Home › Forum › Ask A Member › Evinrude Speeditwin 22.5 starting instructions

- This topic has 12 replies, 5 voices, and was last updated 7 years, 9 months ago by

bsplit.

-

AuthorPosts

-

March 30, 2017 at 1:33 pm #6641

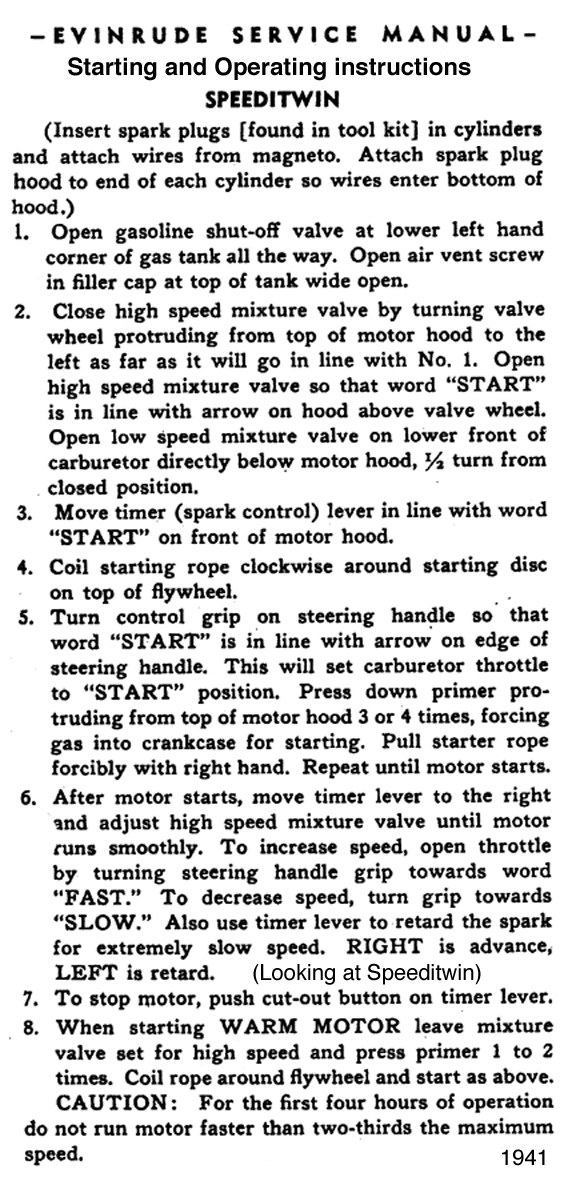

I picked up a Speeditwin at Mark Suter’s meet last fall, and just got it running after cleaning the carb, and replacing the condenser. However, the instruction decal on top of the tank is toast. Does anyone have a picture of the decal?

Thanks,

JimMarch 30, 2017 at 11:07 pm #55225Here you go . . . 😉

March 31, 2017 at 12:01 am #55227

March 31, 2017 at 12:01 am #55227P S . . .

Many find the shear size of this antique intimidating. Just pulling on the rope to turn it over can take considerable effort, However both cylinders going on compression at the same time also means you have almost 40 degrees at the bottom of the cycle when the ports are open and the outboard turns freely. So, the starting technique is to wrap the rope around the rope sheave so that turning it counter clockwise gives you about four inches of free rope. This gives you the ability to bounce the flywheel back and forth at the bottom of the stroke. Timing the force of your pull to the clockwise bounce of the flywheel will give you the added energy to easily crank the motor. . . 😉

March 31, 2017 at 3:46 am #55244

March 31, 2017 at 3:46 am #55244As always……thanks a lot for your help, Garry

Jim

March 31, 2017 at 12:14 pm #55253Based on advise from Jay Walls, and through personal experience, I’ve found these things start best if you prime the living daylights out of them when cold. 8-10 shots with the primer is not too much.

Hope this helps.

best,

PM T2He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

March 31, 2017 at 2:32 pm #55257Thanks, Chris

April 1, 2017 at 1:31 am #55279Have you run your Speeditwin yet? Don’t be intimidated by it. When everything is set right they start easy and run like a top. Very well built. I have a 1949 6039 that I run every summer. It’s one of my favorite motors.

