Home › Forum › Ask A Member › Gear Case Sealant

- This topic has 16 replies, 10 voices, and was last updated 9 years, 2 months ago by

johnyrude200.

-

AuthorPosts

-

February 10, 2016 at 9:50 pm #3614

I remember this being discussed recently but now I can’t seem to find it.

I have refurbished the Johnson clam shell gear case and now have one to do

on my 50hp Chrysler Force.

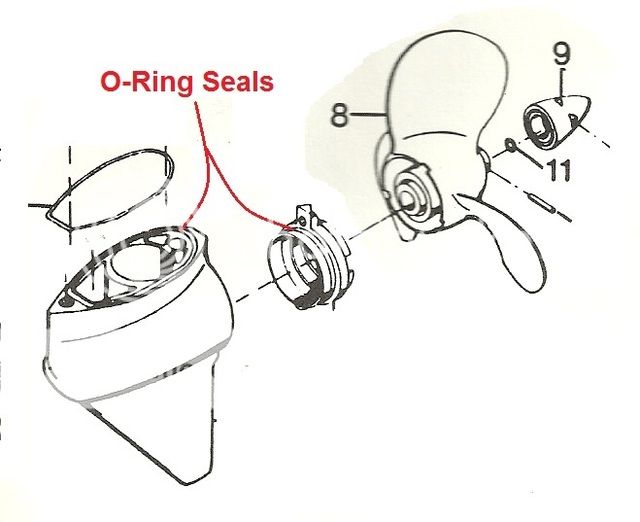

Got it all apart without any issues – bearings are okay. The pinion gear has a

broken tooth so I opened the old 35hp Force to see if they match, and they do.

and I noticed that both motors do NOT have any sealant on the o-ring seals – at all.

and BOTH leak water into the case, but can’t tell where the water is actually coming from.

I put in a new water pump, lower shaft seal and shift rod seal a few months ago.

so, I have a new total seal kit on the way for the 50 and all parts are clean and mating

surfaces are good to go……. I know it won’t hurt anything if I put sealant on the

seals – or – will it ? The bearing cage is a friction fit held in with two bolts top and bottom.

Additional insurance to use the sealant ?

February 10, 2016 at 9:53 pm #31748

February 10, 2016 at 9:53 pm #31748I put 3M 847 on all my gearcase o rings and spaghetti seals.

February 10, 2016 at 11:18 pm #31752Gasket sealing compound is all you need on an O-ring. The compression of the O-ring does the sealing.

In a Johnson/Evinrude gearcase I will dab 847 in the groove to hold the spaghetti seal In place. Once in place then I use the GSC.February 11, 2016 at 12:10 am #31756Pappy and Chris,

When you do your gear cases, do you use OEM spaghetti seals, or aftermarket (Sierra, NY Marine’s, or other). Is any one seal better then another in your experience?February 11, 2016 at 12:28 am #31757I have not ever tried Sierra, so cannot comment on it. I have used OEM, and other aftermarket. Pretty basic stuff though in my opinion. Not sure anyone could mess making that up!

February 11, 2016 at 12:39 am #31758I bought a 10′ piece off of ebay for $5 + free shipping.

10 FEET BUNA O-RING CORD .103" 70 DURO RUBBER 3/32" THICK

I have probably wasted a foot of it trying to develop the technique of getting a square cut end.

February 11, 2016 at 2:27 am #31766Anonymous

Johnny: what’s your technique?

February 11, 2016 at 2:41 am #31767what I found that works best for me is rolling it on the table with an X-Acto blade

or single edge razor blade and just slowly cutting partially through at a time all the way around.

But, I have only been messing with spaghetti seal for a couple of months now. Complete NOVICE.

I think that if I was in the business, I would make a small guillotine to slice it with.

I do understand the concept of having a square tight end against the shaft seal being paramount.February 11, 2016 at 3:39 am #31771If you don’t have any 847, try using some Permatex Ultra Black Gasket Maker. It’s an RTV adhesive sealant and it doesn’t care if the ends of the spaghetti are cut square or not. Once it’s set, it’s leak proof.

February 11, 2016 at 3:08 pm #31786try Dollar store pill cutters

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.