Home › Forum › Ask A Member › Backfire/misfire thru carb

- This topic has 105 replies, 9 voices, and was last updated 1 year, 7 months ago by

Beno.

Beno.

-

AuthorPosts

-

September 5, 2020 at 8:38 pm #213593September 5, 2020 at 9:09 pm #213598

Making great progress

September 5, 2020 at 10:11 pm #213603September 5, 2020 at 10:12 pm #213608September 5, 2020 at 10:14 pm #213612ok, I found a flywheel puller and popped the flywheel… looked nice inside, there were 4 flat head screws and keepers, I had to re-bend each keeper to stop them from grabbing onto the trigger so hard… was odd. all 4 were wrong? noone noticed before now that the trigger couldn’t move but me?

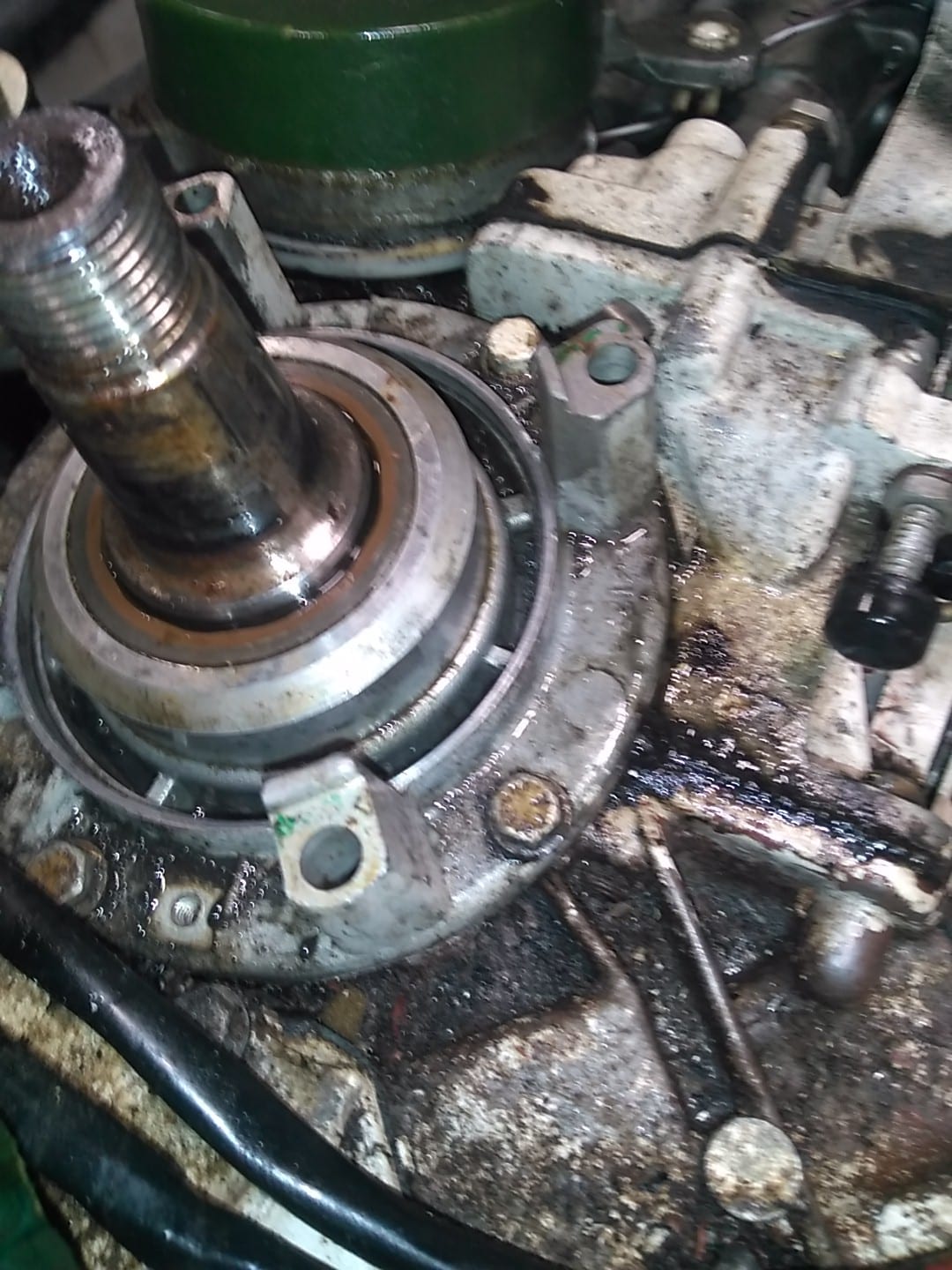

the flywheel nut is bigger than 1 1/4″ whats the correct socket (im making due with a strange grey 36mm I have now but its touch n go)

and the big question.. whats the correct torque for the flywheel nut?