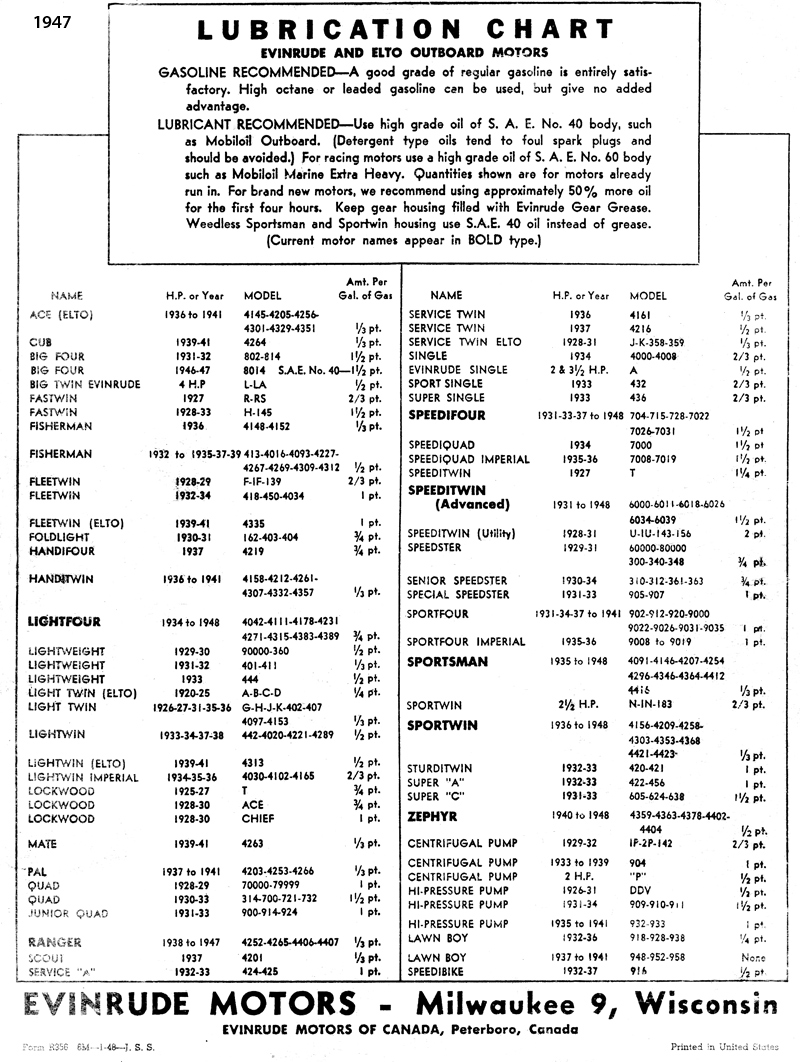

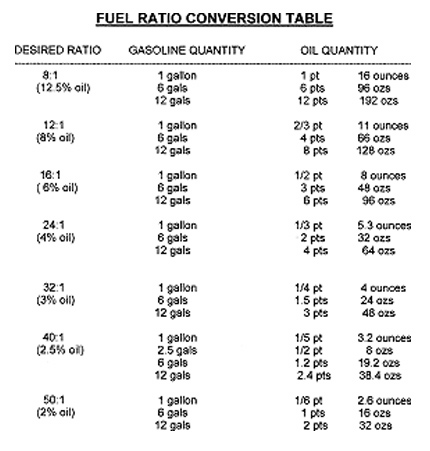

April 1, 2017 at 5:22 am #55286April 4, 2017 at 7:25 pm #55550How many quarts of oil per gallon of gas is recommended?

April 4, 2017 at 9:08 pm #55556In 1947 a pint and a half per gallon was recommended. I have been experimenting with a half a pint of Synthetic TCW3 and half a pint of Low ash aviation 40 weight oil. Lately Steve Woods has been mixing the fuel and I am not sure what it is , but Steve uses it in his Big Four. Dad used a gallon of SAE 60 weight to four gallons of unleaded high test gasoline in his Big Four, but it was extensively re-engineered and ran his 13 foot Lyman to a 54 MPH two way average through a measured mile. . . 😉

-

AuthorPosts

- You must be logged in to reply to this topic.