Home › Forum › Ask A Member › Evinrude 1955 Fastwin throttle sync problem

- This topic has 30 replies, 10 voices, and was last updated 3 years, 10 months ago by

JOHN HOLBIK.

-

AuthorPosts

-

May 10, 2020 at 12:26 pm #202676

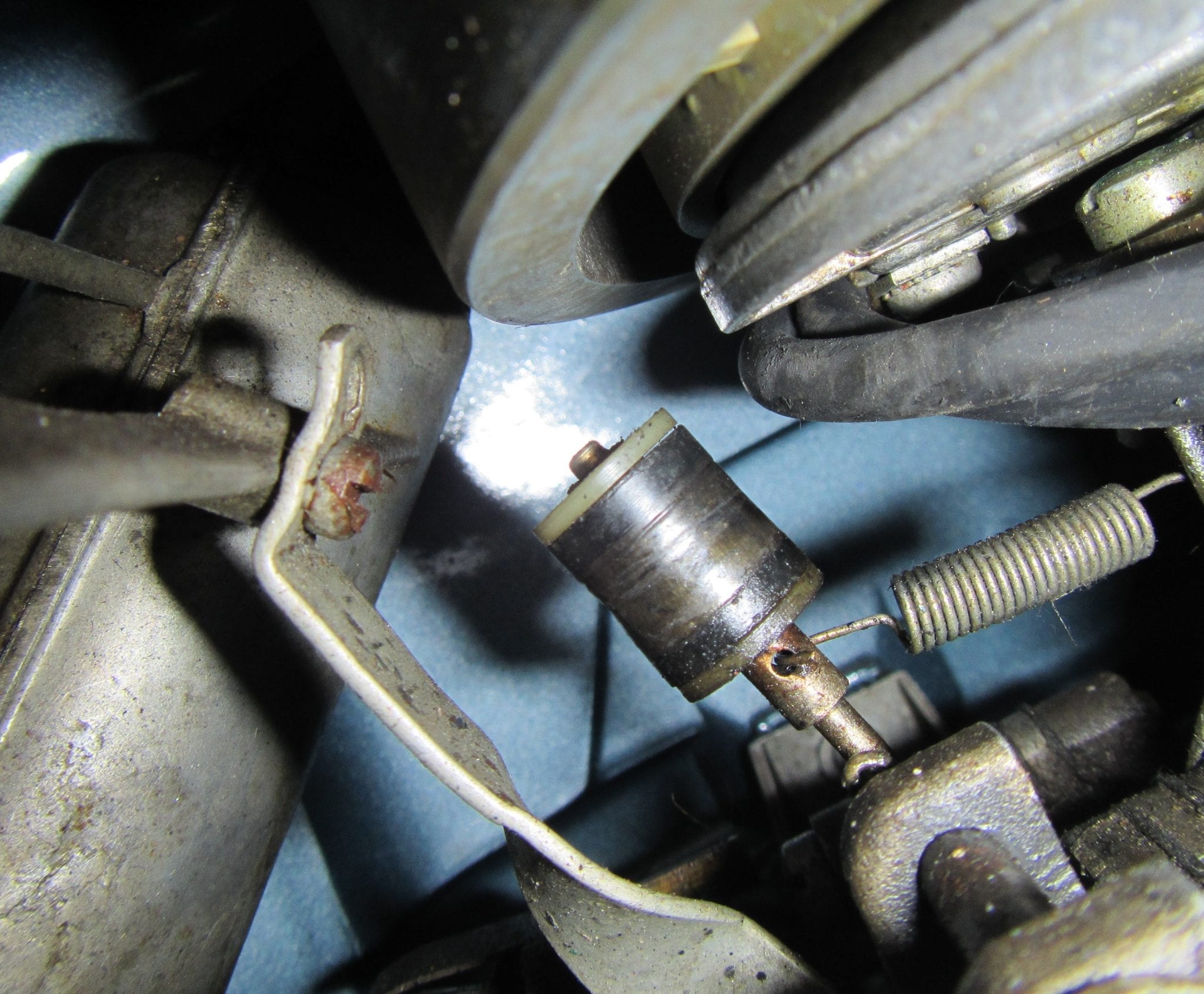

Photo number 3 appears to show a distinct twist in the link. The twist always prevents the brass link from advancing the mag. to it’s intended maximum setting, which results in the mag. not moving far enough to allow the cam to open the carb’s throttle plate.

