Home › Forum › Ask A Member › Drain Plug Assembly installation

- This topic has 10 replies, 4 voices, and was last updated 9 years, 7 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

September 18, 2015 at 11:23 pm #2578

The old 1958 AlumaCraft I just purchased had a crappy plastic

drain plug assembly installed in a 1" hole in the aluminum transom.

It didn’t even have a nut on it…… just threaded into the transom

and sealed with silicone.

I’ve been looking for non plastic alternatives, or make one of my

own on the lathe perhaps.

I found this one on EBay, and now am wondering what kind of

flaring tool a guy would need? I’m only familar with the type

for copper tubing.http://www.ebay.com/itm/Aluminum-Boat-T … 1008483517

Thanks, Buccaneer

Prepare to be boarded!

September 19, 2015 at 1:58 am #24179Bucaneer

Here’s a link to a thread on "Tin Boats" website about how to install those plugs.http://forum.tinboats.net/viewtopic.php … drain+plug

Good Luck with it.

Steve A W

Member of the MOB chapter.

I live in Northwest IndianaSeptember 19, 2015 at 2:31 am #24181Seek and ye shall receive……. Thanks Steve!

Found the photo of the actual Installation / Flare tool.

Think I could make one on the lathe and save $30.

If you can’t see the photo, here’s one on EBay…..

http://www.ebay.com/sch/i.html?_from=R4 … 0&_sacat=0Prepare to be boarded!

September 19, 2015 at 2:33 am #24182You have the lathe so you can make the tool!

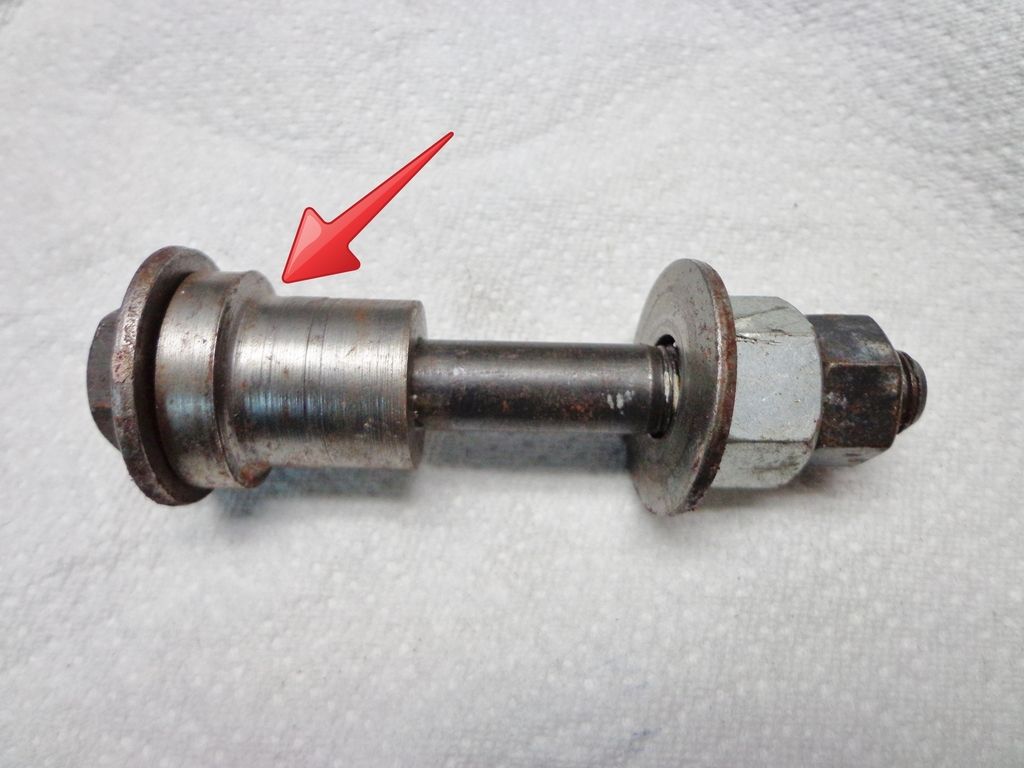

Here’s one I made for flaring the end of the brass drain tubes. It’s hard to see in the pic but there’s a round shoulder by the red arrow which folds the end over. The new tube will need trimming to length and a good coating of Sikaflex on everything will keep water out of the transom.

September 19, 2015 at 2:49 am #24184

September 19, 2015 at 2:49 am #24184Mumbles, you’re correct…… I can’t see a rounded shoulder!

So now I’m thinking…… (dangerous, I know) can I make

the tubing, bushings, etc., and save another $15?

Where would I get a chunk of the correct OD / ID tubing

in brass or aluminum?

Thanks!Prepare to be boarded!

September 19, 2015 at 2:58 am #24186I used to buy the proper drain tubes at my dealer. Along with being the correct diameter for a common rubber plug, they were quite reasonably priced and were already preformed on one end. I’ll see if I can find them anywhere online.

September 19, 2015 at 3:00 am #24187OR use a ball peen hammer set into the tube and tap with another hammer. have someone hold a hard wood block on the flared side. just a thought.

September 19, 2015 at 3:11 am #24188If you scroll down a little bit in the following link you will see the brass ones I’m referring to.

http://www.marine-products.com/parts/bo … g.html?p=3

September 19, 2015 at 1:06 pm #24201By using a brass tube in an aluminum boat, would it have any

weird corrosion problems from non similar metals?

$10 bucks for just the brass tube, so perhaps I’ll but the whole

kit for $15

Thanks!Prepare to be boarded!

September 24, 2015 at 2:30 am #24486I received my drain plug tube installation kit today,

and so far made the one (blue) "Fitted Flange Fixture"

on the lathe with a radius that fits the pre-flared

end of the tube.

Instruction card shows the other (blue) "Sloped Flange Fixture"

with a healthy bevel.

The store bought flaring tool appears in photos to show both

flange fixtures formed the same.

Do you think the fitting that’s going to flare the end of the tube

can be made the same as the "pre-flared" end?

It comes with an O-ring, but should I use a little

marine silicone for good luck?

Thanks.Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.