Home › Forum › Ask A Member › Elgin Outboard Service Manuals?

- This topic has 10 replies, 5 voices, and was last updated 3 years, 1 month ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

November 8, 2022 at 3:38 pm #268802

Is there such a thing, or does anyone have, an inclusive Elgin shop manual?

I’m working on a

1951 Elgin 7.5 hp, Model 751

Sears Model number 571-58751Currently, I’m wondering how to remove the upper crankshaft roller bearing

from the cartridge, to get at the crankshaft seal, without harming the roller bearing, as it

seems okay. It would be nice to be able to remove the bearing without

ruining the seal, at least until I can get a bore measurement to see if I

can find a replacement seal.I’ve tried heating around the bearing with a propane bottle torch and slamming

down the bearing cartridge on the workbench, but see no movement of the bearing.There appears to be no way to use an inside bearing puller, nor can one get at

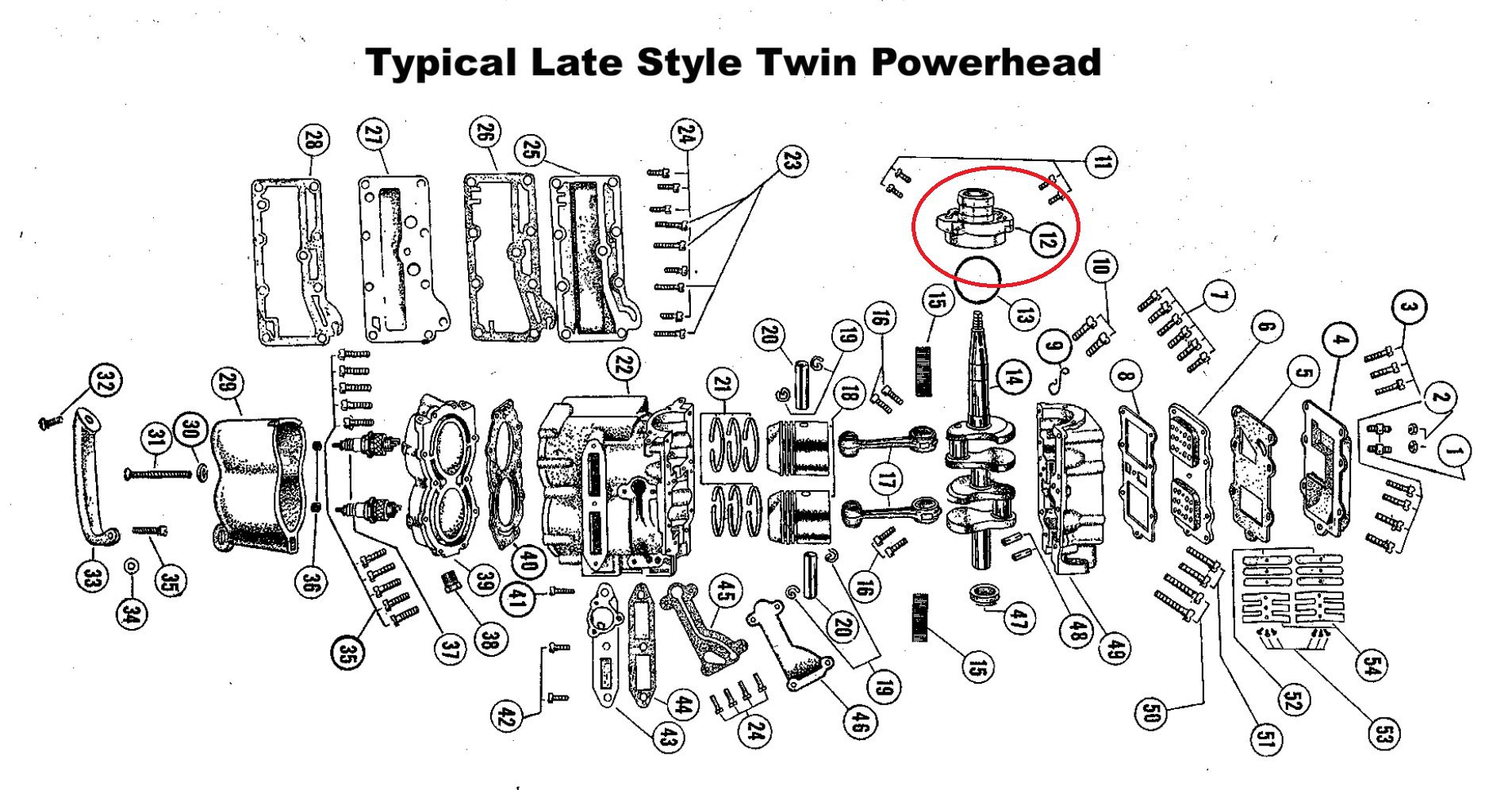

it from atop with a punch.I have a general parts diagram that shows the bearing cap / cartridge, but it appears that it

was sold with the bearing and seal as an assembly, as the later are not shown

separately.Ideas, or a shop manual most welcomed. Thanks.

Prepare to be boarded!

