Home › Forum › Ask A Member › Carburetor principles

- This topic has 21 replies, 9 voices, and was last updated 5 years, 10 months ago by

dwdropinn.

-

AuthorPosts

-

August 14, 2019 at 11:45 pm #181347

Hello, I have a 1952 Evinrude fleetwin

I haven’t run into this problem before, I must be overlooking something. The engine starts on one pull, runs and idles smoothly.

When I move the lever to the right, rpms increase, but to a medium slow engine speed. The compression has t been checked, but feels strong, the spark looks strong and I cleaned the carb. I plan on cleaning the carb again this weekend, but I have a question about the reed plate. Many of my motors don’t have this, what is it’s purpose and is it possible to have installed it backwards or something and experience the issue I am having? Any thoughts most appreciated!August 15, 2019 at 1:54 am #181348So your question is about the purpose of the reed plate? Actually, it is so simple that most of us don’t even give it a second thought, nevertheless it is a worthy question. It all begins with the basic theory of operation of a two-stroke engine. On the piston’s up-stroke, a partial vacuum is formed within the crankcase. That low pressure draws in air and fuel through the carburetor. Then on the piston’s down-stroke, that air/fuel charge is compressed. When the piston nears the bottom of it’s stroke, intake ports open and the compressed air/fuel escapes the crankcase and enters the cylinder. Very soon, the intake ports close again as the piston starts it’s up-stroke and the process begins all over again. Since the question concerns reeds, I am deliberately leaving out the rest of the story,

OK, so we now see how the air/fuel gets into the crankcase. There is one other thing to understand. The air is being drawn in on the up-stroke and being compressed on the down-stroke. So why doesn’t it simply blow back out from where it came, back through the carburetor? Aha, enter the reed valves. They are simply a one-way flapper valve. They pull open in one direction (vacuum) and slap shut in the other direction (pressure). No, obviously they wouldn’t work if installed backwards if that were even possible.

The other part of the question concerns why some two-strokes don’t have reeds. Well they may not have reeds, but they do have some sort of valve to allow air to enter the crankcase on the up-stroke, but not blow back out on the down-stroke. Most often, that is accomplished by some sort of rotating valve (rotary valve engines), or a special port or ports opened and closed by the piston skirt (third port engines). Or even a combination of the two, such as the Johnson TD-TN series.

Reeds were not used on the real old designs, because metal technology didn’t exist yet. Those things are constantly flexing back and forth and would soon break if not made of a metal or other substance able to withstand all the bending. But once invented, reeds pretty much became the standard because of the simplicity, suitability over a wide RPM range, and low cost. An exception might be stuff like chainsaws where high RPM takes a back seat to slow idle. They most often use a third port design for durability, light weight, and low cost.

Hope this helps.

August 15, 2019 at 2:03 am #181349BTW, you wrote “The engine starts on one pull, runs and idles smoothly.”. With that in mind, you can rest assured that the reeds are doing their job just fine.

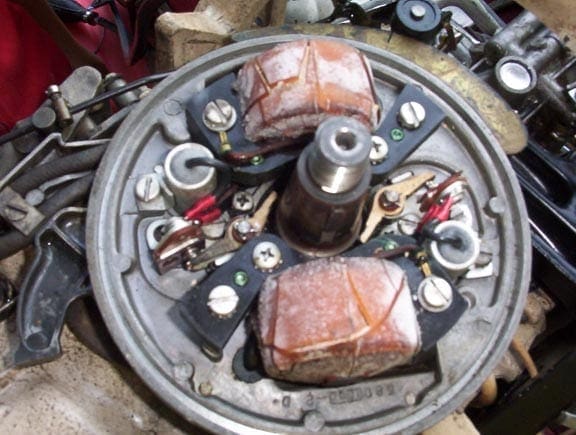

August 15, 2019 at 2:12 am #181350BTW, BTW, I’ll bet your 1952 Fleetwin won’t rev up because it is running on one cylinder due to old, no-good coils. Almost guaranteed if the original coils are still in there. Have you looked?

August 16, 2019 at 10:10 am #181429Thanks for the generous reply! Obviously, my reed valves must be working well!

I had to revisit some of my collection, I suppose my Johnson series ‘A’ accomplishes porting with the crankshaft acting as a ‘blowback’ valve?

My fleetwin does have the original coils, it would stand to reason if they are known to go bad, I should replace them. It shure runs smooth on one cylinder.

Anyone know a part number for replacement coils?August 16, 2019 at 10:46 am #181431https://www.amazon.com/Ignition-Johnson-Evinrude-Cylinders-replaces/dp/B004S6RH1M

Will thee work on an early fleetwin?August 16, 2019 at 11:24 am #181432https://www.amazon.com/Ignition-Johnson-Evinrude-Cylinders-replaces/dp/B004S6RH1M

Will thee work on an early fleetwin?

Unfortunately, I lost 9/10 of my part reference books when my computer barfed. I think that is the coils for your motor, but not totally sure. 1952 was a year of rapid change in the OMC magnetos.

August 16, 2019 at 11:28 am #181433August 16, 2019 at 11:40 am #181435A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

-

This reply was modified 4 years, 4 months ago by

Tubs.

Tubs.

August 16, 2019 at 1:03 pm #181441Has anyone tried these? They are absurdly cheap. It make me skeptical.

https://www.ebay.com/itm/2x-Ignition-Coil-For-Johnson-Evinrude-OMC-Replaces-584477-0584477-582995/143350767697?_trkparms=aid%3D111001%26algo%3DREC.SEED%26ao%3D1%26asc%3D20160908131621%26meid%3Dac2e5f1c4ac84b8ab440f6f291fa04cd%26pid%3D100678%26rk%3D1%26rkt%3D15%26sd%3D143350767697%26itm%3D143350767697%26pg%3D2481888&_trksid=p2481888.c100678.m3607&_trkparms=pageci%3A646125a5-c047-11e9-89cf-74dbd1809453%7Cparentrq%3A9b5fde3c16c0ad31c39372aafff376c8%7Ciid%3A1

But has anyone tried them? -

This reply was modified 4 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.