Home › Forum › Ask A Member › Evinrude 1955 Fastwin throttle sync problem

- This topic has 30 replies, 10 voices, and was last updated 3 years, 10 months ago by

JOHN HOLBIK.

-

AuthorPosts

-

May 8, 2020 at 3:17 pm #202517

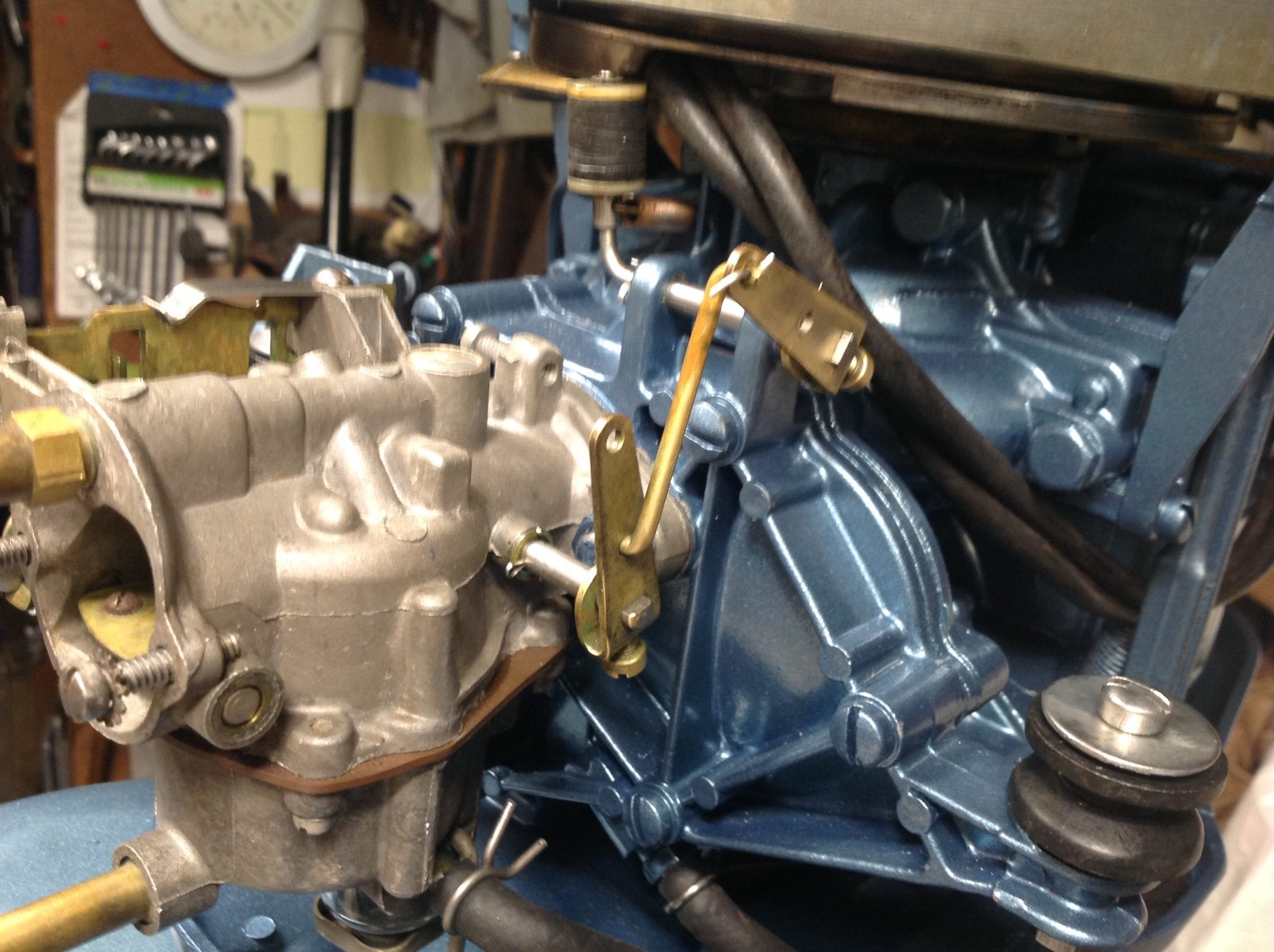

Hi all, just putting the finishing touches on a 15014 Evinrude and am having a problem with the cam follow roller falling off the beginning of the throttle control cam. I have tried every combination possible between the the gears on the motor end, and the gears on the throttle arm to no avail.