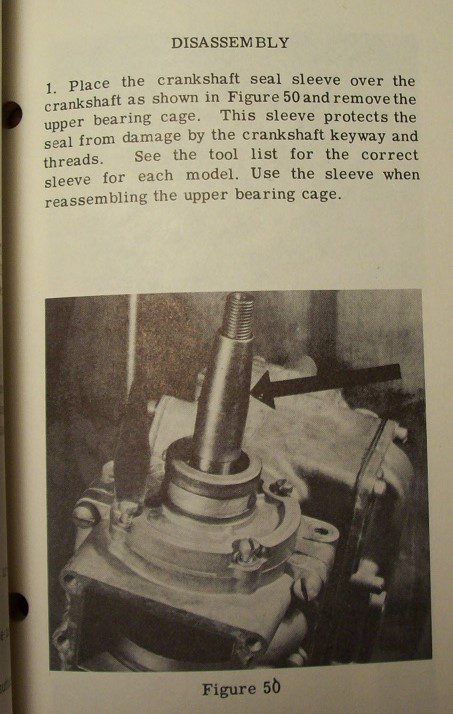

November 8, 2022 at 11:31 pm #268836The service manuals I have don’t mention disassembly or assembly, only how to remove/install as shown here. If the bearing is meant to come out, I would heat it with a propane torch until it starts to smoke, and then drop it squarely onto the end of a short pipe held vertically in a vise. The pipe needs to be the size which gives the bearing a place to go, and put a rag into it to catch the bearing.

Dropping it onto a bench won’t do anything because it appears that the bearing is flush with the cage surface. The bearing needs clear space to drop into. The sleeve tool is part number T-888. If your serial number is below .18286 and your flywheel weighs 4 pounds, you may need the 6.25 pound flywheel if idling is poor.

-

This reply was modified 3 years, 1 month ago by

HARRY D. NICHOLSON.

-

This reply was modified 3 years, 1 month ago by

HARRY D. NICHOLSON.

-

This reply was modified 3 years, 1 month ago by

HARRY D. NICHOLSON.

November 9, 2022 at 5:33 am #268843I would try the heat/support/bang method a few more times, first, maybe trying to let some thin oil or WD-40 wick in between the bearing and the housing, before hand. Then, if that didn’t work, if it were me, I would measure the OD of the bearing and see if it’s bigger than the OD of the mag support part of the casting. If it is, then I would measure exactly where, then drill two holes 180 degrees apart, into the housing from the top, right above the OD of the bearing. Maybe 1/8″ holes. Then the idea would be to heat and support the housing, and use an 1/8″ punch to tap the bearing down, alternating between each hole. If that ended up being successful, then I would tap the holes (8-32?) and install a couple of shallow set screws with Loctite, to permanently close the holes.

This is all speculation, of course. My co-workers tell me I think outside the box. Sometimes it works, sometimes it doesn’t.

Long live American manufacturing!

November 9, 2022 at 9:17 am #268845Harry and Bob, thanks for the interesting replies.

When I heated the bearing cap and slapped it on the workbench,

I did so on the edge of the cap, so the bearing didn’t hit.

Second try, I put the cap over the opened vice jaws

and smacked the cap with a big plastic hammer.

I guess I’ll get more aggressive with the heat and not

worry about the seal.

Interesting about the flywheel weight….. my serial number

is 2750, so out of curiosity, perhaps I’ll weigh my flywheel.Bob, I’ve used your “out of the box” idea for something

similar once, but can’t remember on what……. perhaps

you helped out on that one as well!Thanks!

Prepare to be boarded!

November 9, 2022 at 12:05 pm #268855I got out the big guns torch this morning and had the bearing out

of the case in about 5 minutes. I straddled the bearing with

the vise jaws and got out the big plastic hammer again.

The seal didn’t even go up in flames, but a new one will

be needed. I was able to punch the seal out from above.

The top and bottom seals happen to be the same Garlock 139,

.750 shaft, and 1.250 OD x .320 thick.

Hopefully I can source something that will work.

Still battling one stuck piston ring before the powerhead goes back together.Prepare to be boarded!

November 9, 2022 at 2:23 pm #268862Buc – looking at my National Oil Seals book, their 6835S seal is a close fit at .750 x 1.250 x .312 thick.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."November 9, 2022 at 2:29 pm #268863Well done Buc!…..I like billw’s method……. I think that would work well!

November 9, 2022 at 5:25 pm #268874Buc – looking at my National Oil Seals book, their 6835S seal is a close fit at .750 x 1.250 x .312 thick.

Thanks Bob,

I found some seals by looking on the SKF catalog online, and ordered them this morning,

and they were the same thickness.

They were SKF 7465. I believe that they were advertised as seals for a Ford power steering unit.Prepare to be boarded!

November 9, 2022 at 5:28 pm #268875Well done Buc!…..I like billw’s method……. I think that would work well!

Bobs idea is great, but it would not have worked too good

in this case, due to the size of the hub on the top of the cap

being the same size of the bearing OD below.Prepare to be boarded!

November 9, 2022 at 6:51 pm #268882Buc – looking at my National Oil Seals book, their 6835S seal is a close fit at .750 x 1.250 x .312 thick.

Thanks Bob,

I found some seals by looking on the SKF catalog online, and ordered them this morning,

and they were the same thickness.

They were SKF 7465. I believe that they were advertised as seals for a Ford power steering unit.Buc – OK, good you had another source. I looked up that 7465 seal and found it also fits the power steering pump on a 1963 Studebaker if you need one!

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings." -

This reply was modified 3 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.