Home › Forum › Ask A Member › Evinrude 3602E (folding lower unit) lower unit removal.

- This topic has 12 replies, 4 voices, and was last updated 1 year, 4 months ago by

fleetwin.

-

AuthorPosts

-

September 25, 2023 at 5:06 pm #280999

Hello all,

I’m working on a 1965 Evinrude lightwin 3602E (folding lower unit). I’m trying to remove the lower unit from the power head. I took the 4 bolts off that fasten the lower unit to the bottom of the power head. I can’t seem to remove the lower unit. The upper drive shaft won’t seem to come out of the power head. Is there something else holding the drive shaft in place? I looked on the lower unit diagram (from marineengine.com) and it seems that there are 2 “roll pins” on the shaft? They are #45 on the diagram. I’m unfamiliar with this part. Is this what’s preventing me from removing the shaft? I read on marineengine.com’s forum somebody else was having the exact same problem but there was no answer. I also tried to remove the main pin at the bottom of the shaft (the pin that mates with the coupler on the lower folding portion of the lower unit). This pin is #51 on the diagram. But, I couldn’t get that to budge either. The lower unit would slide off that way too. (The shaft would still be in the power head). Is this pin removable? If so, is there a good way off getting it out? I couldn’t get a good angle with a punch. Any help is greatly appreciated.

Thank you,

Todd

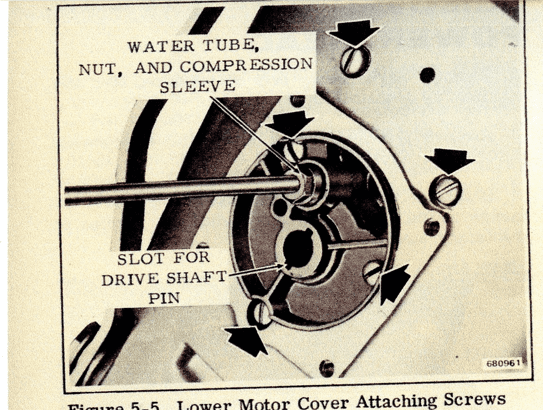

September 25, 2023 at 5:46 pm #281002Are you trying to remove the powerhead or are you trying to remove the lower unit from the hinge part? To remove the powerhead from the exhaust housing, there is a pin through the upper drive shaft that must come down through a slot in the lower motor cover. Slowly rotate the flywheel while lifting the powerhead till the pin aligns with the slot and it should come apart.

September 25, 2023 at 6:14 pm #281004Hello,

I’m trying to get the whole lower unit off of the powerhead. The powerhead is seized so I’m unable to turn the flywheel. I was thinking about putting spare powerhead on it that I have. Does the bottom pin in the shaft come out? ( the one that mates with the coupler on the lower drive shaft, right at the folding portion; #51 in the diagram I included). If I got that out of the shaft, the lower unit could slide off downwards (I think). The drive shaft would still be in the powerhead though. Then could I access the roll pin through through the bottom of the powerhead to get the shaft off?

Thanks,

Todd

September 25, 2023 at 7:52 pm #281017Sorry, if I ever had one with that situation (frozen powerhead), it was too many years and too many tears ago and I just don’t remember. It would appear that the pin should be able to be knocked out, since it is listed as a separate part. The manual shows it being driven out with a punch, supported by a home made fixture. Not a clear picture though.

September 26, 2023 at 9:22 am #281031OK, so you are trying to get the powerhead off the midsection/exhaust housing then… Like Frank says, the upper roll pin in the driveshaft must be aligned with the slot in the exhaust housing first. I’m assuming that the gearcase is off already.

For the sake of clarity, let’s just assume the the upper driveshaft splines are seized/rusted into the crank.

The next question is whether or not the upper driveshaft will pull out from the midsection upwards. I realize it is retained/pinned so that is won’t fall down and out of the engine when the gearcase is removed. Just wondering if there is some sort of bushing in the exhaust hsg that will prevent the upper driveshaft along with its pins/couplings to be pulled up and out with the powerhead… Don’t have one in front of me, but do have one at home…

Which powerhead screws did you remove? The several screws around the outer edge of the powerhead, or the four bolts that secure the powerhead adapter to the exhaust housing? I would remove the four bolts so the powerhead and adapter come off as an assembly, this will keep the upper roll pin from holding the driveshaft in place. Once all those screws are out, does the powerhead even attempt to move upwards at all?

September 26, 2023 at 2:30 pm #281043if the ph is seized it may be stuck rings like my 9622a 9,5hp

pull the cyl head and soak in some release agent of your choice wait a few days and try strong taps * on the pistons … alternating and resoaking it may work loose.

*use a large wood peg 12 inchesx 1 inch to wack the pistons .

Joining AOMCI has priviledges 🙂

1 user thanked author for this post.

September 29, 2023 at 7:31 am #281102Hello,

Thank you for all the advice! I was actually able to free the power head and get the shaft out of the powerhead by aligning the slot as you suggested. But, I also made a VERY silly mistake in the process. I had a momentary lapse of reason. This might be hard to explain. This happened before I read you message about aligning the roll pin to release it from the powerhead. So, the motor was secured on my boat transom in the vertical (running) position. I had taken the four bolts out that fasten the powerhead and lower unit together. I couldn’t figure out was holding the two together. I kept pulling up on the powerhead but it wouldn’t come free. Without thinking, I flipped the motor “up” (like you would to get the prop out of the water) to look up the lower unit where it folds. When I did this, the powerhead shifted down about an inch or more putting a lot of lateral force on the driveshaft. The top of the shaft was actually resting on the exhaust housing. I could see the shaft was bending under the weight. I carefully flipped the motor up the the vertical position. When the load was off the shaft, it seems to have returned to its original shape (straight). But I’m worried that there might be a slight bend in the drive shaft now. I actually tried for two days to get the bottom pin out so I could remove the shaft from the housing. No luck though. Been using penetrating oil, heat, a short handle sledge and a punch. Can’t seem to get it out. It’s not budging at all. If I could get it out, I could remove the other two roll pins on the shaft and roll the shaft on a flat surface to see how bad it is bent (if any). I’m thinking now I might leave it “as is” and see what happens when I get it running. Thought on this?

Thank you,

Todd

September 29, 2023 at 8:02 am #281103don’t fix it if it works…

Joining AOMCI has priviledges 🙂

September 29, 2023 at 12:12 pm #281107I seriously doubt that you bent the shaft that easily.

September 29, 2023 at 4:17 pm #281110Hello,

Sorry for the late response. I was able to get the drive shaft out of the powerhead. The motor was seized but I was able to free it after a couple days of letting some penetrating oil soak in the cylinders. Then I was able to pull the shaft out of the powerhead by aligning the roll pin in the slot like I was taught how to in this thread. But, before I knew how to get the shaft out, I might have bent the shaft?? Made a stupid mistake ( I told Frank about it in this thread). But I pretty sure it’s fine. Thank you for the advice!!

Best,

Todd

-

AuthorPosts

- You must be logged in to reply to this topic.