Home › Forum › Ask A Member › Backfire/misfire thru carb

- This topic has 105 replies, 9 voices, and was last updated 1 year, 7 months ago by

Beno.

Beno.

-

AuthorPosts

-

August 29, 2020 at 6:52 pm #213047

OK well that little hole in the thermostat plate is a programmed bleed by, but it you look closely at the thermostats you will see a tiny “V” notch right in the top of the brass thermostat caps that allows a little bit of water to pass through even when thermostats are closed. Those two springs and plastic valves allow the higher pressure cooling water achieved at higher RPMS to push those relief valves open and let more cooling water through. So, oftentimes, engine temp comes down a bit at higher RPMs because more water is traveling through the powerhead due to the open relief valves. If anything, vents right at the top of the cylinder water jackets would be the best way to allow trapped air to escape.

In any event, that thermostat housing looks perfectly clean, so we must look farther down the line in the adapter housing to see what is plugged up. Like I say, not that familiar with the turbojet set up, but I am confident you can locate where the engine cooling water exits the adapter. I guess I would be inclined to blow backwards from the adapter cooling water exit with compressed air or high pressure water to free up whatever is plugged up. I can’t remember where that crazy exhaust elbow is located, is it on the adapter housing? If so, you may have to remove it to find whatever is plugging up the system…Disregard this if the exhaust elbow does not mount to the adapter housing….August 29, 2020 at 8:33 pm #213061I will keep investigating soon, taking tonite off as the hurricane rain remnants pass thru.

I have ordered parts as follows to reassemble.

Today i took the mounting exhaust plate to get tig welded. Seems like a nice fella, decent setup, we assertained the previous welding attempt someone else made had gone horribly badly.

Thats me with the frown waiting for him to get setup to weld.

Here we are grinding the crack out to get proper penetration.

August 29, 2020 at 8:41 pm #213067

August 29, 2020 at 8:41 pm #213067$60 and I was off and on my way

August 30, 2020 at 7:31 am #213107That man is an artist for sure, what a beautiful job! I just paid $65 to weld up a 6hp shift handle, and it looks like crap….Guess that is not totally fair, there wasn’t much meat to work with on the shift handle.

Sounds like you have removed the exhaust elbow, did you find the cooling obstruction?September 1, 2020 at 1:16 pm #213242ok Some of the mystery has been deciphered here.. 2 revelations:

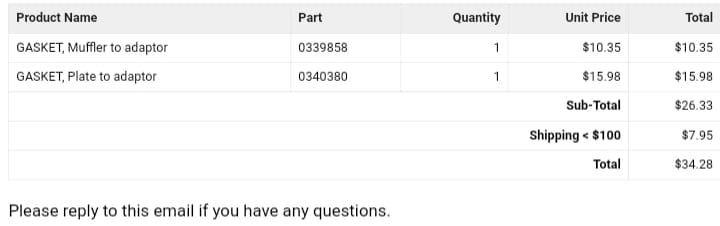

so my “Exhaust adapter plate” i’ve been working on is beneath another plate called the “adapter plate” (identified in pics below), and I had been tracing how the water enters thru the exhaust plate, then thru the adapter plate, into the motor then out, I had expected the hot water and the exhaust to combine right under the engine like I’m familiar with in transoms, well guess what, the water doesn’t combine w/exhaust until it gets about a 18 inches away inside the tall muffler assembly.

