Home › Forum › Ask A Member › Changing the shift rod seal on my Johnson CD-12

- This topic has 34 replies, 16 voices, and was last updated 7 years, 9 months ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

February 12, 2017 at 10:05 pm #6334

Hi guys, I need to change the shift rod seal on my 1955 Johnson 5.5hp outboard. It had been leaking gear oil (clean & golden oil) whenever I laid the outboard on its back for transport. The outboard never leaked sitting upright on my motor mount in the shop. I drained the oil out of the lower unit and the oil showed that tell-tale white, cloudiness. So, I figure it’s a leak around the shift shaft seal.

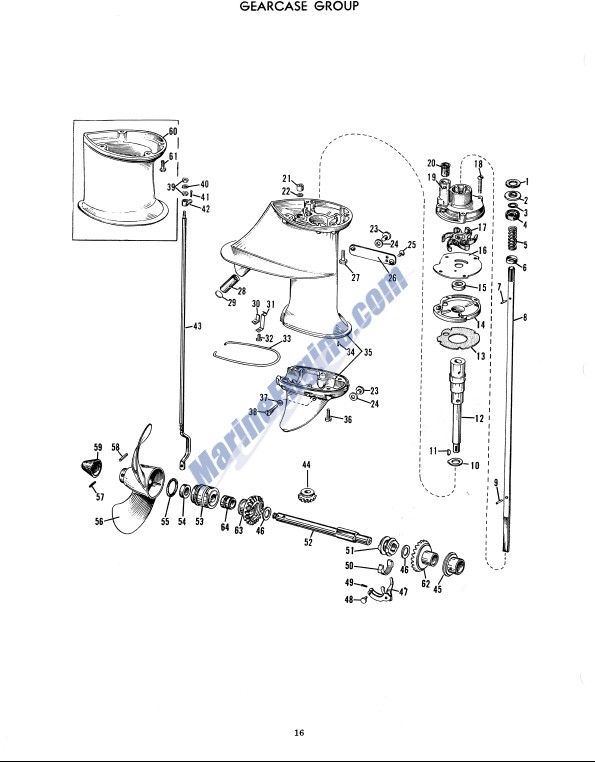

The lower part of the gear case group is all apart, but I’m stumped on how to remove the brass shift rod bushing (part 21 in the accompanying photo, which is OMC part # 303332 @ about $10.99) so that I can replace the shift rod o-ring underneath it (part 22 in the photo, which is OMC part # 301877).

Any suggestions on how to remove that brass shift rod bushing and once removed will it have to be replaced, because of being destroyed upon removal???

Thanks for your help!

February 12, 2017 at 10:11 pm #52894https://www.youtube.com/watch?v=pX1u6rtUE1M

just did my 9.5 Sportwin this way… piece of cake and no need to destroy the brass bushing either 😀

Joining AOMCI has priviledges 🙂

1 user thanked author for this post.

