Home › Forum › Ask A Member › ELGIN 12 Recoil

- This topic has 12 replies, 5 voices, and was last updated 9 months, 4 weeks ago by

dave-bernard.

dave-bernard.

-

AuthorPosts

-

May 4, 2024 at 3:40 pm #287564

- Stuck on rewinding the spring without a “ special tool””

- I got an Elgin 12 ( (1955) running and pumping but it came with no pull cord. I loosened the recoil screws enough to tilt it forward and thread a new cord without removing the whole thing. All good.

- Took out the drive pin and still good but I can’t figure out a way to wind up the ( good ) spring counterclockwise 8 turns. I threaded a double nutted bolt into the hole and got 3 turns but then the resistance caused my bolt to loosen and not grip the spring anymore.

Any suggestions? - Thanks in advance

- Dave

- My phone put these stupid numbers in / not me

May 4, 2024 at 6:35 pm #287573I remember removing a pin then using a srcewdriver to wind the spring,

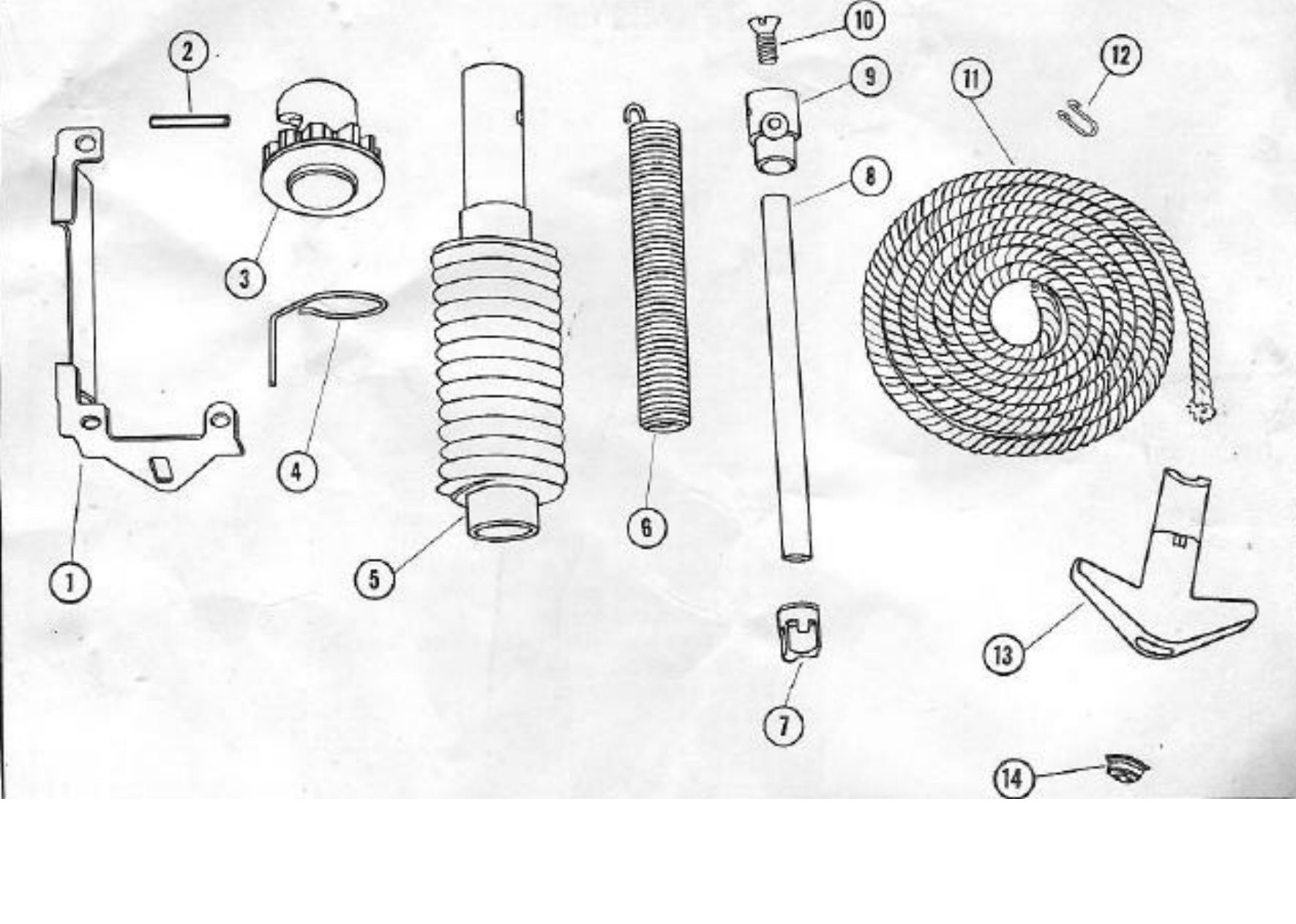

and also remember is was a pain in the you know where!1956-63-West-Bend-12-thru-20-hp-models

Prepare to be boarded!

May 4, 2024 at 6:38 pm #287575May 4, 2024 at 8:21 pm #287579Thanks Buc.

I read about winding it up with a screwdriver, but I don’t see how it’s done. Once you remove that little top screw all that’s facing you is a 1/4 “ threaded hole . That’s why I tried a 1/4” bolt double nutted to try to grab the spring and turn it counterclockwise.May 4, 2024 at 10:19 pm #287590I believe I just turned the screw (that’s in it) with the screwdriver

counter clockwise, but made sure it was good and tight first,

as I remember having a similar problem.Prepare to be boarded!

1 user thanked author for this post.

May 5, 2024 at 9:16 am #287599I used a large prybar screwdriver that had a square shaft and a large adjustable wrench. I also used a quick grip ratchet clamp.

When I replaced the cord on my 1966 Johnson 5 hp, I used a very large screwdriver that had a square shaft on it. I used a large adjustable wrench on the square shaft and turned it while pushing down on the screwdriver handle in that top screw. I needed two people to do the job. While I push down and turned the screwdriver with the