Home › Forum › Ask A Member › Flywheel "Puller" plater discovery

- This topic has 17 replies, 12 voices, and was last updated 10 years, 8 months ago by

cajuncook1.

-

AuthorPosts

-

April 25, 2015 at 9:44 pm #1327

I have a Johnson TN-26 and was reading the owners manual and found instructions for removing the flywheel. The flywheel has a PULLER plate AKA the rope sheave. The flywheel nut has a wide shoulder and when loosen the nut it lifts the flywheel off. I tried it and it came off easy. I noticed my old opposed twin Evinrudes have the same arrangement.

April 26, 2015 at 12:08 am #14766I still don’t get it…

April 26, 2015 at 12:13 am #14767The shoulder on the wheel nut is beneath the top of the wheel, so that as you loosen

the nut the shoulder strikes the underside of the wheel and lifts it off. It’s a Johnson

thing, I guess. Nice feature.JW in Dixie

April 26, 2015 at 1:31 am #14769And LADAs as well LOL. why would anyone make a machine that does not have it’s own tools incorporated ?

April 26, 2015 at 1:46 pm #14785Interesting that the service manual makes no mention of this ‘feature’.. which is also present on the TD20 and probably all other models which use the same flywheel / recoil hardware.

I’m not so sure about the utility, though, at least not at this late date. If the flywheel was recently removed, this could possibly come in handy.. but if it’s stuck on there, you’re using a puller yoke made of seventy year-old thin cast aluminum with a set of brass drawbolts.

Not really the stuff of flywheel pullers, there. And of course, parts are no longer readily available, if & when you ruin them. 😉

And you still have to remove the gas tank, as there’s no easy way to hold the flywheel to operate the "puller" or torque the flywheel nut. I suppose you could use a piston stop, but.. I’m not sure how those dainty little connecting rods would feel about it. I can say from experience they’re made of some pretty soft stuff.

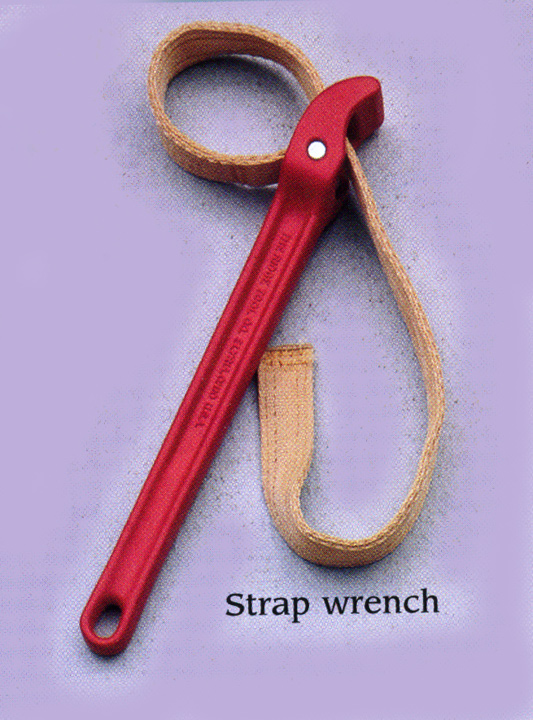

April 26, 2015 at 3:56 pm #14792quote legendre:And you still have to remove the gas tank, as there’s no easy way to hold the flywheel to operate the “puller” or torque the flywheel nut. I suppose you could use a piston stop, but.. I’m not sure how those dainty little connecting rods would feel about it. I can say from experience they’re made of some pretty soft stuff.A strap wrench is the easiest and proper way to hold a flywheel while torquing or removing a flywheel and one of these should be in every outboard motor enthusiasts tool box. 😀

April 26, 2015 at 5:32 pm #14796quote Mumbles:quote legendre:And you still have to remove the gas tank, as there’s no easy way to hold the flywheel to operate the “puller” or torque the flywheel nut. I suppose you could use a piston stop, but.. I’m not sure how those dainty little connecting rods would feel about it. I can say from experience they’re made of some pretty soft stuff.A strap wrench is the easiest and proper way to hold a flywheel while torquing or removing a flywheel and one of these should be in every outboard motor enthusiasts tool box. 😀

Absolutely.. but that misses my point.. because you can’t place the strap wrench without first removing the gas tank.

If you use a conventional puller, you can remove the flywheel by following these steps:

1) Remove recoil housing – (3) screws.

2) Remove fine-wire spring-retainers (3) from recoil ratchet pawls on pulley, and lift off equalizer disc.

3) Remove screws securing pulley to top of flywheel. Unscrew each a bit at a time, evenly, until you can lift off the whole pulley / ratchet assy.

4) Remove flywheel nut with air impact tool, 3/4" socket.

5) Install flywheel puller and pull flywheel. If you need to hold it steady to torque the pressure screw, you can slide a bar between the puller drawbolts.No need to remove the gas tank. Re-install is reverse of procedure, again using air impact to torque flywheel nut. But if you’re using the ‘built-in’ puller, there is no easy or safe way to slip a bar in place during step #5.. So you end up removing the gas tank to get a strap wrench in place, or using a piston stop (not really recommended).

But hey, we all have our methods, right?

April 26, 2015 at 7:17 pm #14801Yeah, I use an impact to but I don’t like recommending it on this forum as it takes an acquired feel to use one properly. To avoid risking any damage it’s still best to use a strap wrench.

April 26, 2015 at 9:47 pm #14811There is a reason that using the rope sheave for a flywheel puller is no longer listed in the service manual. It is because it only works under ideal circumstances. Many outboards are used in less than perfect conditions, and can be "Serviced" by individuals who don’t know what end to stick in the water. Failure to properly torque the flywheel nut can lead to disaster. Too lose can lead to a sheared key and scored crankshaft. Too tight can virtually weld the flywheel in place. Longtime storage in a damp, salty atmosphere can do the same. Aluminum does not have the strength to pull the flywheel under these circumstances. That is the reason OMC designed there flywheel puller, and why they encourage it’s use.

. . . . . . 😉

April 26, 2015 at 9:58 pm #14813

April 26, 2015 at 9:58 pm #14813Here is a simple cheap tool you can make for holding the flywheel. The metal plates cost $2.50 at home depot and the holes are predrilled.

Two of the three flywheel rope plate screws go in the end of the tool. THe handle can be made of any appropriate stock you have on hand. -

AuthorPosts

- You must be logged in to reply to this topic.