Home › Forum › Ask A Member › Caps for John

- This topic has 23 replies, 10 voices, and was last updated 9 months, 1 week ago by

crosbyman.

-

AuthorPosts

-

January 29, 2024 at 9:49 pm #284472

Finn, thanks for your (and your boat’s) vote of confidence.

I’ll have to try some out soon!Prepare to be boarded!

January 29, 2024 at 11:16 pm #284473I would like to put my word in for the Ceramic Capacitors. I got my first two at Constantine from Jay Miller, and since then have bought a few more. They run great in my ’62 Evinrude, and I plan to put them in everything else that needs condensers. It takes a little bit of soldering skill to get them together but well worth it.

https://www.digikey.com/en/products/detail/murata-electronics/krm55tr73a224mh01k/4905676

Thank Finn!

Exactly the information we were looking for. You didn’t happen to document via pictures your handiwork at wiring up these caps, did you? If not, how about a few ‘do’s and dont’s’?

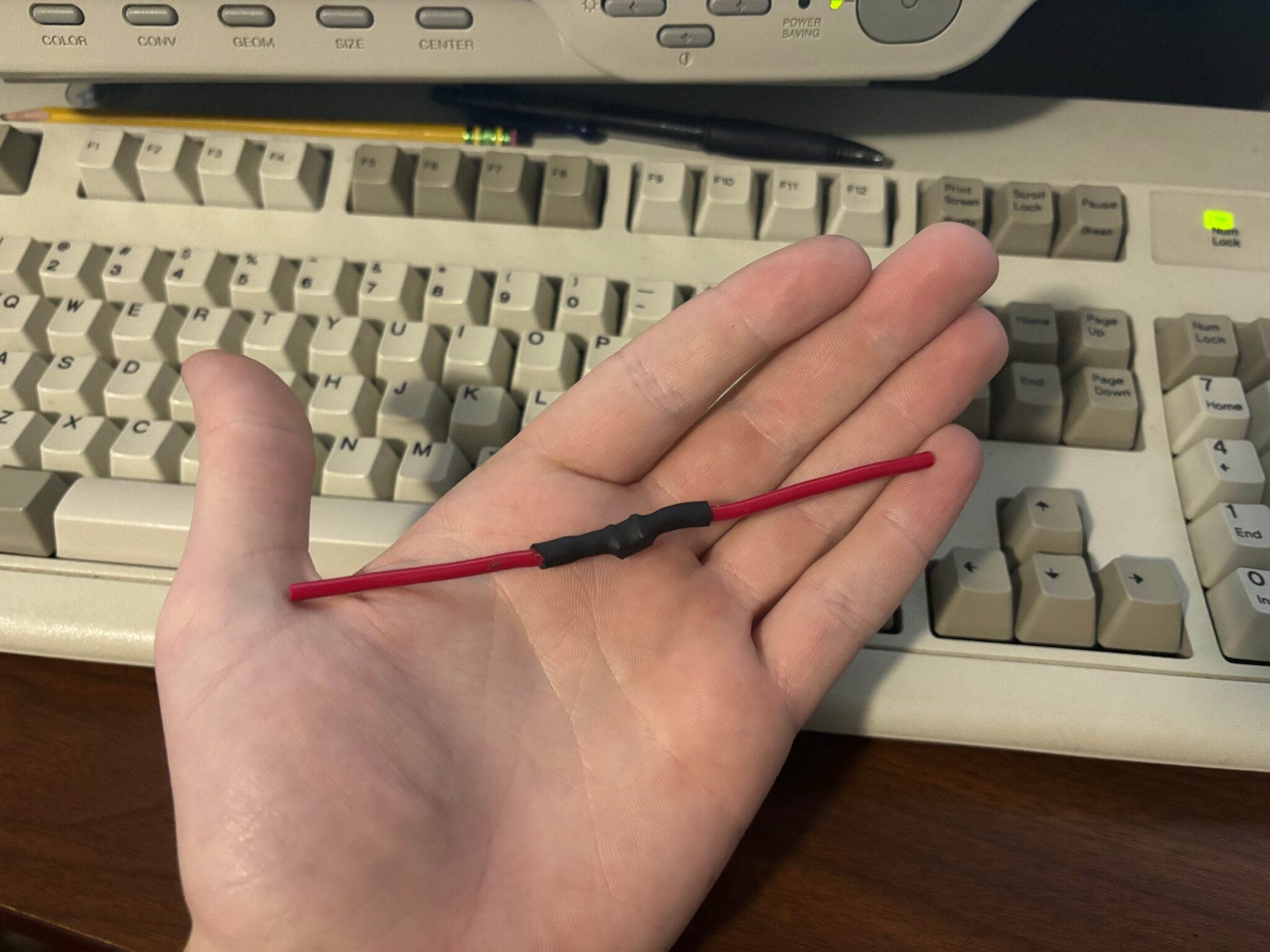

I’m ordering a few right now. Even if I have to figure it out on my own, you supplied a great picture of what the end result is supposed to look like.

Thx

Best Regards

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A

49 Sea King 5hp GG9014A

48 Johnson TD20

49 Johnson TD20

54 Johnson QD15

55 Johnson CD12January 30, 2024 at 10:36 am #284477I plan on making a detailed video on the process next time I order more, but here is the short version:

The soldering iron needs to be HOT. I ran mine at 350 degrees Celsius, but I probably should go hotter. Spend as little time as possible touching the iron to the capacitor. Use rosin core 60/40 solder. Do not use any flux. Tin both ends of the capacitor and tin the wire. I found that I needed a considerable amount of solder on the end of the wire for it to easily bond and hold to the capacitor. Hold the wire to the capacitor and just touch it with the iron till the solder melts. Polarity does not matter when installing the caps.

Some of this advice is what I was told by Jay Miller and some is what I learned by doing it myself.

I used 16 gauge wire and 5/16 in. double wall, adhesive-lined heat shrink with a 4:1 shrink ratio.

