Home › Forum › Ask A Member › Big Twin 35 gear case to oil retainer dowel.

- This topic has 8 replies, 5 voices, and was last updated 7 years, 6 months ago by

boscovius.

boscovius.

-

AuthorPosts

-

September 14, 2017 at 2:50 pm #8226

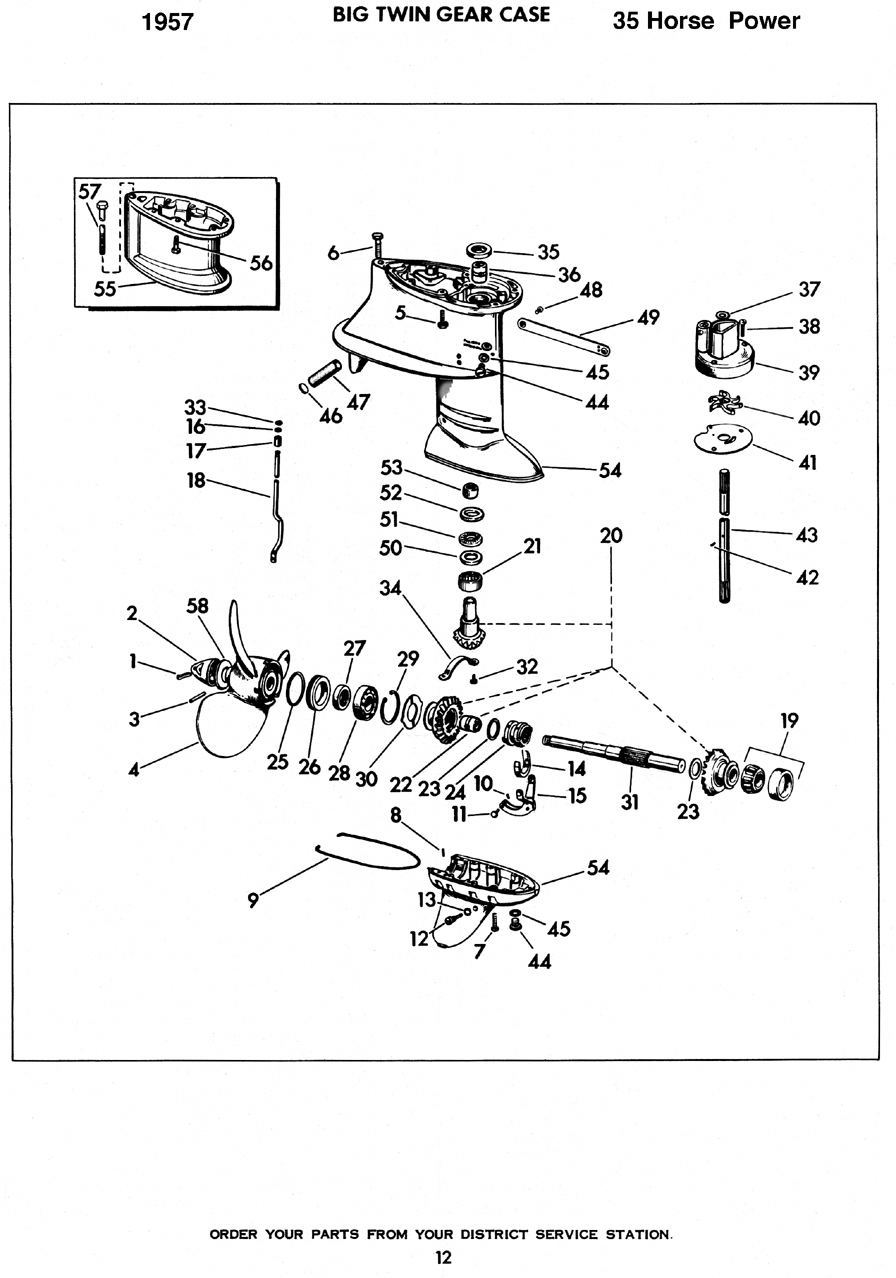

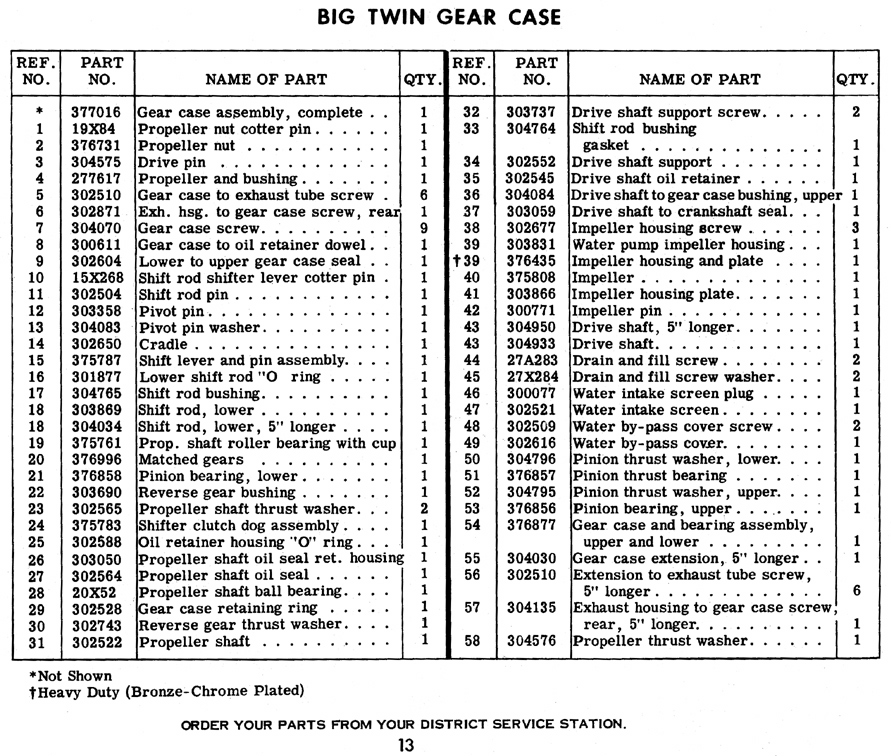

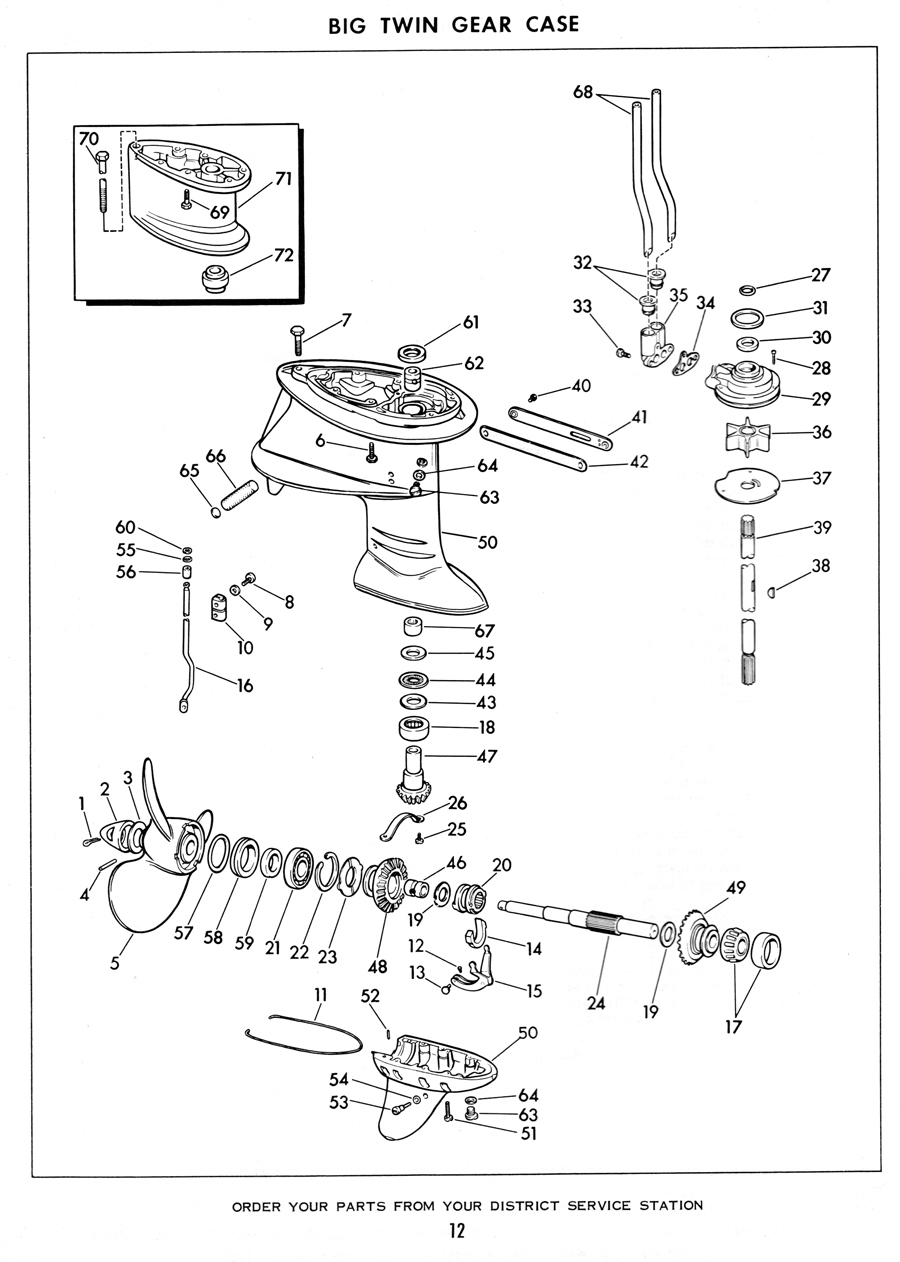

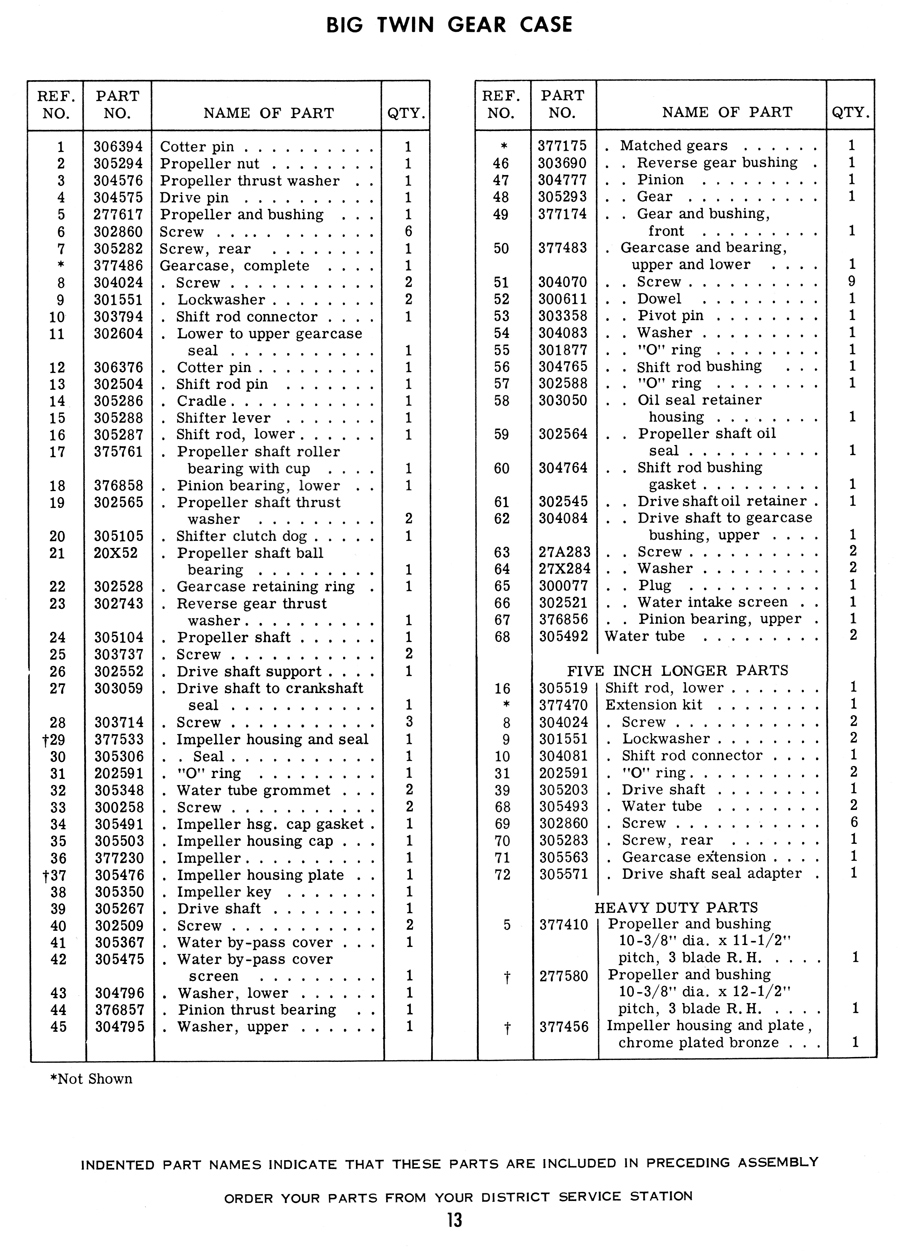

I’m rebuilding two of these lower units that I use on my 1957 35 hp Big Twin. Unfortunately, one of the housings has a broken gear case to oil retainer dowel. Very little of the dowel is protruding from the housing, and I did my best to pry it out, but no luck. Anyone ever had any luck drilling one of these out? I’m willing to give it a go, but I’d hate to wreck it. As it is, I think there is too little of the dowel left to serve it’s intended purpose. The part number I’m referencing is 030061-dowel. I am not certain, but it may be the very same part as the impeller pin on the drive shaft. Any clarification on that would be helpful as well.

