Home › Forum › Ask A Member › Evinrude 3 hp Lightwin 3012 diagnosis

- This topic has 23 replies, 8 voices, and was last updated 7 years, 7 months ago by

fleetwin.

-

AuthorPosts

-

June 10, 2017 at 5:50 pm #7292

Just fired up the lightwin that I traded for a little Johnson Iron Horse engine.

Installed new coils, and a partial carb kit, new impeller, etc.

Seems to run well from Start to Fast, but when the mag lever goes

any less that half way, it abruptly quits.

When I got it, I check compression and had 77 & 79 psi compression,

so assumed it would be a good idler.

I’ve tried adjusting the low speed needle anywhere from 1/2 to 1-1/2

turns open, and it still abruptly quits.

It appears to be "fuel" related, as one time I choked it partially

and was able to go further towards "slow".

When it quits, I have to choke it to restart.

It runs okay at full throttle, so I believe the sintered fuel filter in

the tank is okay.

I pulled the expansion plug on the carb and the three little

holes for idling were open. The carb got a new needle and seat,

float, & needle packing, from a partial kit that I had.

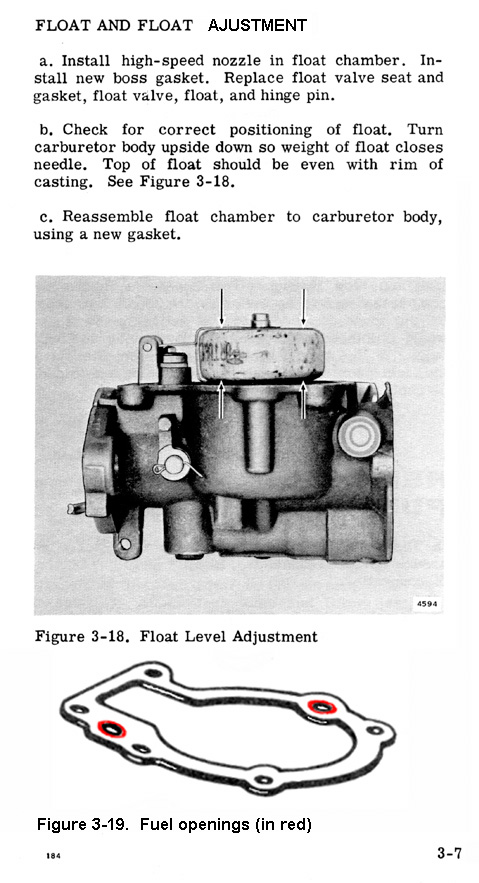

I made a new high speed nozzle "boss" gasket out of leather,

which appeared to be the correct thickness when I screwed the

carb bowl on.

I synced the mag to carb per the manual.

I did not remove the reed block for inspection.

I did not have any new J6C plugs on hand, so I’m

temporarily installed some J8C plugs.I’ll probably pull the carb back off later today, but just

wondering what the "best guess" of the problem?

Video of it running.

https://youtu.be/mdwmo269at4

Thanks for your sage advice!Prepare to be boarded!

June 10, 2017 at 7:14 pm #59418Update, I pulled the carb back off and checked the reed block.

The reeds were seated, and not cracked.

Took the carb back apart, and remembered one issue that

I had with it originally, when I tried to remove the "high speed"

nozzle. It will NOT budge. Originally I even used a little

propane bottle torch to heat around the nozzle and it

would not move. If I would have tried any harder I’m sure

that I would have snapped it off. I refrained from using a

vice grips.

It runs "fast" okay, so I assume the high speed nozzle isn’t plugged.

Is the "low speed" circuit sharing the high speed nozzle some how,

or is the "low speed circuit" sucking gas from the bowl via the

hole in the castings on the port side of the carb?

Are the two holes in the front of the carb "bowl vents".

I can’t find a good diagram that shows the high and low speed

circuits.

My homemade leather high speed nozzle boss gasket looked like

it was sealing. Opened a new carb kit that I got yesterday,

and it has no such gasket in it, but shows needing it on the diagram

included !

I had previously replace the old cork float with the one in the photo.

The carb wasn’t flooding, so I guess it should be okay… right?So, I guess I’m wondering if the high speed nozzle really needs to

come out somehow, or if anyone has "ideas"?Prepare to be boarded!

June 10, 2017 at 9:03 pm #59424I I would try to remove the high speed nozzle for cleaning. Let it soak for awhile with liquid wrench , then warm it up a little. find (or make) a screwdriver that fits the slot closely and wiggle it back and forth gently ’till it breaks free. That brass is pretty soft .