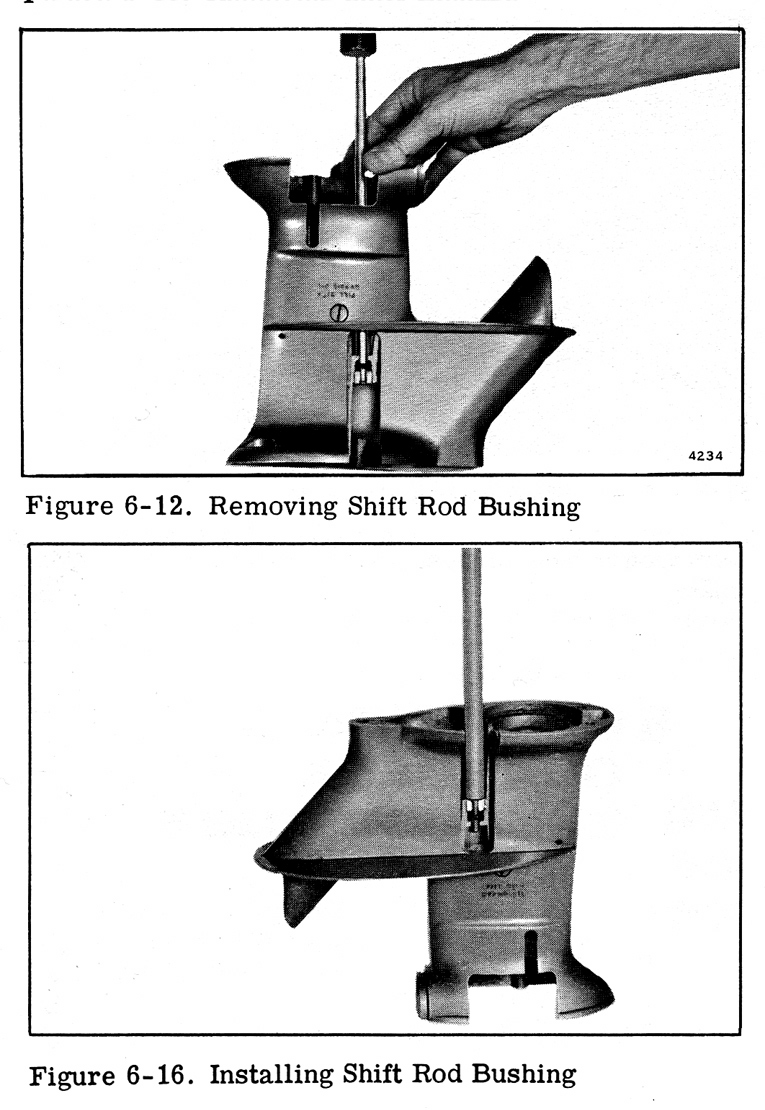

February 12, 2017 at 10:39 pm #52895You do not need to tap all the way through. Just enough to thread a bolt in a turn or so. Then tap against the bottom of the bolt with a punch or piece of 1/4" rod.

I use a 5/16" tap and bolt.

February 12, 2017 at 10:46 pm #52896tapping the bottom of the bolt probably works but the piece of wood with the hole in it and turning the bolt head with a ratchet works very well and you don’t need 3 hands

Joining AOMCI has priviledges 🙂

February 12, 2017 at 11:51 pm #52897There as another video where i guy just slightly mushroomed a piece of thread that then he could use a block of wood to pull the bushing out without needing to tap the bushing. Not sure if they all can be done that way, but he did it with a 1960 Evinrude i think

February 13, 2017 at 1:15 am #52901OMC had some special tools for that, but because of variations in castings, they didn’t always work. . . 😀

February 13, 2017 at 5:10 am #52922

February 13, 2017 at 5:10 am #52922come to think of it…

those bolts that mushroom in cement holes to hold on ….. could probably be slipped inside the brass fitting and…. mushroomed a bit with a few turns then pulled out ?? 💡 no tap & thread needed

I’ll have to try that next time if nobody tried it yet ❓

Joining AOMCI has priviledges 🙂

February 13, 2017 at 3:54 pm #52937quote crosbyman:come to think of it…those bolts that mushroom in cement holes to hold on ….. could probably be slipped inside the brass fitting and…. mushroomed a bit with a few turns then pulled out ?? 💡 no tap & thread needed

I’ll have to try that next time if nobody tried it yet ❓

If you try this be VERY careful to not damage the casting. The very reason the OMC special tool doesn’t always work is because sometimes the hole in the casting is so close in diameter to the hole in the bushing there isn’t enough clearance for the tool to pass thru the casting with enough shoulder to catch the bushing to drive it out. In this case you either take a slight shaving off the hole in the casting or break a sizeable chunk out of it. It is entirely possible to damage the upper gearcase housing toothed point of making it unusable. I made the remover tool myself and have had to reduce the shoulder diameter twice to keep from damaging the casting. At this point the shoulder is barely there. The tool still works but I’m always careful to make sure I have clearance. I can’t remove any more shoulder and still reliably remove the bushing. If it’s that close I use the tap and bolt method.

-BenOldJohnnyRude on YouTube

February 13, 2017 at 8:32 pm #52955This topic inspired me to do the first lower unit reseal I have ever done.

It was on a QD-24 and I just went ahead and used the tap method. There is no way a mushroomed bolt would have worked. It was super easy to tap and put a bolt halfway through and tap with a long punch from the other side.

I reused the bushing as I only tapped half way through. Hopefully that is the correct thing to do:/ but I didn’t have another bushing

February 13, 2017 at 9:14 pm #52958Thanks for the replies, fellows!!!

For $5 I bought a tap, bolt, nut and washer and successfully pulled the brass bushing and re-seated it with a new shift rod seal o-ring. Now, before I fully re-assemble the gear case to the rest of the motor, I’ll add some gear oil and check for any leaks. If all goes well I’ll put it all back together.Thanks again!!!

-

AuthorPosts

- You must be logged in to reply to this topic.