #268274I never use anti-sieze compound in any of my outboard restorations. As Mumbles said, it makes a big mess and as Dave noted, many anti-sieze products contain copper which can have a bad reaction with the outboard’s aluminum, also making the bolts harder to remove in the future. A company called Jet-Lube makes a marine grade anti-sieze product that supposedly does not contain any metal compounds but I’ve never tried it. If a bolt or gasket may be in contact with water, I typically use the Permatex Aviation #3 gasket sealer. So for me, it goes on the crankcase bolt threads, cylinder head bolt threads, on the exhaust cover gaskets and on the powerhead base gasket where it attaches to the exhaust section. Here where I live with warm salt water, local marine mechanics use a waterproof grease on these same bolts or a Teflon based pipe thread sealant. There are a lot of folks here at AOMCI more knowledgeable than me, but I am only sharing what has worked well for me.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings." -

AuthorPosts

- You must be logged in to reply to this topic.