That float looks good. Did you adjust the height at all ?, your homemade boss gasket looks ok too . The bowl gasket could use replacing, but probably is fine unless attacked by ethanol .

I used to have a cheapo harbour freight ultrasonic cleaner that I used to clean carbs, but it failed eventually, and hasn’t been replaced. It worked pretty good for a while.

June 10, 2017 at 9:30 pm #59425Many prefer the closed foam core float as it is supposed to be impervious to alcohol. The hole in the gasket opposite the inlet fuel hole is the pickup for the idle fuel adjustment. The transfer hole across the top is plugged by a small lead shot. If the shot is driven in too far, it will restrict the fuel. If the hole in the bowl gasket is too small, it will restrict the fuel. If the shot is missing, the idle circuit cannot draw up the fuel. They will not idle well if the bug screen between the air silencer and the carburetor is left out. . . 🙂

June 10, 2017 at 9:39 pm #59426

June 10, 2017 at 9:39 pm #59426Wedgie, I soaked the carb overnight in OMC tuner. It

seems to work pretty good. I’d be more inclined to

try the torch and penetrating oil on the high speed

nozzle again (and may yet) if I find out it has

affect on the low speed circuit.

Seems like in the good old days there were diagrams

that shows the fuel flow / circuits. I try to figure

them out myself, to see how they work, but I think I’d need an x-ray machine

for this one!

The old carb gasket is the rubber type and seems okay.

The one in the carb kit is a fiber gasket, which I suppose

would work okay too.

I used a ultrasonic cleaner at work years ago to clean my

watch band….. worked great and the band was tighter

after from getting all the crud out.

ThanksPrepare to be boarded!

June 10, 2017 at 9:47 pm #59428Garry, thanks for verifying that the other hole

in the carb body is for the idle circuit.

I believe the lead shot is in place, but will

look again. Am I likely to bugger up the carb

if I try removing the lead shot and rodding

out the passage?

The "bug screen" / flame arrestor or whatever it

is, "was" installed.

I did adjust the float so it was "level" when

upside down.

I never use "gasohol" in my two cycle engines.

So far the non-oxygenated is available in my

neck of the woods.

Back to the garage! Thanks!Prepare to be boarded!

June 10, 2017 at 10:26 pm #59429Any slop in the main bearings?

June 10, 2017 at 11:38 pm #59435Well, I thought I had it cured. I probed the low speed

circuit (that Garry ID’d) with a wire. It went in easy

until it dead ended in an inch and half or so.

My WD-40 wand fit nicely in the hole, so I sprayed

in there while holding the throttle plate open and

observing. First shot most of the spray backed up

around my wand. I kept spraying and observing

until I determined I had good flow thru the three

little holes by the throttle plate.

Also did some measuring on the carb halves trying

to determine exactly how thick the nozzle "boss"

gasket needs to be. Determined anything thicker

than 1/8" would start to compress the washer

when the carb is bolted together. I added a fiber

shim behind my leather washer.

Also swapped out the old carb body "rubbery"

gasket for the new fiber one.

Installed carb back on, leaving the silencer off.

Started right up, re-tuned the high speed.

Enrichened the low speed jet some and got

it to idle like a Swiss watch. Probably the slowest

idling outboard I have with the exception of my

Chris Craft.

Went inside leaving it idling to get my camera to

show the world. Still idling great ten minutes later.

Shut it down to put the silencer and cowlings back on

so it would be more "photographic".

Started it up, re-tuned the high speed just a tad.

Slowed down to half throttle and started the "Dying"

gag again, but choked it and it came back.

Enrichened the low speed needle some more

(which didn’t make sense after putting the silencer

and screen back on….. would have thought it would

need "leaning" out. Started to die, so I choked it,

but stopped. Tried restarting it, but it I may have

flooded it. Pulled until my shoulder and wrist

felt like rubber. Decided to go inside and check

out the chocolate chip cookies in the oven.

I’d pull my hair out, but don’t have much left. 😯

P.S.- I don’t remember any play in the crank bearings,

but then again, don’t remember actually checking them!Prepare to be boarded!

June 11, 2017 at 12:31 am #59439The intake/silencer has a nylon plug right in the front. I had one fall out on the ground at my test tank, and the motor would not run properly without it. Just another thing to check.

June 11, 2017 at 1:23 am #59442Aquasonic, I don’t remember seeing a nylon plug

in the breather, nor a "hole" where one would have

been, but will look tomorrow. I had it running

great with the breather off period. Hopefully

the dawn of the day tomorrow will shed new

light on the problem….. and remedy!Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.