January 30, 2024 at 11:57 am #284505I also worked up some caps this past weekend.As far as the smaller square ones go,I used same method as Finn but used 18 gauge wire.I put some Vishay cylinder caps in some old caps as well.I used the taller old OMC condenser cans like the TD,HD etc used.Even though they are a little taller than the newer cans,I thing they will fit under the flywheel on the later models and mount the same way.

January 30, 2024 at 12:22 pm #284507I never even knew there was such a thing as …..

“double wall, adhesive-lined heat shrink with a 4:1 shrink ratio.”

Finn, what Brand / Model of soldering gun are you using?

Mine, a Sears, I bought new 40 years ago, and has been great,

but it’s giving me a little trouble lately. I can’t remember,

but I think mine was either 150 or 250 Watts.

Thanks.Prepare to be boarded!

January 30, 2024 at 5:54 pm #284517Buc, I’m using a TS101 soldering iron commonly used for small electronics and computers. I run it off of a 65w psu running at 20v.

January 30, 2024 at 6:14 pm #284519Buc, I’m using a TS101 soldering iron commonly used for small electronics and computers. I run it off of a 65w psu running at 20v.

Thanks Finn, I watched a YouTube video about them.

They seem to perform amazingly well for such a little thing.

I can see where it would be handy for electronics work.Prepare to be boarded!

January 31, 2024 at 10:13 am #284520

This is really helpful for condensers that are of

unusual construction, difficult to mount a substitute,

and no longed available. Like the ones found in

the Wico magneto. They’re are always bad.

Not sure how successful I’ll be soldering the

wires on with my old Weller soldering gun though.

Tubs

. January 31, 2024 at 11:13 am #284521

January 31, 2024 at 11:13 am #284521Just a caution using the old WICO cans… I’ve rebuilt many of these and had about 20% fail a leakage test. I found that the insulator on top between the can and the post can conduct enough to make them useless. The black ones seem to be better than the red fiber versions, but I’ve seen failures with both.

Tom

January 31, 2024 at 12:04 pm #284523

Thank Tom for the heads up. Your response has me thinking I’ll

just retain enough of the can to keep the mounting tab. Epoxy the

cap in what remains, ground one wire, and attach the other to the

points. I’m also now considering just gluing the cap to the mag.

plate somewhere. Lots of options with something thus small.

Tubs

. -

AuthorPosts

- You must be logged in to reply to this topic.