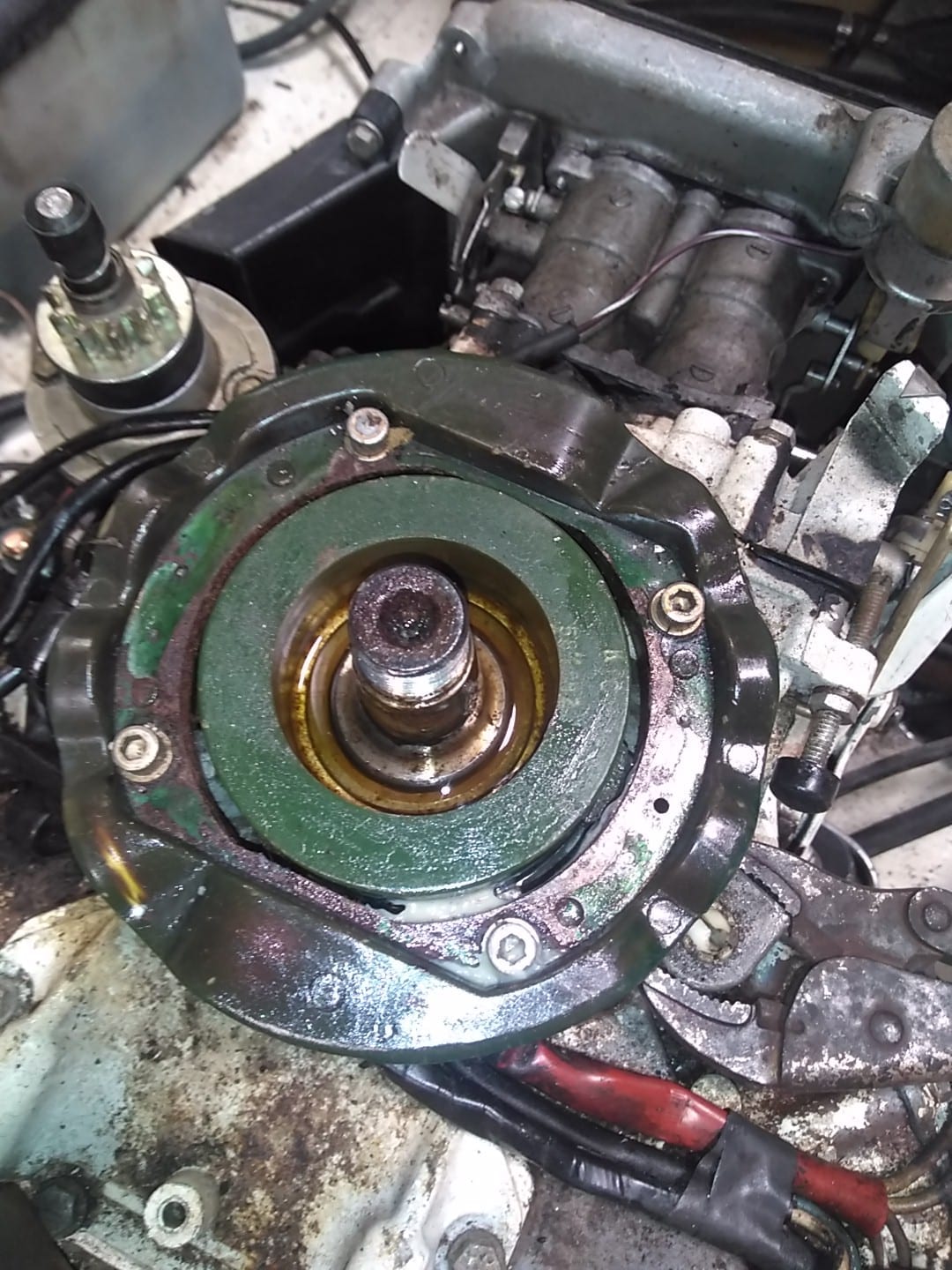

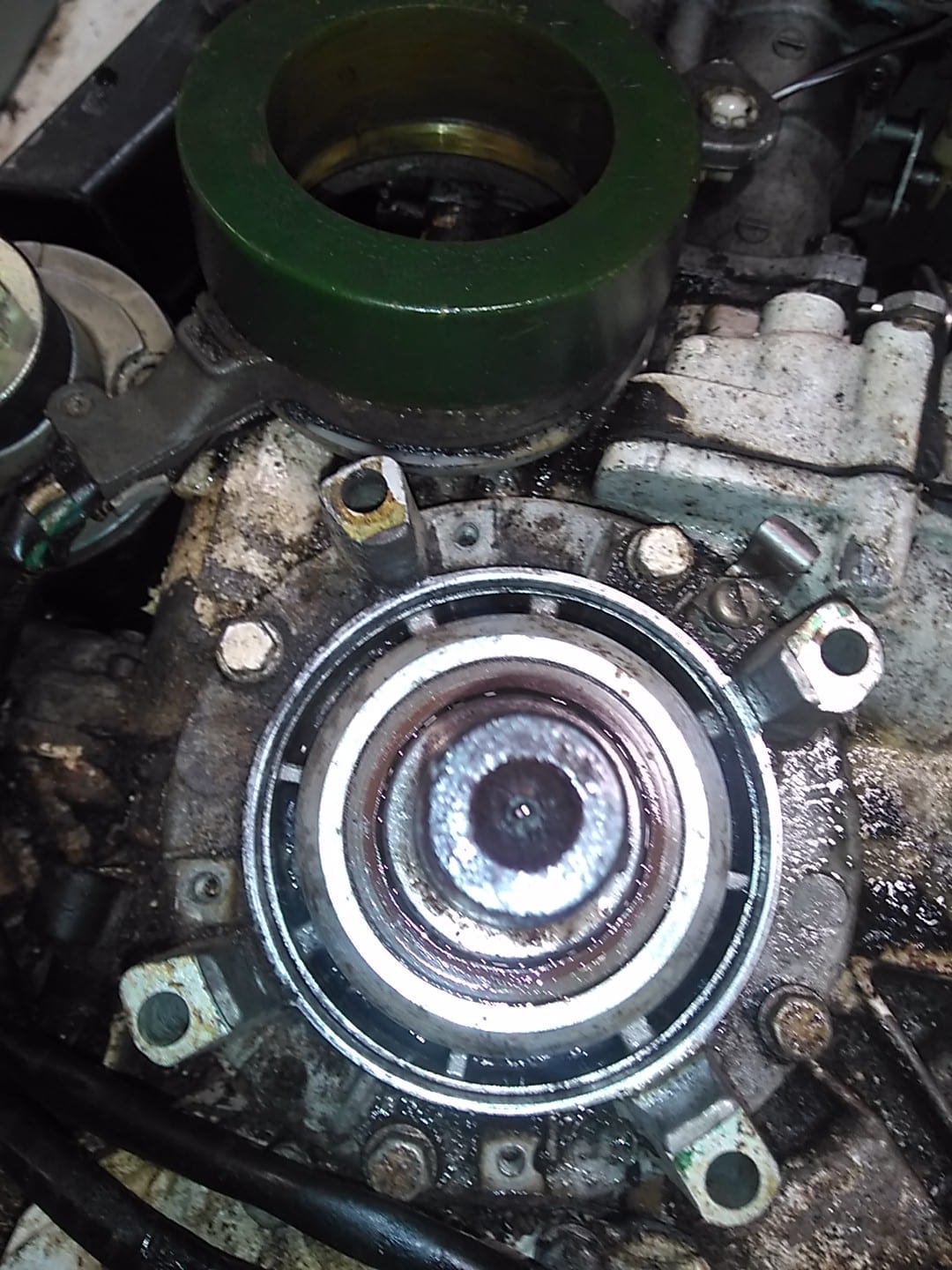

September 6, 2020 at 7:23 am #213618OK, well I’m not sure what picture I missed…But, that upper main is not installed with its proper hardware… I see one of the sensor coil plastic bushing clamps (upper right) clamped down improperly and facing in the wrong direction… There is supposed to be four clamps, four smaller machine screws that thread into the upper bearing. Needless to say, the clamps point in towards the crankshaft. The clamps will usually keep the plastic bushing from rotating in the upper bearing, this is normal . The sensor coil assembly spins inside the plastic bushing. The OMC moly lube is used to lubricate the brass/bronze pilot bushing inside the sensor assembly. Use regular outboard oil to lubricate the plastic bushing. The correct flywheel nut torque is: 105 ft. pounds.

No comment on the home made puller rig, will just say don’t get hurt. You will need a heavy ring gear holder to torque the flywheel…

http://epc.brp.com/Index.aspx?lang=E&s1=6799ea59-4d96-43e7-88b6-fa36e884bdd6 This is the link to the BRP parts look up, you can find the turbo jet break down in here…September 6, 2020 at 2:10 pm #213647Sorry I missed taking a pic of the flanges as I found them, all four were mounted correctly, Just too tight, had to modify all 4.. strange.

in the pic you saw I had already removed 3 flanges and one in the upper right I had just turned around.I was able to hold the flywheel with 4 pair of vise grips strategically located, I guessed and torqued the flywheel to 140lbs (35 over).. seems to be ok for now tho.

That sanford n son Flywheel puller has come thru in the past, I keep it way in the back of the tool cabinet in a box labeled “stale crackers” and never admit ownership to anyone.

I had to pull the flywheel twice tho, after reading online that the flywheel and crack mating-surfaces had to be immaculately clean, and I had reassembled mine with oil everywhere. pulled and cleaned, then torqued.

next step is the fuel tank, replace fuel line, canvas hatch cover and seats!

September 6, 2020 at 10:35 pm #213682hooked up the garden hose water. engine runs cool. isnt’ happy about running till it gets warm… does little kickbacks.

Canvas started and finished in one night..

September 6, 2020 at 10:36 pm #213683September 6, 2020 at 11:00 pm #213690 -

AuthorPosts

- You must be logged in to reply to this topic.