Home › Forum › Ask A Member › Gas / fuel leak help on a 1954 25hp Johnson RD-15

- This topic has 39 replies, 11 voices, and was last updated 3 years, 5 months ago by

crosbyman.

-

AuthorPosts

-

October 31, 2021 at 7:26 pm #248990

I just recently bought a 1954 Johnson RD-15 25hp, which I now have in running condition. My sons and I (ages 10 and 11) replaced the obvious worn parts of the motor including a complete carburetor kit, the low speed carburetor needle, the entire ignition system, the upper crankshaft seal, gas tank o-rings, impeller, impeller plate, and impeller housing, and the pull rope. The motor now starts on the first pull and I am very impressed with it. It is insanely loud, 103dB at WOT, but there are earplugs for that. Overall, I very much enjoy this outboard, the simplicity of it, and working on it.

After our first trip to the lake, we noticed a significant amount of gas / oil mixture running down the mid-section of the outboard. What you see pictured below, is after I wiped up the mess. After some initial google searches, I figured it was probably something related to the bottom crankshaft seal, or bottom powerhead gasket. I purchased both, and we tore into things to figure out what was going on.

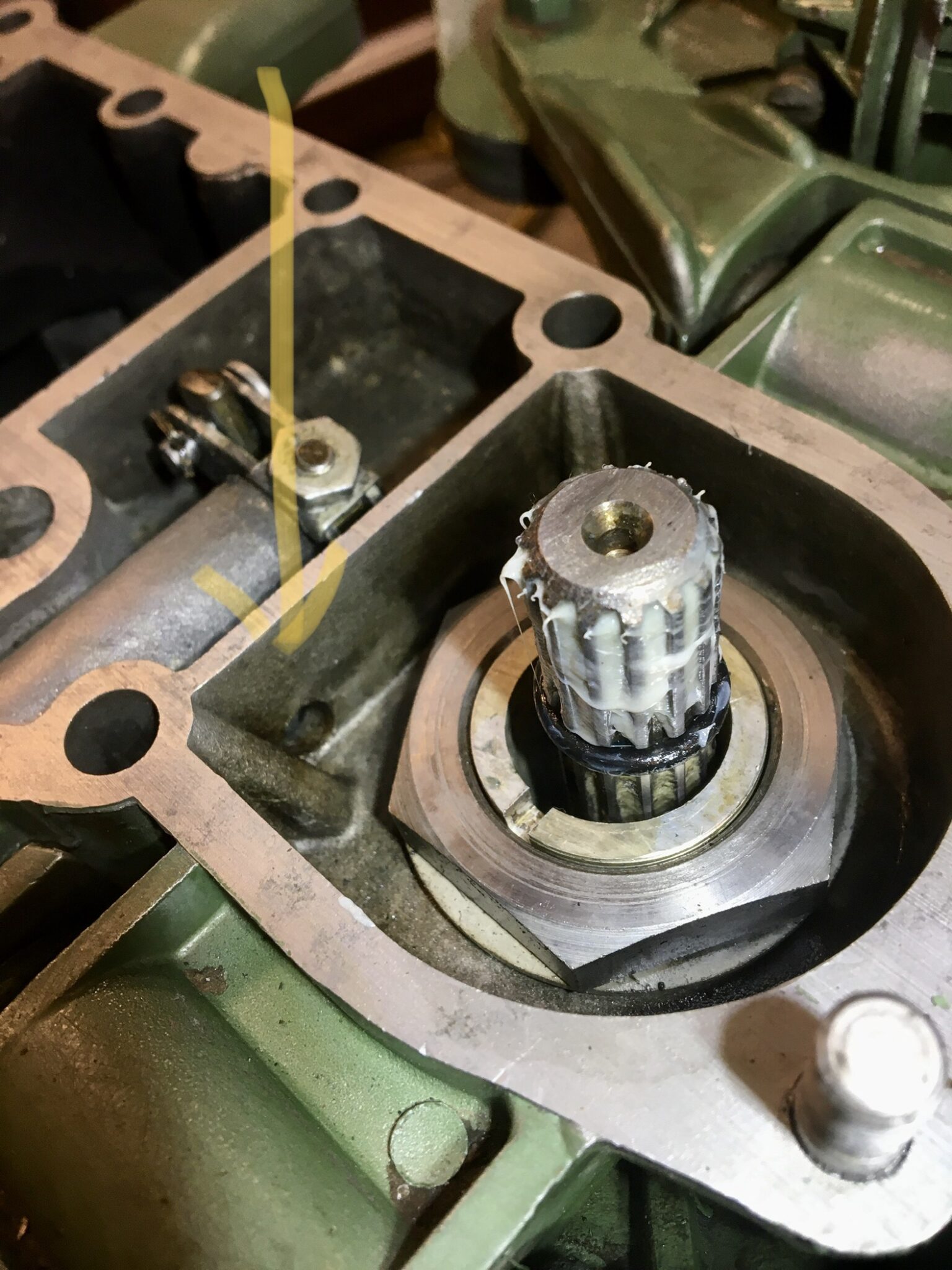

After hours of head-scratching, manual-reading, and Internet searching I figured out that the gas I found surrounding the giant nut around the driveshaft was coming from excess gas in liquid form in the engine. There is a check valve that allows this excess liquid to escape from the engine, into this chamber, and then out the hole in the back, into the exhaust.

So the gas comes through the check valve out of this hole next to the carbon oil seal

and goes into the exhaust through this hole as pictured below.

This process is described in the 10th edition manual on page 256.

So my question is, why is this gas-oil mix running down the outside of the midsection? I would think the oil / gas would all go down the exit hole, rather than finding other places to go. Is this something I just need to live with, or is there another seal or gasket that I need to replace?