Thanks in advance for any advice.

September 14, 2017 at 4:02 pm #64874I’ve actually had luck drilling them out from the other side. Drill a hole, aiming for the top of the pin. Watch your metal shavings – they’ll change when you hit the pin. Once there, use a punch to drive the pin out from the side you drilled. Fill the hole with JB Weld or Marine Tex epoxy and set a new pin in place before the epoxy sets.

September 14, 2017 at 8:45 pm #64886Chinewalker. Are you referring to drilling a pin out of a drive shaft? Because after taking a close look at my lower unit housing, I don’t see any realistic way of using a drill and having any hope of intercepting the pin. Unless I go from the side of the housing close to it. At any rate, I was thinking it would be better to attempt to hit it with a center punch and then put a small diameter drill into it just far enough to enable the use of a screw extractor. Perhaps, if you don’t mind, you could describe your approach a bit clearer.

September 14, 2017 at 9:21 pm #64887You confused us with an incomplete part number. Should be 300611, and it is not the same as the impeller drive pin. I’ve never tried chinewalkers approach, but I have drilled out similar dowels in other locations, using your approach. The tricky part is keeping the drill from walking out into the softer aluminum. Best to use a drill press and start with a smaller hole if you have the equipment.

Another approach is to simply drill a new hole beside the original. It’s only purpose is to prevent the seal housing from blowing out of the case.

September 14, 2017 at 10:11 pm #64888I do what Frank stated, drill new hole right beside it.

Wish they would not have drilled the hole for the pin so deep? NO idea there!

September 15, 2017 at 9:29 am #64910I apologize for the incomplete part number. And thank you FrankR for the alternative idea. I suppose drilling a new hole might be the easiest thing to do, as long as I file off the remaining nub of original dowel and make it flush with the housing. Fortunately, I have some friends in the maintenance department where I work and they have a vast arsenal of tools, including drill presses and milling machines.

September 15, 2017 at 5:34 pm #64935To be clear, the ’57 & ’58 BigTwins have the same gear case . . . 😉

September 15, 2017 at 5:44 pm #64938

September 15, 2017 at 5:44 pm #64938The super quiet Lark has a different water pump . . . 🙂

October 17, 2017 at 9:20 am #66315

October 17, 2017 at 9:20 am #66315I just wanted to update this post. I was successfully able to remove the dowel pin. I used a Alden 4507P Grabit Micro, which is a 4 piece bolt extractor for very small bolts, and the use of the drill press at the shop where I work. Thanks again to everyone for their help and advice.

-

AuthorPosts

- You must be logged in to reply to this topic.