wrench, the other person would take a pair of quick grip, ratcheting, squeeze clams and put it around the lower end of the rope drum and clamp it on when I got tired. it held the drum in place until I could get re-situated. He released the clamp and I did another turn or two and the he would reclamp it. Did it several times until it was the proper amount of turns. I installed the rope and tied it all off and released the clamp and at that point, it pulled the cord in and the set up worked perfectly.

1 user thanked author for this post.

May 5, 2024 at 9:18 am #287600May 7, 2024 at 8:59 am #287671Update

The bolt double nutted at the bottom did work after I got it tighter by engaging the pinion on the flywheel and tightening it up against that pressure.The bolt approach has several advantages. First it acts like the “special tool “ in that you can put a socket on the bolt to wind up the spring ( or clamp a small vise grip to the bolt). Much easier to turn than the screwdriver method.BUT, even more importantly, you can use the bolt to move the spring up and down until the drive pin holes align perfectly.So thanks guys for the responses. That issue is solved.Sadly, after all that the recoil will not rewind, even though it wound up ( 8-9 turns counterclockwise) with tension and nothing is binding.I guess that I’ll have to pull out the spring assembly which I’m not happy to do for fear of creating a new problem.Any more thoughts ?May 7, 2024 at 12:09 pm #287674Did you try loosening the mounting bolts to see

if there’s something binding?Prepare to be boarded!

May 8, 2024 at 10:20 pm #287710SUCCESS!

I went back to it ( no binding, but still no recoil) and wound it up 12 turns instead of the 8 recommended . Zing ! Now it recoils like a shot arrow , maybe too well. I might reduce the turns to 10 or 11 just to be safe. But I did notice that the inner hole lined up perfectly with the outer one once I got to the 12th wind up .

I’ve got to say that the 2” bolt ( 1/4-20) double nutted was the handiest tool for this job.

Final comment: I would rather replace a spring on these starters than wind up an OMC horizontal one.

-

AuthorPosts

- You must be logged in to reply to this topic.