Home › Forum › Ask A Member › Backfire/misfire thru carb

- This topic has 105 replies, 9 voices, and was last updated 1 year, 7 months ago by

Beno.

Beno.

-

AuthorPosts

-

July 5, 2021 at 12:59 am #241985

The new #395448 kit will fix his link popping out problem. Carry on fleetwin! Excellent job.

August 7, 2021 at 12:09 pm #244357Fleetwin,

Just listed that boat setup for sale and had a guy start emailing me about the engine swap. he seems totally convinced that this engine swap cannot work (the way it is working, btw) the donor 140hp motor is a 1978, or in any other case he basically claims the setup is just going to “poof” at any time.He’s key points he’s using: “In 1991 The V4 crossflow crankshafts changed in 1991 so if you have a earlier engine than a 91 the splines on the crank are not a exact match to the jet drive.”

– on this: if true, I cannot see how the engine would have installed at all??And ” Your cooling system has not been modified for the Turbo Jet set up , the Turbo Jets had cooling problems from the factory add some sand and poof goes the motor . Very

important when swapping a outboard engine to the jet drive .”– on this: I’ve been monitoring the temp and it seems to run nice and within bounds. the temp warning sensors are all in place, just in case. the only difference I can see is the little 1/8″ NPT air tubes on the top of the cylinder heads…

1 user thanked author for this post.

August 7, 2021 at 1:46 pm #244371Well, he is correct, to a point…The splines themselves didn’t actually change, but the way they were sealed from water was changed…. The older models, like the 78 powerhead you are using had an oring just underneath the splines that fit up into the crank slightly to help keep water out. The later models he mentions use a two seal set up and no oring…. The top seal in the lower crankcase head seals the crankcase off from the outside. The lower seal fits over the driveshaft to seal the water out… So, on the outboard models, the driveshafts were different even though the splines themselves were the same. Older driveshafts had a groove below the splines where the oring fit in, newer driveshafts had no groove, because the lower seal in the housing was there to seal off the splines….Sometimes, there is a slight difference in driveshaft height that could actually bind up conventional outboards when mismatched parts are used So, your set up certainly will work, but may not be ideal in terms of sealing the crank/input shaft splines….Hope you greased them liberally during assembly.

And yes, the turbo jet cylinder heads had the vent nipples on top of the heads to help bleed air out of the block, the turbo jet cooling inlet is subject to air intrusion more so than the regular outboard. Can’t remember if you used the turbo jet heads with the elbows, or put the elbows in the original heads of the 140hp powerhead…

As far as longevity goes, that old 140hp powerhead had more compression than the later models, like your turbo jet, this is why newer model V4s were rated at 115hp instead of 140, they had been “detuned” in an effort to help them survive on newer lower octane/unleaded fuels. But, this is something I have discussed with you in the past….A relatively easy way to combat this issue would be to use the original turbo jet cylinder heads on the older 140hp powerhead…

It does appear that the turbo jet crankcase is a different part number when comparted to the conventional outboard….Just what the difference is , I don’t know. Could be very minor, or perhaps the porting is a bit different for the different applications…

Nonetheless, like you say, the older powerhead is in place and does work…. Hope you can sell it off soon….Again, not one of OMC’s best efforts…August 7, 2021 at 11:30 pm #244418hmm well I definitely should have greased more.. never thought of it.

Clearly you know more than the guy who has been messaging me, you’re well composed, researched and through and understand the concept of proof of claim…..whereas This guy emailing me the gloom and doom is headstrong, arrogant and self serving, but being a IT administrator I deal with those people all the time. I feel I can always learn something (if I try really hard) from anyone, regardless of their style.

