Home › Forum › Ask A Member › CD/AD type shock absorbers.

- This topic has 13 replies, 6 voices, and was last updated 2 years, 3 months ago by

crosbyman.

-

AuthorPosts

-

September 9, 2022 at 6:01 am #265760

Awhile ago, I picked up a fairly nice looking 1956, 7.5 Evinrude. At the time, I was told it needed a new head gasket, which I assumed might be true because it pulled over VERY easily. A few years past. Now I am getting it ready to make it’s glorious return (hopefully) at the Shelton CT, AOMCI meet. I checked the pump; but when I reassembled it, I noticed that it bound up when I tightened the pump screws. The shock absorber was binding. I put it in a hydraulic press and pushed it back down. My questions are, why did this simply go bad over time, while just sitting, and will it just pop back up again after I have pressed it back down? Thanks.

Long live American manufacturing!

September 9, 2022 at 10:55 am #265765Hard to say whether the shock is actually broken, or perhaps just stretched out a bit. I suppose it can stretch out a bit after the prop has “bumped” a few things. I am also wondering if water in the gearcase gets trapped inside that shock making the issue worse. Someday I’m gonna take one of these things apart to get a better idea of what it is all about. Compressing the driveshaft shock back down seems like a reasonable solution though, if it stretches again then I would replace it. Plenty of guys just weld the two pieces of the driveshaft together after compressing it, which seems like a fine solution as well. But, you have to make sure the two halves are “true” before welding to avoid driveshaft misalignment.

Finally, this whole device seems like “over engineering” to me. After all, isn’t the shear pin there to protect these parts?

September 9, 2022 at 11:43 am #265768Actually, these motors use a stainless ‘drive’ pin as the shock absorber protects the drive train from impact. If it is welded solid, then a softer brass ‘shear’ pin should be used. On a few of these motors, I’ve used a later six horse prop shaft as it will accept a rubber hubbed propeller.

September 9, 2022 at 11:47 am #265769Why the shock absorber? Consider the competition. Mercury made a big deal of their “No shear pin” ads. They had that splined prop shaft with multi-disc slip clutch inside the prop. Sort of worked, according to how easily the clutch slipped. Other companies also came out with their slip clutches. Anyhoo, OMC had their slip clutch that worked–the shock absorber in the gearcase, bathed in oil.

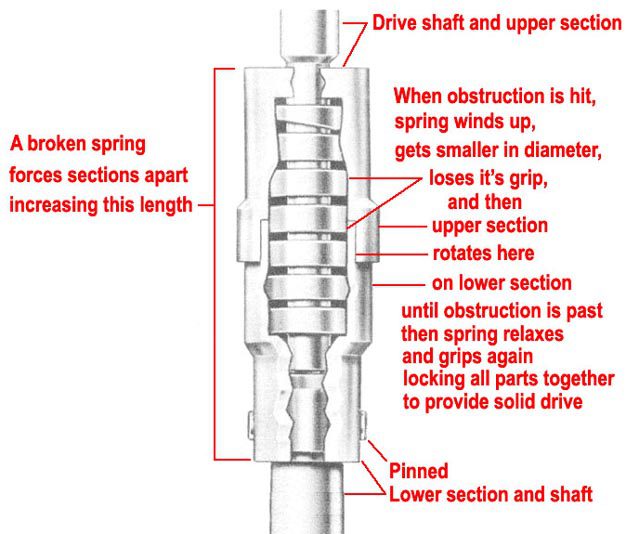

The shock absorber is in three parts, the upper and lower section housings, and the spring inside. In relaxed state, the spring is a tad larger than the ID of the housings. Pressed into the housings, the spring is compressed and grips the housings tightly. When an obstruction is happening, the spring winds up, becomes smaller in OD, and loses its grip. Then unwinds again after obstruction, and regains grip. Now for the mysterious part: It never really happens, but just suppose the spring was wound up enough to completely lose all grip inside the housings. In that case, the three parts would be free to move apart, making the assembly longer until limited by the bearing housing above it. That limitation in itself if not enough to cause jamming. But suppose you were to take it apart and replace the bearing housing or gasket, or otherwise reduce the clearance. Now it’ll jam. Pressing the shock absorber back together restores the original length and good as new.

The other scenario, of course, is the infamous broken spring. There isn’t enough room in there for the broken ends to pass each other, so it all expands and all else ceases to fit.

September 9, 2022 at 4:31 pm #265780

September 9, 2022 at 4:31 pm #265780Hmmm, if it had a broken spring, that would explain why it pulled over one minute and not the next….Probably gonna be rowin’ ‘er home at tomorrow’s meet…Thanks for all the info everyone!

Long live American manufacturing!

September 9, 2022 at 6:27 pm #265786Thanks Frank, I always assssumed the spring was somehow pinned to the housings at both ends. So this “feature” kind of works like the electric shift spring/hub clutches, without the electrical/magnetic assistance. Now I’m wondering what would make the spring “break”, considering it is not pinned to the housings at either end.

I understand now, OMC was trying to compete with the Merc features. The SS shear pin kind of “deletes” the shear pin function on purpose. So, I guess if I ever got one of these apart, I would never be able to compress the spring enough to get it back into the housings.

September 10, 2022 at 12:53 pm #265830I don’t know this for a fact, but I suspect that the spring being under stress for some 60 years is resulting metal fatigue and breakage. We sure didn’t see so many broken springs back in “The Day”.

Can’t say that I’ve ever tried to re-install a spring. But I’ve had lousy luck in trying to remove both pieces of a broken one. A couple of times where I could get the broken one out, I’ve fabricated a solid “spring” or sleeve to an interference fit and pressed it in. That locks it up, but of course no longer has the slip function.

September 11, 2022 at 6:32 am #265858Well, I ran the engine yesterday for a half hour or so and it seemed fine. Even at the end of the run, it was still idling down nicely, so the pressed-back spring held up for that long, anyway. That made a nice end to what was a perfect 10 of a day at an AOMCI meet!

Long live American manufacturing!

September 11, 2022 at 7:05 pm #265881Well, I ran the engine yesterday for a half hour or so and it seemed fine. Even at the end of the run, it was still idling down nicely, so the pressed-back spring held up for that long, anyway. That made a nice end to what was a perfect 10 of a day at an AOMCI meet!

Glad it worked out, your 18hp hummed along nicely also. Wish my day went that well. Those 7.5s are nice engines, just gotta give em plenty of oil.

September 12, 2022 at 5:36 am #265903Thanks again for that 18, Don. I just love those things!

Long live American manufacturing!

-

AuthorPosts

- You must be logged in to reply to this topic.