I already replaced the lower carbon crankshaft seal and o-ring while I had this open, and have a new base gasket 302625 to install, but is there something else that I’m missing?

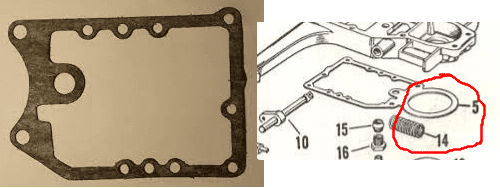

I also bought a new gasket 302821 just in case, but I am doubting that it would help, since that gasket has been changed to not include any gasket material in the area where the gas / oil mixture is running down the mid-section. I believe that the newer gasket without the giant circle (highlighted in red) in the front is already the gasket that I have currently installed.

I’d rather not install gasket 302821 unless absolutely necessary, since it appears that the procedure is a bit involved, and involves tools I don’t own.

Thanks in advance for your help!

October 31, 2021 at 9:18 pm #248999Some of the unburnt gas / oil mixture is probably taking the path of least resistance.

I can’t remember if that swivel tube joint has a grease zerk, but if so, if might slow

down the mess, but I doubt it.Those engines are somewhat inefficient in burning fuel.

Some are using a more environmentally friendly two cycle oil, Amsoil, Penzoil synthetics, etc,

that burn cleaner, and make less of a mess.That said, idling these motors in a barrel are going to make more of a mess than

running at speed on a boat, and fine tuning the carb.Perhaps others will have more useful ideas.

Prepare to be boarded!

October 31, 2021 at 9:38 pm #249001Jdean, I guess you’ve already figured out that that is crankcase puddle drainage, which is normal. As for coming out around the steering swivel pin, I don’t remember if that pin is sealed or not—but I highly doubt it. Hey, it’ll keep the steering well lubricated.

October 31, 2021 at 9:48 pm #249002and on pages 191 192

Joining AOMCI has priviledges 🙂

-

This reply was modified 3 years, 5 months ago by

Mumbles.

Mumbles.

October 31, 2021 at 10:48 pm #249004Thank you everyone for your responses!

I will definitely look into a more environmentally friendly 2-cycle oil. I was a bit entertained in the manual on page 256 where it said, “Do not be alarmed if an oil “slick” forms on the surface of the water when operating for any length of time at slow speed–it’s the result of crankcase bleeding as described.” Yeah… i left the boat idling at the dock to warm up with my boys while I parked the truck and boat trailer, and I came back to a definite “oil slick” at the dock. I don’t care what the manual says, it IS alarming because I’d prefer to leave things better than I found them if I can, not covered in oil.

Initially I was very concerned that the inner crank seal had blown and all of the gas / oil was leaking out. I am very relieved to find that this is just a normal function of the engine to flush out the extra gas that accumulates. I hope that sometime in the last 70 years, someone has figured out how to use this fuel and not just dump it out the exhaust. I would assume that modern 2-cycles have this feature? 🙂

Yes, my steering will be incredibly well lubed!

I have been searching around to see what I should be torquing down the bolts to that hold the powerhead on. Since I can’t find anything, I’m assuming that how tight they are isn’t that important, just coat the base gasket in gasket sealing compound and snug them down?

Thanks again for being willing to share your experience and wisdom!

October 31, 2021 at 10:56 pm #249006Modern day outboards are way more efficient than those like yours from the 1950s. With modern technology and full synthetic oil, my current Evinrude ETEC puts out zero smoke and zero fuel/oil slick. As others have noted, you will do better with a synthetic blend or full synthetic oil and once you have the carburetor dialed in, it will be somewhat better but you can never totally eliminate the unburned fuel/oil mix that are just naturally inherent with the old design.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."November 1, 2021 at 9:29 am #249010actually… if you really want to sleep better …there is a utube video.. or article somewhere where the guy modifies the purge valve and routes the ejected residue into a small container inside the boat.

Hey ! who knows maybe the 2 line tanks could become useful again by routing the oily residues back into the tank itself if the engine was modified for a pump operation.

.

one line would suck gas from the tank (tank cap open of course) …. and the second parallel line no longer needed could be used to return the oily crankcase residue back to the tank to be recycled. 🙂the only oil into the lake would be limited to “some” unburnt fresh fuel/oil mix pushed out the exhaust ports during the upstroke.

Joining AOMCI has priviledges 🙂

November 1, 2021 at 11:40 am #249014Crosbyman, now we are getting somehwere! After a bit of googling, I found this post:

https://www.aomci.org/forums/topic/unburned-fuel-collection/

I will need to do some more research before I feel confident in drilling holes and making the modifications, but this looks 100% worth it. Based on my limited use of this motor, these bigtwins seem to use a huge amount of fuel, and I would be glad to save as much as possible, and not just dump it in the beautiful lakes round me.

I also am very interested in the idea of converting to a fuel pump, and then converting the second line from the tank into an unburned fuel return line. I think I will start with collecting the unburned fuel in a bottle and go from there.

THANK YOU!!

Once again, you guys far exceed my expectations!

November 1, 2021 at 12:28 pm #249017Check this out.

https://www.aomci.org/forums/topic/unburned-fuel-collection/

November 1, 2021 at 5:04 pm #249023hey….! Chris P stole my idea back in 2017…. 🙂 🙂 🙂

I installed a fuel pump on a couple different motors, but kept the 2 line system. The old AIR line I transformed into the new FUEL RETURN line from the barb. I then drilled/tapped a vent system onto the pressure tank. From initial glance, appears completely bone stock. Unless you look closely!

Joining AOMCI has priviledges 🙂

-

This reply was modified 3 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.