Home › Forum › Ask A Member › Condensers Testing

- This topic has 25 replies, 10 voices, and was last updated 8 years, 3 months ago by

cajuncook1.

-

AuthorPosts

-

January 7, 2017 at 9:38 pm #6063

Hello All,

This is my first post though I have been reading and learning a lot.I recently acquired an 1950 Engin 5 hp outboard which I’m trying to put back in service. I found the gas tank, fuel line and carburetor totally gunked up.

I cleaned the tank and the fuel line and rebuilt the carb. I also replaced the spark plug wires which were in bad shape and reset the points. I tried to start her but no-go. I don’t seem to be getting spark. I tested the coils first by testing the continuity of the primary and secondary winding and they were good. I then moved on to the condensers.

I pulled the condensers out and put an ohmmeter on the condenser and got only a small movement of the needle. I then switched it to the DC volts scale and got very little movement. I switched to a digital meter and did the same tests. I placed the negative lead to the case and the positive to the post. I saw a momentary jump to 1561 and then back to 1. I then switch the meter to the 20 VDC scale and I saw only 0.11 V that dropped off to zero. That sure didn’t seem like enough to fire a spark plug so, I assumed my no-spark condition was the result of bad condensers and order 2 new ones.

Well, the new ones came today, and guess what? I’ve got the same readings. I’m thinking the likelihood that 4 condensers all being bad is unlikely. I think I just bought a spare set of condensers.

So, am I testing these correctly? If not, how do I test them? Is what I’m seeing good or bad? If its not the coils and not the condensers, what’s the likelihood its the magnets? When I touch a screwdriver to the magnet, there’s a pull but how much is needed I don’t know.

Any advice would be appreciated.

RayJanuary 7, 2017 at 10:49 pm #50580There is nothing wrong with your test or the result. The meter jump is due to the electricity from the battery in your tester flowing into and charging the condenser. Once the condenser is charged to battery voltage, the electricity stops flowing and the meter drops back. So, your test is a rudimentary test to see if the condenser can take a charge, and it is. I say rudimentary because it doesn’t tell you what the actual capacitance of the condenser is. And having said that, it really doesn’t matter what the capacitance is, as long as it is reasonably close, when it comes to having spark or not having spark. It is possible in some cases to have some semblance of a spark even if you leave the condenser out. But of course in such a situation, it probably won’t run well, if at all.

I couldn’t help but notice the comment you made about the condenser not having enough voltage to fire a plug (or whatever you said about it). The condenser does not charge up to that kind of voltage.

Back to the question. Virtually all motors made since WWII have Alnico magnets in the magneto. They are virtually indestructible, short of melting them down, so that is not your problem.

I’d say that 99% of no-spark problems are due to dirty or mal-adjusted breaker points, assuming the coils and other parts are good. I’d revisit them.

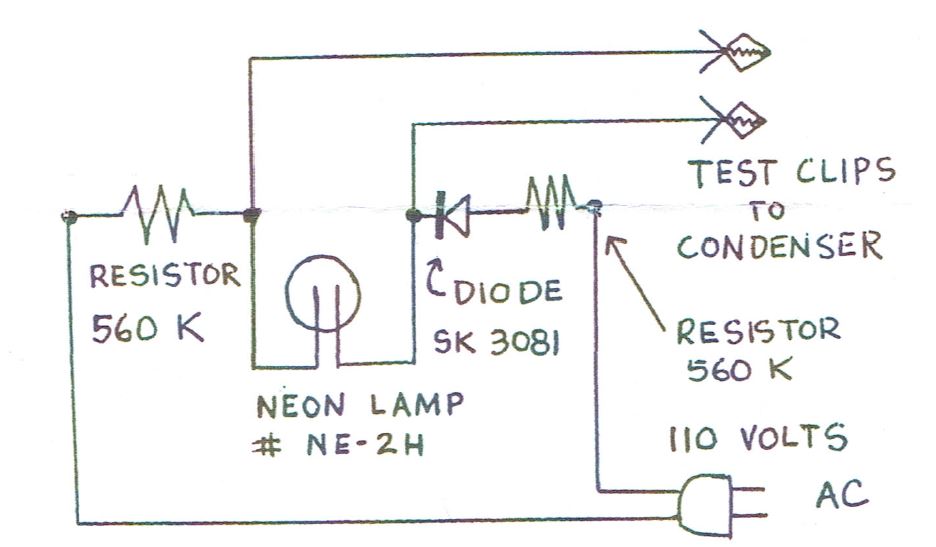

January 7, 2017 at 10:52 pm #50581I made a simple condenser tester using these plans. It actually loads and unloads the condenser, simulating a load. It should have a steady flashing light if everything is working correctly. I’ve had new condensers that failed.

Of course you need to use your best judgement if you make something like this from plans, don’t electrocute yourself or burn your house down……

January 7, 2017 at 10:52 pm #50582Another thought: Can I guess that your motor has a Wico mag with the orange shellac coated coils? Short of physical destruction or roaches eating them, those things are extremely reliable. Be glad you have those, if indeed that is what you do have.

January 7, 2017 at 11:05 pm #50583The tester shown by westwind is the basis for many commercially available condenser testers. It is a step up from what you are doing with the battery in your multimeter. 110V AC is rectified to DC (such as a battery is), which charges the condenser. When the condenser is charged to the firing voltage of the neon light, it flashes, discharging the condenser. Then the process starts over again. The two resistors, together with the capacitance of the condenser, affect the cycle time. Changing the capacitance changes the cycle time, thus it gives a rough or comparitive indication of the capacitance, judging by the flash rate.

January 7, 2017 at 11:24 pm #50585What kind of plug wire did you use?

January 8, 2017 at 12:00 am #50588OK – A condenser (now called a capacitor) is essentially two conductors (like metal foil) separated by an insolator. (Like Saran Wrap) Applied voltage causes electrons to flow on to the plate, but they are blocked by the insolator. At this point the condenser is said to be charged. An analog meter (One with a swinging pointer) measures electricity by how much the pointer(needle) is deflected by the magnetism produced by a coil in the needles base. SO – as you touch the condenser with the analog meter probes, the needle swings until the condenser is charged to the voltage of the meters battery. If it does not return to zero, the insolation is leaking and the condenser is bad. When the probes are removed, a good capacitor (condenser) will hold a charge. Reversing the probes will give a wider swing to the needle because the charged capacitor will add its voltage to the battery voltage in the meter.

Most modern digital meters have a built in capacitor tester. The best choice would be a genuine capacitance tester. . . 😉

January 8, 2017 at 12:13 am #50591

January 8, 2017 at 12:13 am #50591The thing I found interesting with the plug in home made tester is that I found some bad condensers that test good with other methods. I found some that didn’t always flash at a regular rate, indicating some internal failure beginning but not completely failed. In this case, the motor had spark but would not run, making a frustrating investigation.

January 8, 2017 at 12:35 am #50594True, the tester has it’s limitations, but is very useful. If the capacitance is too far off the light may not flash. If there is too much leakage, it may not flash. It is testing at about 100VDC and the condenser may be ok at 100V but break down at 150V. But all in all it is a pretty valid test for what we are using it for.

January 8, 2017 at 2:50 am #50601I remember my uncle showing me how to test condensers buy charging them off a running lawnmower

spark plug. He’d then wait twenty seconds or so, and see if they held a charge

by placing the condenser lead close to it’s case. If it held charge, you’d see

a nice spark! …… not sure how useful that test was, and I haven’t tried it

in thirty years!Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.