Home › Forum › Ask A Member › ELTO Ruddertwin Restoration

- This topic has 31 replies, 6 voices, and was last updated 8 years, 5 months ago by

chris-p.

-

AuthorPosts

-

January 2, 2017 at 4:20 pm #6014

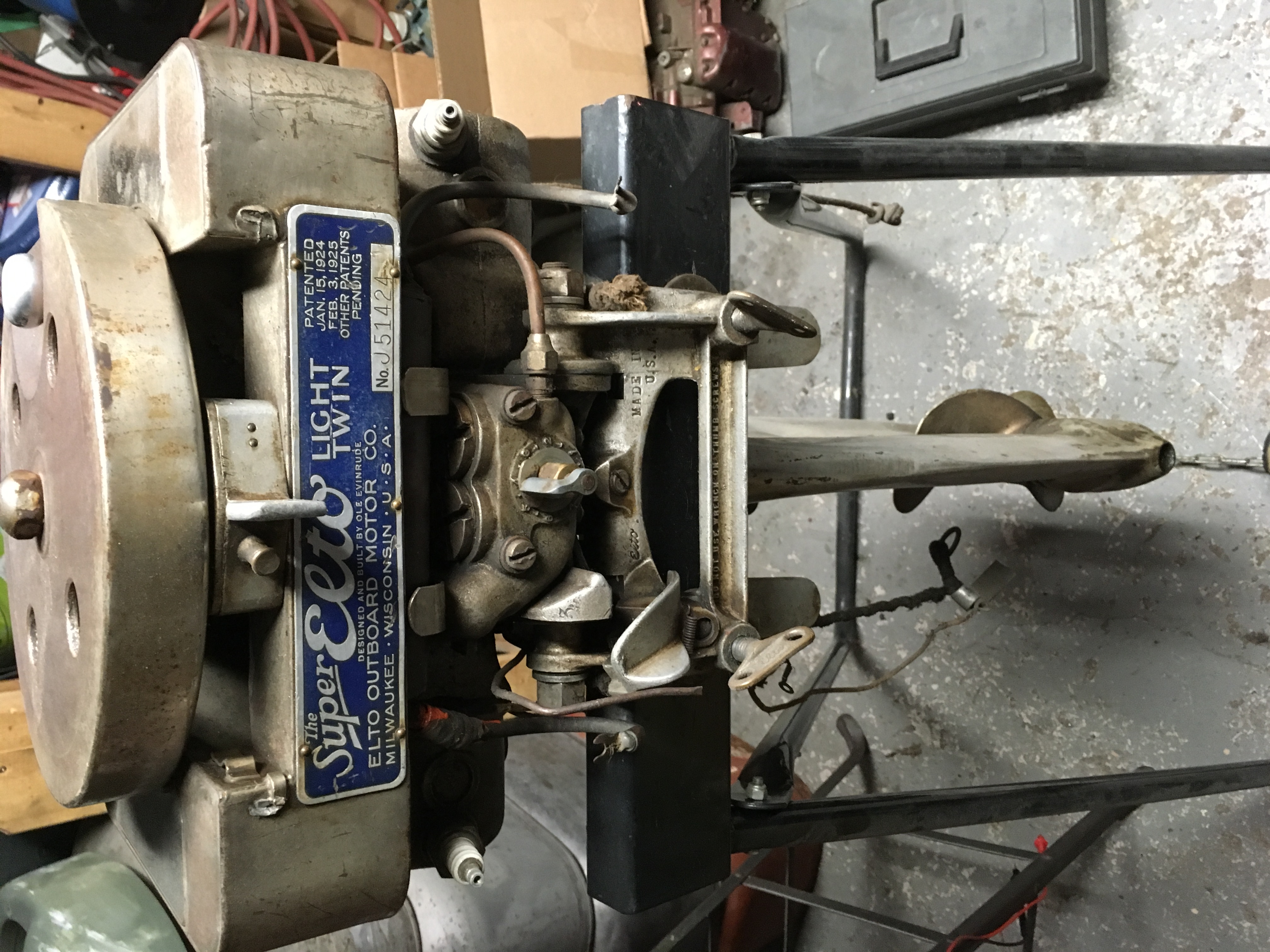

Since Wayne started one of his own, I decided to fast track one of mine as well as I have always been meaning to do it.

The coil tests good, but will at least re wire it.

The timer seems fine, but this is my first Ruddertwin. What do I look for to see if it needs rebuild?

I have good compression and powerhead seems sound. Not afraid to open it up though if you guys that have done one think it is wise? If apart, what should I look at replacing? I like the look of the two tone jugs to crankcase anyways. so may at least pull the jugs to paint/or have plated. If I do, are rings still available for these?

Finally, seems like there are a million and one ways to go about the resto. Curious to hear and see what others have done, as far as what you plated, what you painted, etc…

January 2, 2017 at 4:41 pm #50161I believe the cylinders were nickel plated, not chrome. I think same with flywheel, but most just hard chrome the flywheel… I really do not think there is anything actually painted..the aluminum, looks fabulous with a high polish.