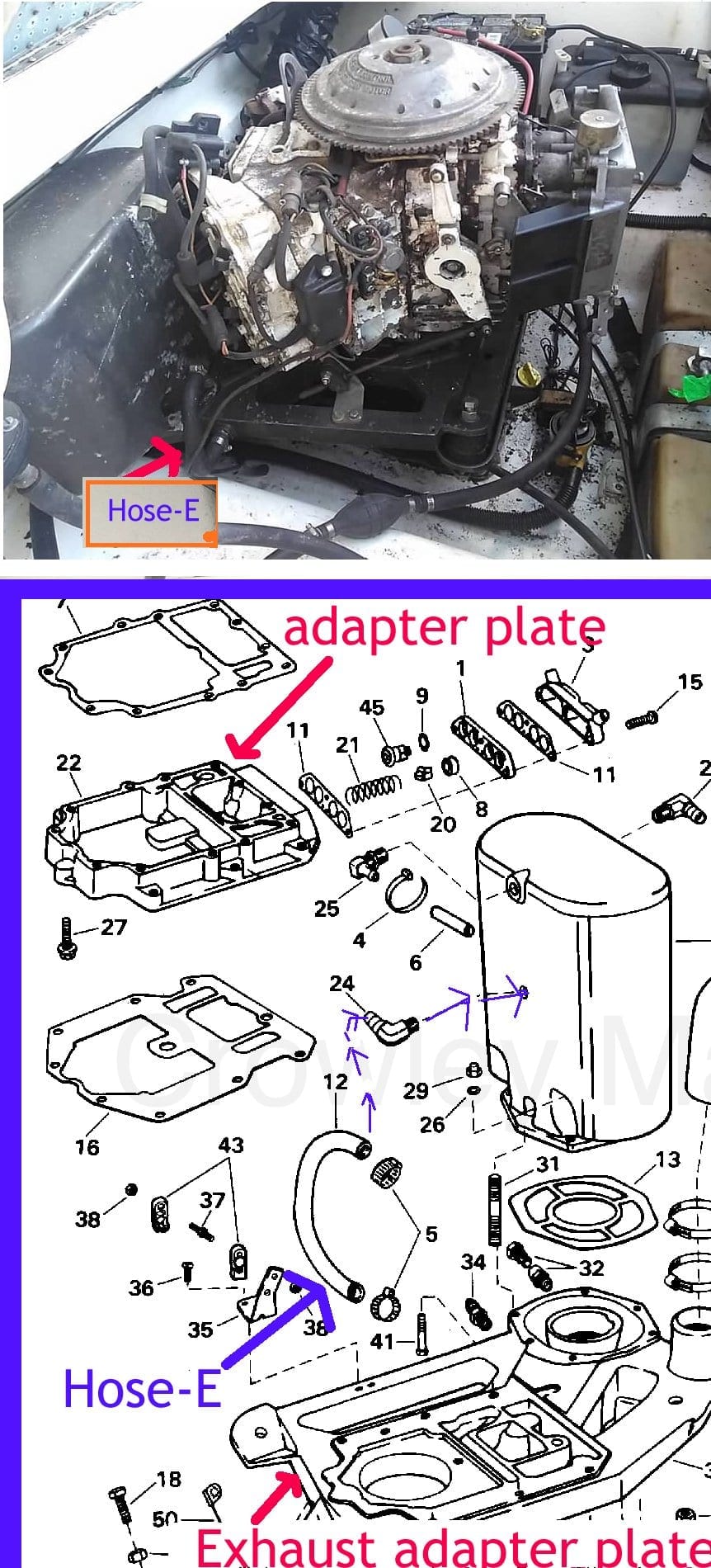

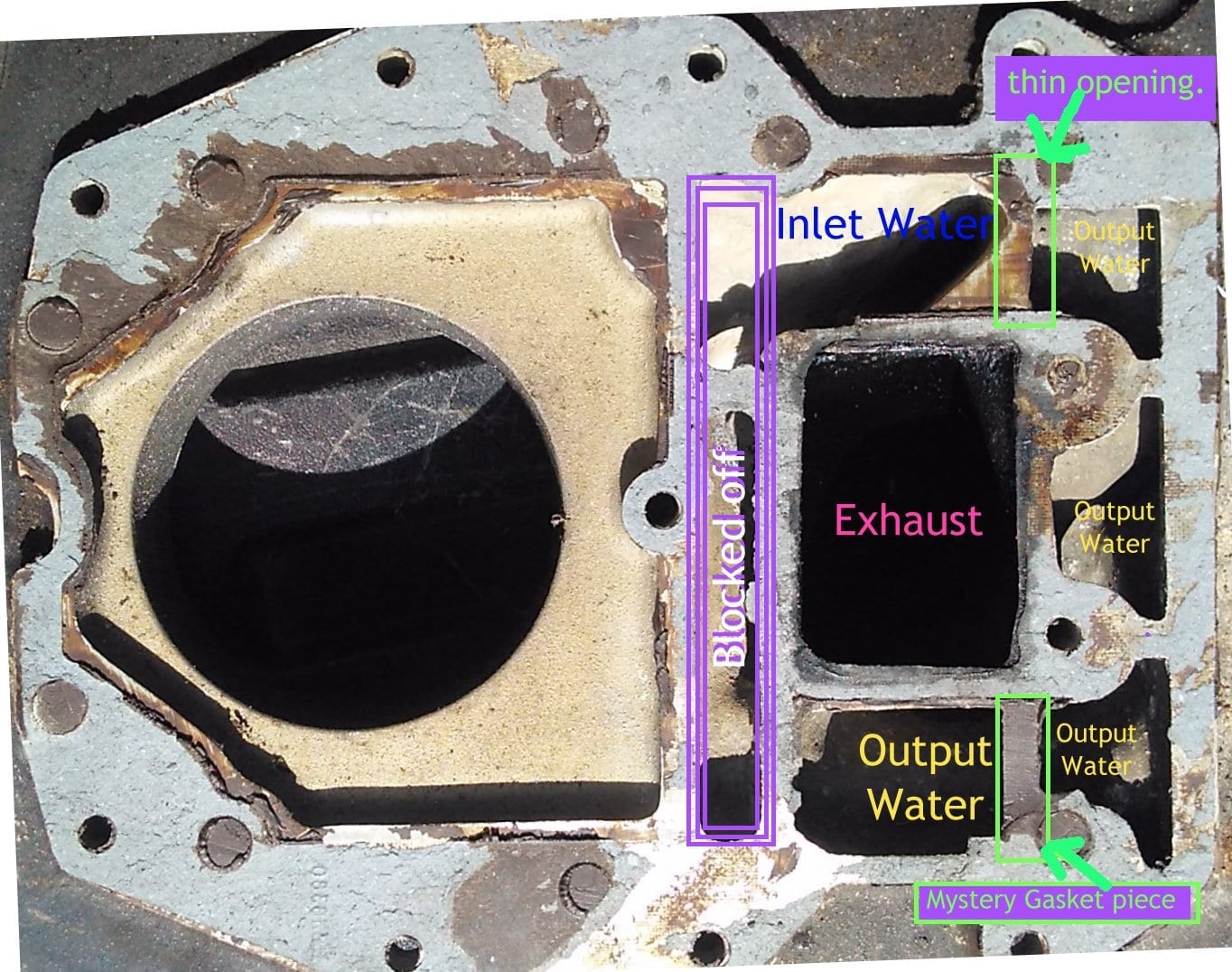

But on the way there it actually exits the entire adapter plate, travels thru a hose (I’ll call it Hose-E?) then to re-enter at the muffler assembly. whew.. oknow I had noticed that cooling water enters but has a way to get between the input water and the output pathways shown on the starboard on in the top green square of this picture. (it’s 1 inch wide but only the thickness of a gasket thick) that’s not a lot of water..but some

Then welder working on welding the plate noticed that there was/is a rogue gasket material bar on the port side (noted in lower green square in the pic above).. we have come to accept that the previous owner had actually put the gasket on- upside-down.