It’s pretty simple to remove the link, and simply eye-ball it. If it’s twisted, as I believe it is, it’s easy to fix. R.T.May 10, 2020 at 9:43 pm #202731Photo number 3 appears to show a distinct twist in the link. The twist always prevents the brass link from advancing the mag. to it’s intended maximum setting, which results in the mag. not moving far enough to allow the cam to open the carb’s throttle plate.

It’s pretty simple to remove the link, and simply eye-ball it. If it’s twisted, as I believe it is, it’s easy to fix. R.T.OK, help me understand, what about picture number three indicates the vertical link is twisted?

May 11, 2020 at 5:38 am #202748I can’t say that I see a twist, either; but with the stainless clip in place and a 2D photo, I am certainly limited….

Long live American manufacturing!

May 11, 2020 at 11:34 am #202780The portion that is twisted is the vertical I-Beam portion, not the curved horizontal arm. When observing from the top down, it is twisted in a clockwise direction. Like I mentioned earlier, don’t put any force on the horizontal link when straightening. The I-Beam is soft. Twist only on the beam itself. If you don’t believe me, try one from another, functional engine. R.T.

May 11, 2020 at 3:17 pm #202795The portion that is twisted is the vertical I-Beam portion, not the curved horizontal arm. When observing from the top down, it is twisted in a clockwise direction. Like I mentioned earlier, don’t put any force on the horizontal link when straightening. The I-Beam is soft. Twist only on the beam itself. If you don’t believe me, try one from another, functional engine. R.T.

I believe you for sure, just trying to see what you are describing….Are you talking about what appears to be a “twist” right at the bottom of the picture?

May 11, 2020 at 5:05 pm #202810I think I see it now….Son of a gun, I am going to have to start looking for that on other motors…..

Long live American manufacturing!