The only information I could find on adjustment in the red Johnson service manual was to move the brass control cam forward to make the butterfly open at the correct point, which doesn’t help my problem.Unfortunately it was a parts motor when I started so I don’t know if the problem existed before I started with mismatched parts, although everything seems correct looking at my parts diagram. Help..anyone seen this before?

Thanks,

Bob DMay 8, 2020 at 5:35 pm #202543I think you have this topic posted twice….So, will add more to my reply here…. Do you have the throttle cam synchronization set correctly? Is the carb just starting to open when the line on the cam is bisecting the roller? If the cam is pulled out too far, the roller will definitely hit and jam on the edge of the cam when you advance the throttle from its full retarded/stop position…

Looking at your picture, it kind of looks like the roller is still touching the cam way before the correct pick up point… There is a little line on the cam, this is where the throttle should just begin to open….Yes, I realize there is slop in this linkage, and just because the roller starts to move the linkage, that doesn’t mean the butterfly is starting to open just yet. But, yours looks way over-advanced. Granted, it is tough to tell from that picture, would have to see a picture looking down on the cam roller taken from the front of the engine….In other words, in most cases, the roller should not be actually touching the cam when roller is at the end of the cam….

Again, this may just be a throttle cam/pick up adjustment issue. You mention this engine was built from “parts”, so it may be possible that there is a mismatch of parts, but everything looks “OK” to me also…-

This reply was modified 3 years, 11 months ago by

fleetwin. Reason: addition

May 8, 2020 at 6:24 pm #202552To add a little to fleetwin post. The mark needs to line up with the roller and the pointer needs to line up with start on the tiller handle. Also the choke must be open. (pushed in) Looks like you are a tooth off on the gears.

I love those erude 15’s

dale

May 8, 2020 at 7:11 pm #202553To add a little to fleetwin post. The mark needs to line up with the roller and the pointer needs to line up with start on the tiller handle. Also the choke must be open. (pushed in) Looks like you are a tooth off on the gears.

I love those erude 15’s

dale

“Pointer needs to line up with start on the tiller”? Haven’t heard this one before…. And yes, the throttle gears look one tooth off, but they are off in the direction of not pulling the mag plate back fully….

May 8, 2020 at 7:22 pm #202555If it has not been said, that is gonna be a nice motor….

http://www.richardsoutboardtools.com

classicomctools@gmail.comMay 9, 2020 at 8:21 am #202590If it has not been said, that is gonna be a nice motor….

That is worth repeating for sure….

May 9, 2020 at 9:46 am #202593we want more pictures !!!! cowl and all !!

