Home › Forum › Ask A Member › flywheel tool?

- This topic has 17 replies, 12 voices, and was last updated 7 years, 10 months ago by

kees.

-

AuthorPosts

-

May 31, 2017 at 3:27 pm #7182

hello, i have several 50’s and 60’s johnson and evinrudes from 3 to 40 hp.i have learned the hard way that the flywheel needs to be torqued.is there a tool to hold the the flywheel while torquing.if not i weld and can make one.any ideas appreciated.thank you

mn

May 31, 2017 at 3:31 pm #58688Strap wrenches from Harbor Freight. Or nail a loop of military or similar web belt onto a length of 2" x 2" wood. Only thing Uncle Sam gave me that was useful after the Korean War.

May 31, 2017 at 3:34 pm #58689do the strap wrenches really hold.i know my 40hp torque is pretty high.100 ft lbs or so

mn

May 31, 2017 at 3:45 pm #58690May 31, 2017 at 4:41 pm #58694Serpentine belt is even better than military belt. Didn’t have those when I made my strap wrench.

Torque? Depends on how long the handle is and who you have to help you.

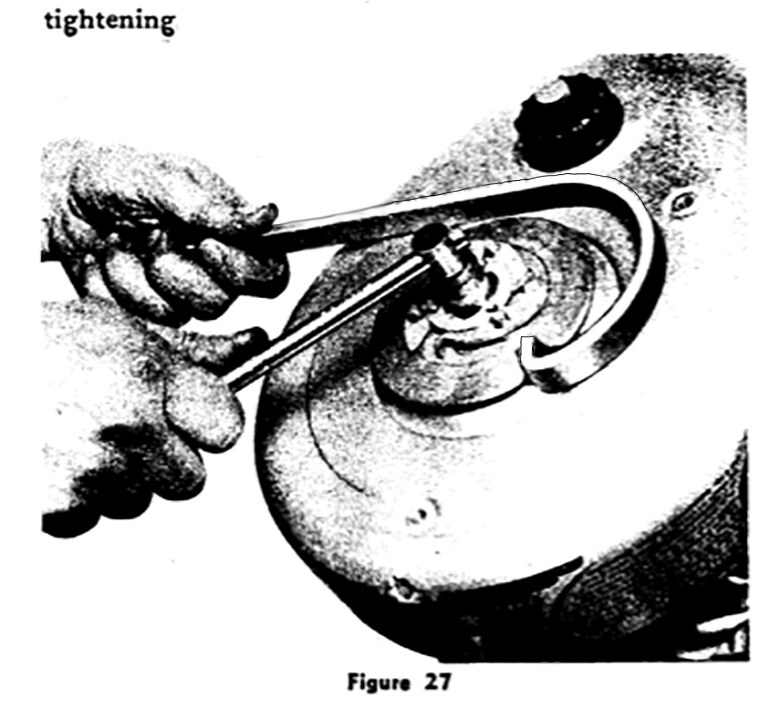

June 1, 2017 at 12:00 am #58718Back in the dim past when most outboards had two notches in the rope sheave for starting, I used this copy of an early Evinrude flywheel holder.

Another special tool from the mid 1930s was the Spanner hook.

However when they came out with the 40 horse using over 100 foot pounds of torque this would not do. I tried a holder that used the ring gear teeth.

It bent and slipped. so I got a chain pipe wrench with an extra chain to fit the largest flywheel. For tough jobs I slip a pipe over the handle. It has worked for over 50 years. . . 😉

June 1, 2017 at 12:19 am #58725

June 1, 2017 at 12:19 am #58725I don’t know if this will get me shot or flammed but I keep a rope like 3/8 inch in diameter and with 1 piston on engine in the down stroke insert it into the cylinder and cram as much into the cylinder as I can. Then turn the flywheel to loosen or tighten depending on what I am doing. Has worked well for me a lot of times on a lot of engines. Might not be preferred method but works in a pinch when missing some one to help hold flywheel.

Joe

June 1, 2017 at 12:28 am #58726I won’t flame or shoot you Joe. It just seems like the puts way too much stress on the engine internals. Much better to get a hold of the flywheel and not transfer all that force through the crankshaft, rod, piston, and head.

-BenOldJohnnyRude on YouTube

June 1, 2017 at 12:31 am #58727I know but how much force is actually applied to a running outboard engine??? 80lbs?? on a flywheel nut close to max lbs for that nut?? I would think more force is put on internals than that when engine is working.

I do admit this isn’t’ the right solution but can be used in a pinch.

Joe

June 1, 2017 at 12:51 am #58732Shoving a rope in the spark plug hole is actually in a few of the manuals. I suppose if it was good enough for the Engineers, should be fine. I prefer a flywheel holder myself, but don’t think it would do any harm.

-

AuthorPosts

- You must be logged in to reply to this topic.