Here is what my cylinders looked like, blow the pic up and you will see, it would not run, both exhaust ports were literally plugged with carbon, all rings were stuck.

I opened it up, removed all carbon, got the rings unstuck, and just put it back together.

It is a very easy motor to start now and mine idles VERY low.Here I am running so early in the year the ice has not left the lake yet…LOL

http://www.richardsoutboardtools.com

classicomctools@gmail.comJanuary 2, 2017 at 7:34 pm #50167Very little carbon build up. Pistons and jugs look to be in great shape. Ill mic them later on. I have the motor totally taken apart now and am cleaning everything as we speak. Im thinking ill nickel plate the flywheel and the jugs. Im not sure on the crankcase and exhaust "Y" yet, perhaps just paint it? What have other done?

January 2, 2017 at 7:40 pm #50168I did nothing, just clean, reassemble and run the snot out of it…

http://www.richardsoutboardtools.com

classicomctools@gmail.comJanuary 2, 2017 at 8:00 pm #50169quote Chris_P:The timer seems fine, but this is my first Ruddertwin.

What do I look for to see if it needs rebuild?Your motor should have a brass bushing so your

timer will likely only need a cleaning.You can get rings here.

http://pistonrings.net/

I have some slide shows on the timer and one way to repair the coil.

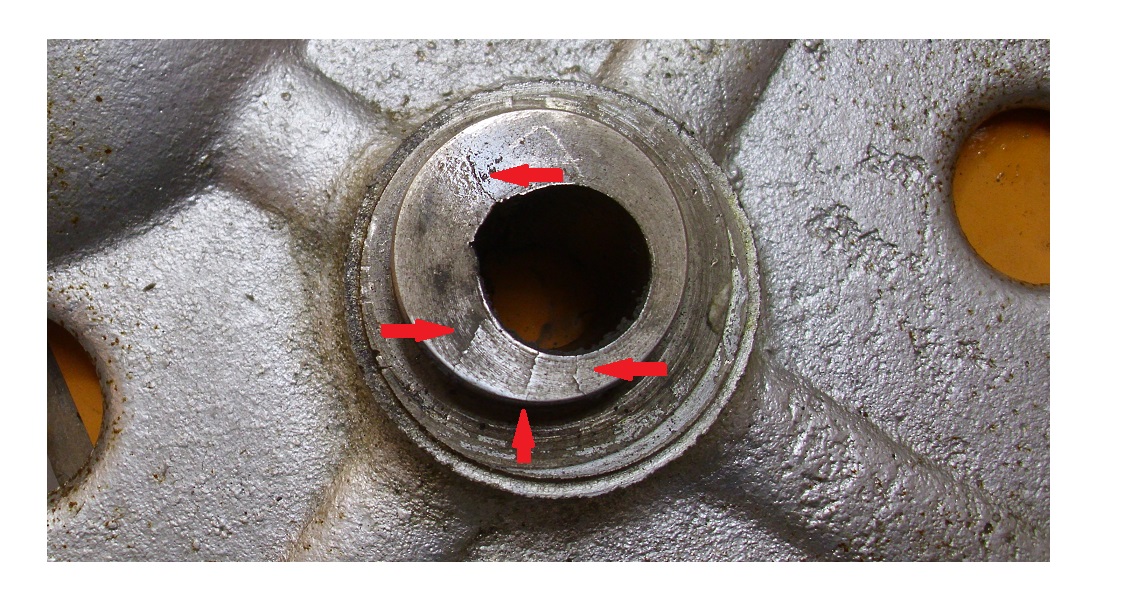

If you haven’t seen them I can send you the links.Check the flywheel for cracks from over tightening.

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

January 2, 2017 at 10:55 pm #50181I would love to see them Tubs, thanks!

I was over at Waynes and his has a small crack similar to what you posted above on his flywheel. Is that common with them?

January 2, 2017 at 11:24 pm #50187January 2, 2017 at 11:24 pm #50188January 3, 2017 at 3:56 pm #50228I’m a bit ahead of you. The one I’m

working on is a really nice motor.

There is hardly a scratch in any of the

aluminum parts and they really are

cleaning up nicely. Even the prop.

But it does have issues. The coil of

course but I have done it already. The

gas tank had some dents. These look to

be intentional rather than accidental to

me. I have gotten the majority of them

out. The tank is still a little low in that

corner and will need a little filler.

I also need one of the water tubes and the

flywheel has been over tightened and it

has cracks. May explain the dents in

the tank. Once I get the gas tank done I’m

kind of stuck till April when I will be able

to get the parts I need. Gives you a chance

to catch up,A soldering gun is all I needed to get the rivets

out of the serial# tag to remove it.Here are the links to repairing the coil and

some information on the timers.https://www.youtube.com/watch?v=e2vxDqF_OEU

https://www.youtube.com/watch?v=zLS6IglCy9k

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

January 3, 2017 at 4:10 pm #50229Tubs……That bench……dam that bench…lol

How can you work in such filth????

http://www.richardsoutboardtools.com

classicomctools@gmail.com -

AuthorPosts

- You must be logged in to reply to this topic.