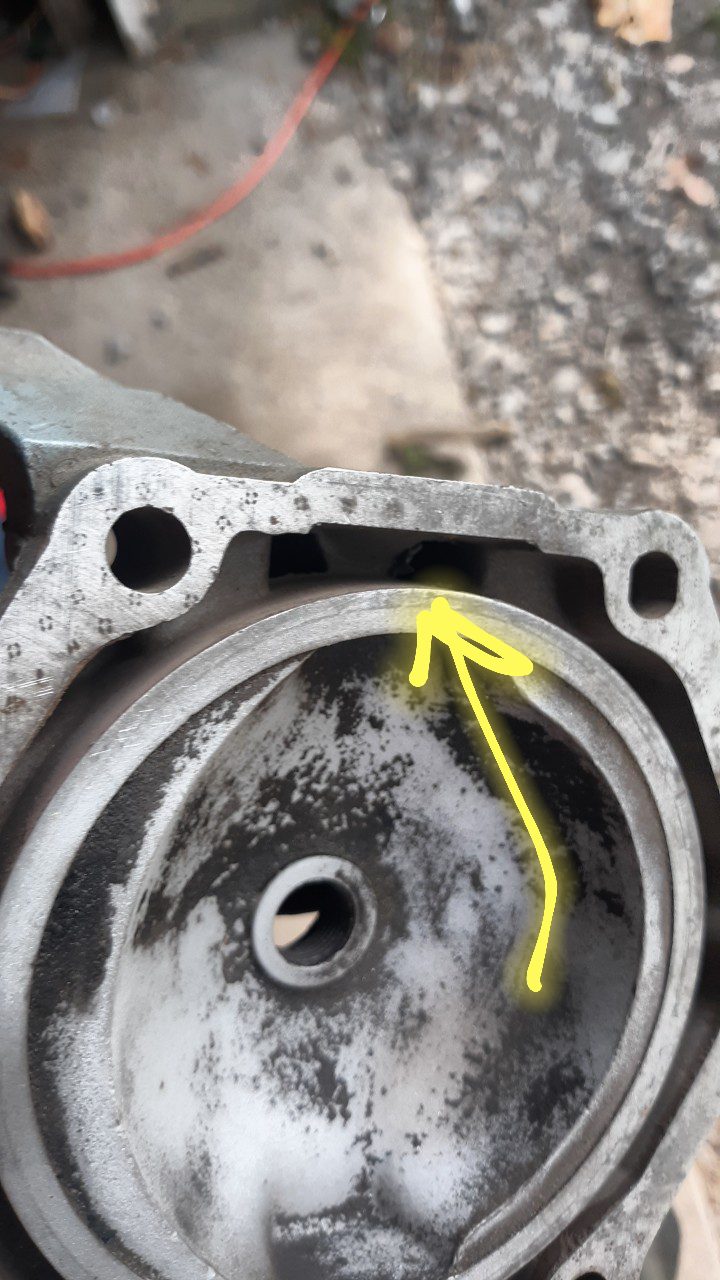

I went and got a omc v4 head and looked over the way the cooling water flow works. I really can’t see how having those little NPT Thread openings at the top truly help.

maybe it lets air out quicker in the beginning before water gets thru the engine?.. weird. I’m impressed with the whole cooling design. (although I was never impressed with the way the thermostats were designed.. hard to get trapped air out of the block with that setup.. there are tiny holes to let air out.. a little gunk and thats clogged.I don’t like the idea of drilling and tapping the head because of aluminum filings dropping down into the cooling jacket… but I could pull the cylinder gasket covers and drill that and thread them.. should do exactly the same result.? I’ll post pics of what I mean in a sec.

August 7, 2021 at 11:49 pm #244419August 8, 2021 at 6:08 am #244429I don’t know anything about Turbo Jets….thank God, apparently….but I can help with the earlier question about the fuel gauge. The back of the gauge should have three wires going to it, most likely black, purple and pink. Black is battery ground. Purple should be key-on positive 12 volts. Pink is the wire that carries the “signal” from the sender in the tank. On the tank sender itself, you should see a pink and a black wire. If they both look black, the pink is probably covered with black mold! Anyway, there is never any 12 volt power at the sender. Do not ever try to apply any either, or you might be meeting your make sooner than you’d hoped. First, check that you have power and ground to the back of the gauge, with the key on. If so, then REMOVE the pink wire from the center of the sender and momentarily ground the pink wire, while observing the gauge. It should go full scale. If it doesn’t, you either have a gauge problem or a boat wiring open circuit. More on that later, if you need it; but that’s usually not the case. If the gauge goes full scale in the previous test, you most likely have a bad sender Make sure the connections on the sender are nice and clean. If it still doesn’t work, measure the ohms across the sender (pink wire is still removed) between the center terminal and the ground terminal. It should be between 33 and 240 ohms, depending on the level in the tank. If you don’t get a reading in this range, the sender itself is bad and will need to be replaced. There are after market senders available (Moeller for one) that can be set up to fit the depth of the tank. You will need to know the depth of the tank in order to buy a sender that will be in the right depth range to adapt to your tank.

Long live American manufacturing!

August 8, 2021 at 4:55 pm #244470OK, agreed that the thermostat set up is terrible…You can’t get at the bolts on the conventional outboards, not to mention having them rusted in place…Then trying to get all those pieces/parts/springs/gaskets back installed properly is usually an exercise in frustration….

There is much more room under the top of the head for those elbows, and it is at the top of the water flow circuit, so this greatly reduces the chance that air will get trapped in the system…If you are going to do anything, I would probably just install the original black turbo jet heads/elbows back on the 140hp powerhead. When you have the heads off, compare the combustion chambers and you will see that the turbo jet heads have much less “squish” resulting in lower compression/longer engine life. There isn’t much meat on the cylinder head water cover for threads, and very little room behind the cover as well. Again, the nature of this jet system is prone to taking in alot of air while bouncing around, so I feel the elbows would constantly be purging air, not just when first started. Be sure to replace the head gaskets if you decide to make this swap.

As far as the fellow who is emailing you, I’m certainly not saying he is “wrong”. But, obviously the powerhead swap works. The trick will be longevity….These things are subject to harsh use, so they are more likely to have overheat/detonation/preignition issues. Get it buttoned up, and sell it off….August 8, 2021 at 7:20 pm #244480I actually sold the turbojet longblock complete years ago. the heads went with it.. but I’m sure I can get more on Fleabay. I’ll keep an eye out for them on ebay.

I would need new head bolts and 2 new gaskets if I removed the head right?On the fuel gauge that is great info I appreciate it. But what happened is that the gauge was working and for some reason (it’s like a 16 gallon tank) the sensor doesn’t start to read of Empty till you get to 8 gallons.. then it goes up to Full as you get to 16/16 gallons. something new every day.

August 8, 2021 at 10:50 pm #244493OK, so the original powerhead is gone. I would just order the OEM plastic elbows, remove the existing heads, and drill/tap them for the elbows…. Use new head gaskets, the old head bolts should be fine provided no one has buggered up the hex heads or used excessive heat on them…. Just tell the new owner to use premium fuel, and mix the oil a little heavier than 50:1 recommendation….

August 8, 2021 at 11:22 pm #244494as I recall one of the cylinders went Real bad.. so it’s likely only one of the heads would have been salvaged anyway.

My experience is that permium fuel runs VERY hot.. are you sure the increase in heat is worth the increase in longevity?

-

AuthorPosts

- You must be logged in to reply to this topic.