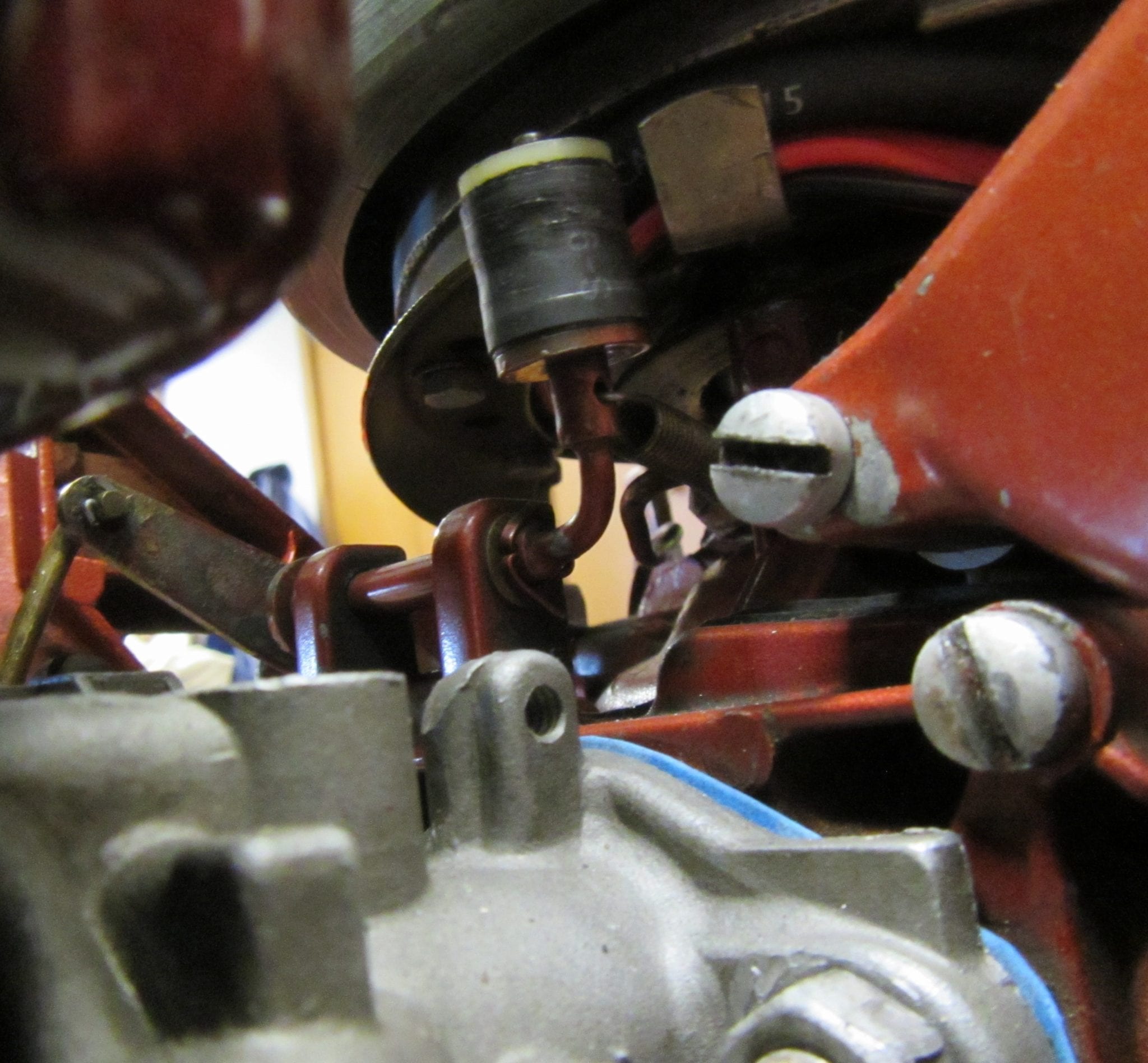

May 11, 2020 at 5:20 pm #202813Bobd getting back to your original question. I went out and looked at my 15 OMC and my18 OMC and both of those motors the roller falls off the ramp just like yours does! I guess I never thought about it. My ’53 it looks like the lever hits the hood when it is moved all the way to stop. Maybe you don’t have a problem after all!

dale

-

This reply was modified 3 years, 11 months ago by

labrador-guy.

labrador-guy.

-

This reply was modified 3 years, 11 months ago by

labrador-guy.

labrador-guy.

May 11, 2020 at 7:56 pm #202837Labrador guy ……nice motor. I can appreciate all of the work that it takes to get one to look like that.

My problem was once the roller fell off the brass cam plate, I couldn’t get it to return in the opposite direction. What was happening was that the adjustment on the cam plate was so far out the roller would get hung up on the return.

Once I adjusted it back towards the flywheel, all was good. Rookie mistake.

Started it for the first time probably in 40 years on Sunday. It ran well but had a small water leak around the exhaust gasket plate. Those were the only gaskets I didn’t replace in the overhaul because the small 10-24 crews always break off in the head……… Well I was right, out of the 9 was able to get 4 out and 5 broke off. Tried welding a nut on to the studs left by the broken screw head, but they were so frozen in the block it just snapped the balance of the screw closer to the head. I’m now going to drill them out and put in Time- Serts.

Bob DMay 11, 2020 at 9:57 pm #202844Yup those exhaust cover bolts can be a bugger for sure! Glad you got it figured out.

May 13, 2020 at 7:53 am #202954Bob-d,

I am going through the same thing on my 1960 18 hp with the broken exhaust bolts. I have 3 that broke and 1 more to drill out. Could you let me know which timeserts you use, and where you get them.

Thanks Jeff

1954 Evinrude 7.5 HP

1954 Evinrude 15 HP

1954 Gale 12 HP

1956 Gale 12 HP

1956 Evinrude 5.5 HP

1960 Evinrude 18 HP

1973 Johnson 6 HP-

This reply was modified 3 years, 11 months ago by

crowsbeak.

-

This reply was modified 3 years, 11 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.