Home › Forum › Ask A Member › flooding 6hp

- This topic has 17 replies, 7 voices, and was last updated 10 years, 3 months ago by

fleetwin.

-

AuthorPosts

-

April 6, 2015 at 6:10 pm #1119

Hi Guys,

I have a 6hp evinrude, 1965. The motor is flooding; I checked the float needle and float level and both are correct. I can get the motor running but it is blubbering at all ranges and smoking like hell. One thing I noticed is that when turning over the flywheel slowly, there is a ‘gurgling’ noise that I have not heard before. It still makes the usual ‘whoooo’ like an owl. It definitely sounds like fluid is swashing around.

Any ideas before I pull the manifold?

I’m a little stumped why the carb is flooding – the float needle isn’t shutting off the fuel once the bowl is full. The float is a new neoprene type. Needle appears OK, no wear, and it also has the little clip to hold it on the float to open.

Thanks

April 6, 2015 at 6:54 pm #13417Dirt on the needle or missing the washer under the seat.

April 6, 2015 at 7:09 pm #13419Take the float bowl cover off, you will see a post going through the center of float there is a washer on the end. If this dries out or is missing it will run very rich. I make new washers from cork gasket material. You need to feel it compress as you replace the bowl cover.

April 6, 2015 at 7:11 pm #13420I used to run into that when the float was installed up side down …

. . . . . ❓

April 6, 2015 at 7:34 pm #13421

April 6, 2015 at 7:34 pm #13421Fuel pump diaphragm leaking fuel into one crankcase?

April 6, 2015 at 9:24 pm #13427quote mercuryman:Take the float bowl cover off, you will see a post going through the center of float there is a washer on the end. If this dries out or is missing it will run very rich. I make new washers from cork gasket material. You need to feel it compress as you replace the bowl cover.I assume you are speaking about the "boss gasket"?

How do any of you feel about using an o-ring for this?

And; if so….do any of you know the correct nomenclature for the o-ring?

It would seem to me that in lieu of the proper cork gasket…an o-ring would be ok.

If I new the ID for the proper size…I would pick up a dozen or so just to be prepared LOL

April 6, 2015 at 9:32 pm #13428Well, the new OEM nozzle/boss gaskets are some sort of rubber material, not cork, so disintegrating cork should no longer be an issue. I’m sure there is some sort of oring that might do the job, but will it stand up to the stuff in the fuel? I would just stick with the OEM nozzle/boss gasket.

April 6, 2015 at 9:59 pm #13429The O RING number is something like #201 buna n nitrile.

Chris P. probably has the correct # cause he generously sent me a bunch some while back, and they work just fine. Thanks HighTrim !

April 7, 2015 at 2:46 am #13457I’ll check into all the recommendations in the AM as it is the current motor ‘on the line.’ Today was a long work day at my ‘other’ job, but look forward to putting this one to rest tomorrow. This was one of the motors where I picked it up for $50, and the previous owner, who was an auto mechanic, decided to try his hand at an old outboard but only wound up dumping cash into new parts that he didn’t know how to install. He gave up, and I am tasked with undo-ing his work and getting the motor back to where it belongs. The nice thing, however, is that the cowel received a full makeover because apparently he also did body work, and did a pretty nice restoration of the cowel with a really nice clear coat. I’ll post a picture after the jobs done.

It’s always nice when you pick up motor that somebody installed all new parts, but didn’t understand how to install them right and made more work for the next guy. The ignition system is 100% new from his investment (less 1 coil which was shorted, THANK YOU MERCTRONIC MODEL 98), spark jumps a solid 3/8th to 1/2 inch, almost 5/8th inch (which is great for an ‘ol magneto), the driveshaft housing had no roll pin for the lower crank oil seal, the impeller housing had an o-ring on top of the driveshaft gearcase oil seal (there’s a first for me, apparently someone didn’t realize the shift shaft was the issue), and in all likelihood, the carb probably is missing a seal or two. The float he installed wasn’t even close to the right setting.

I had repaired the ignition and fixed an air leak in the gearcase, and on initial run of the motor, found that it was GUSHING gas out of the flooded carb, which is when I pulled it apart to find the float set completely wrong. I’ll double-check my work to see if I missed that venturi orifice gasket and for the seal under the float brass orifice. If those don’t fix things, I’ll double check everything else again and check the fuel pump diaphragm. I don’t think it’s that though because the fuel is pouring out of the carb throat, although you can never rule out multiple problems at the same time. I think if it wasn’t for the ignition being tops, the thing might not even run at all because it would be so flooded. I pulled the plugs and they were shiny metal and dumped gas right out of them. Let’s just say it’s not necessary to pull the choke to get it to fire off 🙂

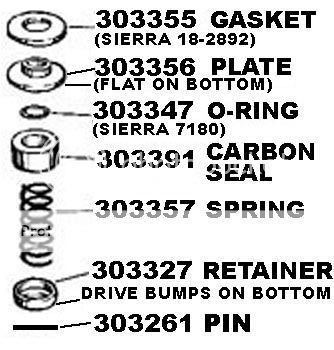

I did have an odd situation which I was hoping someone could shed some light on. When I was reinstalling the gearcase I broke/bent/ruined 2 separate roll pins trying to get everything lined up. It was as if the roll pin was going past the lower seal brass cup and getting hung up in the spring. This isn’t my first rodeo with these 6hp motors, but for the life of me, I couldn’t figure out why it wasn’t cooperating trying to reinstall the gearcase.

I wound up pulling the powerhead, installing the gearcase, then putting the powerhead on the driveshaft. I yanked the powerhead because I wanted to be sure that the brass lower seal cup hadn’t been ‘honed’ out or simple worn out to a larger inside diameter somehow which was allowing the roll pin to go past it instead of compressing everything up against the lower crank. It appeared to be OK at closer inspection. Everything went back together correctly then. The roll pin seemed to be getting stuck on something as I was installing from the bottom up initially; and I did try rotating the prop to get it to slip past the little ‘sneak slots’ at the bottom of the powerhead. What was I missing?

April 7, 2015 at 4:13 am #13461The next time you have a six horse powerhead off, take a moment and study the exhaust housing casting or shine a flash light up it to see that there’s a slot cast in it to allow the pin to pass thru. The driveshaft has to be clocked with the pin facing sideways to clear the casting. Forcing the gearcase off or on is not the way to do it as it will slide right in when the pin is properly aligned.

I hope you are using the proper stainless OMC/BRP 303261 pin to and not a roll pin from the hardware store as the cheap pin will rot out shortly causing the lower crank seal to fail. With no lower seal, these motors tend to let water enter the lower cylinder and we all know what happens next. 😥

-

AuthorPosts

- You must be logged in to reply to this topic.