Joining AOMCI has priviledges 🙂

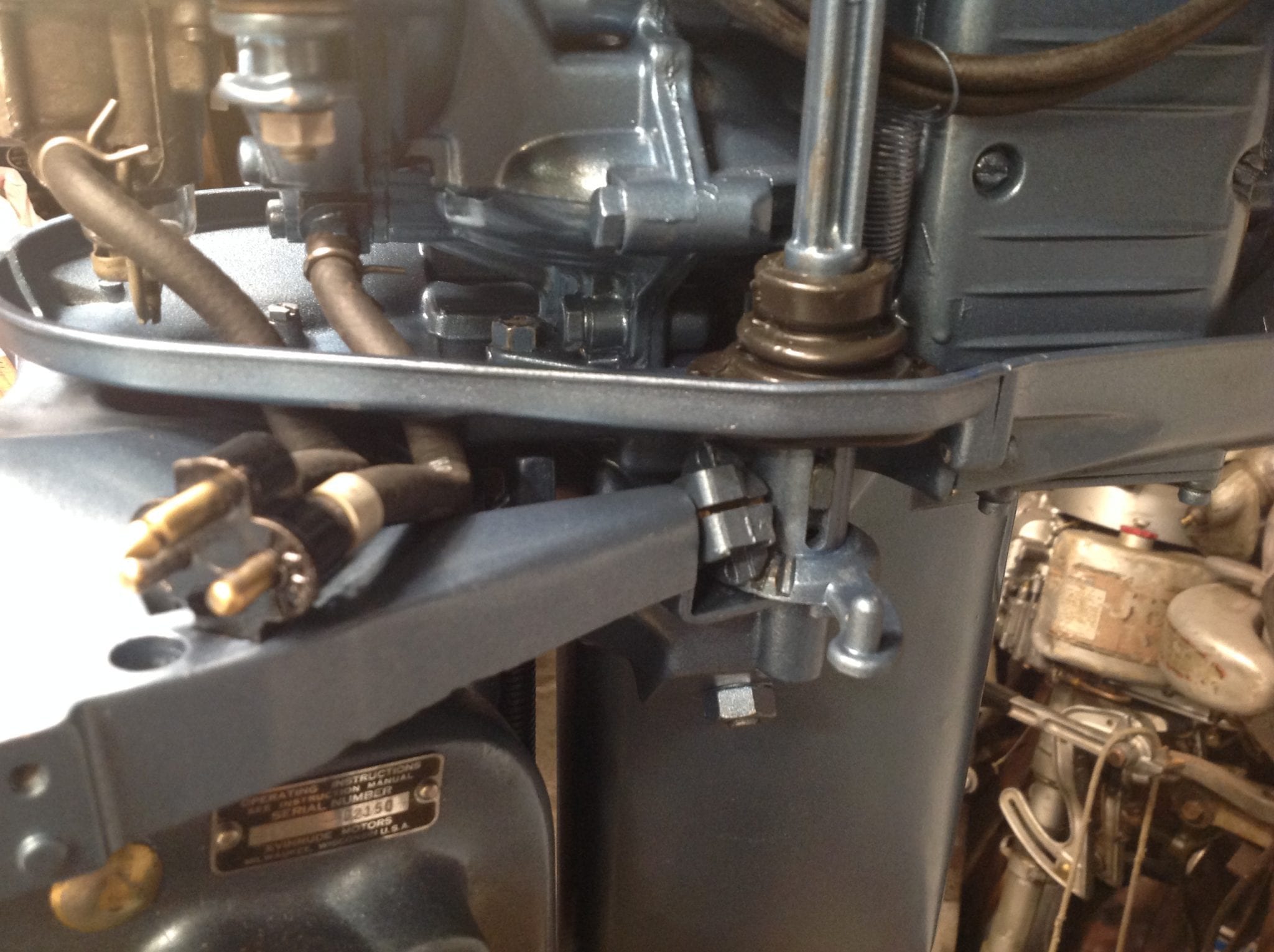

May 9, 2020 at 10:11 am #202608Crosbyman, will shoot some pictures of the cowl (entire motor) when finished. It’s only polychromatic blue right now. Have to add the white contrast and decals.Actually this is the 2nd paint job I did. The first time I shot it with paint from NY Marine. The more I looked at it I didn’t like it. Spraying is the easy part, the prep is the killer. His 58 Evinrude blue was too dark, almost like the 59 golden jubilee blue. Usually Peters paints are spot on? I ended up

using Reprotint, which was a closer match to the original.

Take care,

Bob DMay 9, 2020 at 11:41 am #202618Check the vertical aluminum link that joins the curved flat brass link on the mag. to the lower bevel gear. Your photo demonstrates that it is clearly twisted. Happens when the mag lube gets hardened or some other obstruction keeps mag from rotating easily. You can twist it back to original, just do not use the top arm as leverage. Clamp the I-beam section in an adustable wrench, and using another adjustable on the other end, twist it back to original. Have done it several times with 100% success.

R.TMay 9, 2020 at 6:13 pm #202640Check the vertical aluminum link that joins the curved flat brass link on the mag. to the lower bevel gear. Your photo demonstrates that it is clearly twisted. Happens when the mag lube gets hardened or some other obstruction keeps mag from rotating easily. You can twist it back to original, just do not use the top arm as leverage. Clamp the I-beam section in an adustable wrench, and using another adjustable on the other end, twist it back to original. Have done it several times with 100% success.

R.TWhat are you seeing that indicates the vertical is twisted?

-

This reply was modified 3 years, 11 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.