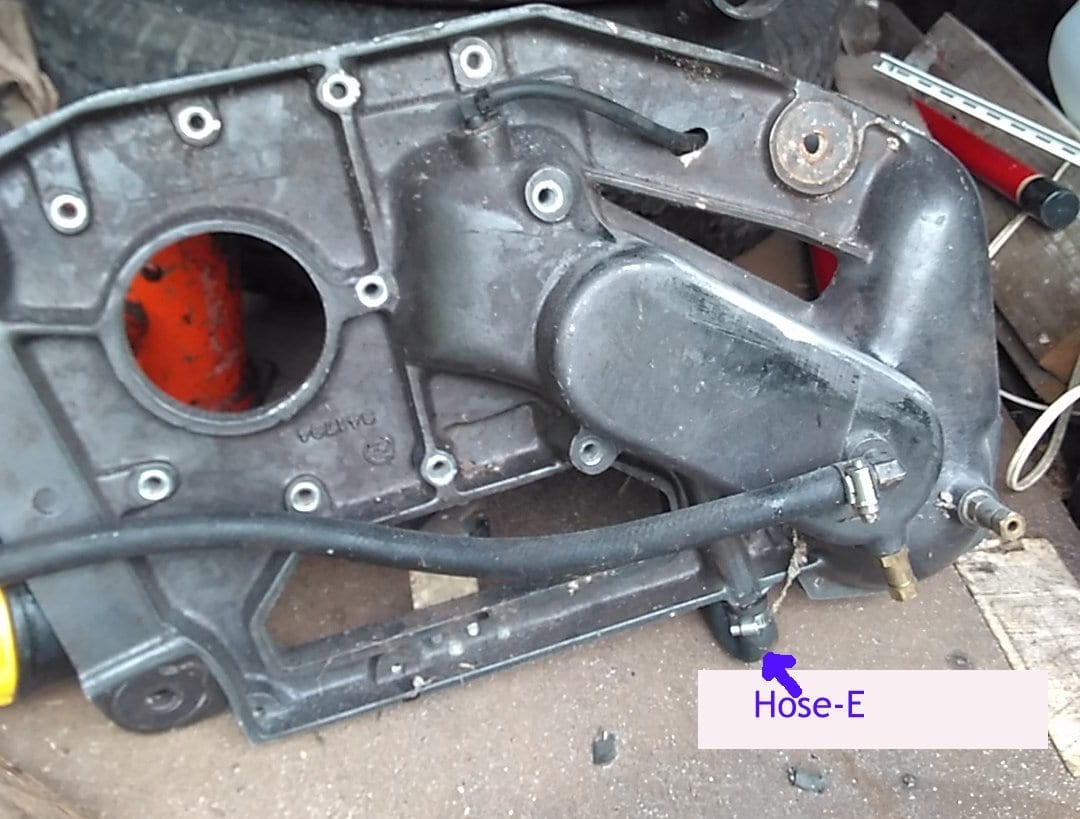

Now, I since I thought water and exhaust mixed in the exhaust plate (it doesn’t) I had blocked “Hose-E” which I had figured was just overflow or something. as shown in this stock photo of someone else’s engine

so regardless, I couldn’t blow any air thru the engine cooling because it couldn’t escape since I had unwittingly blocked off “Hose-E” .

I won’t know much more till the new gaskets arrive and I do the re-assemble

September 2, 2020 at 11:10 am #213285I also just realized that my 115hp bubbleback had those vents you mentioned at the top of the cylinder water jackets. This 140hp does not have them. Clearly the engine was designed to work without them.. should i drill and 1/8th inch tap them in or just let it go? My other boat is a 120hp straight4 mercury inboatd jetboat it has this style hole in its chrysler force block but its plugged off.

September 2, 2020 at 6:04 pm #213344OK, sounds like that mystery is solved…I would have to look at it closely but I think it makes sense. Water exits powerhead adapter through that hose you had blocked off, then off to cool the exhaust elbow…

I see that the heads to this unit are vented, tied together, then exit through the elbow/muffler as well…

http://epc.brp.com/Index.aspx?lang=E&s1=a6780bbe-a9cf-4155-8013-c15af250e35bSeptember 5, 2020 at 7:09 pm #213573anyone happen to know the correct torque for the bolts to bolt this 140hp at the base?

the bolts are 1/2″ hex drive and the shank of the bolts seem to be 3/8″ i believe.September 5, 2020 at 8:30 pm #213579September 5, 2020 at 8:31 pm #213587 -

AuthorPosts

- You must be logged in to reply to this topic.