Home › Forum › Ask A Member › Gear Case

- This topic has 19 replies, 9 voices, and was last updated 7 years ago by

johnny-infl.

johnny-infl.

-

AuthorPosts

-

March 25, 2017 at 2:43 am #54845

It’s also a good idea to seat the front (thrust) bearing by tapping on the end of the prop shaft with a soft hammer while tightening the screws and turning it at the same time to make sure it’s free.

March 25, 2017 at 11:58 am #54855FrankR – are you referring to part # 35 Retaining Ring as being tapered ?

are you talking about the thickness of the ring or the fat part at the bottom

and the skinny part at the top where the eyes are ?

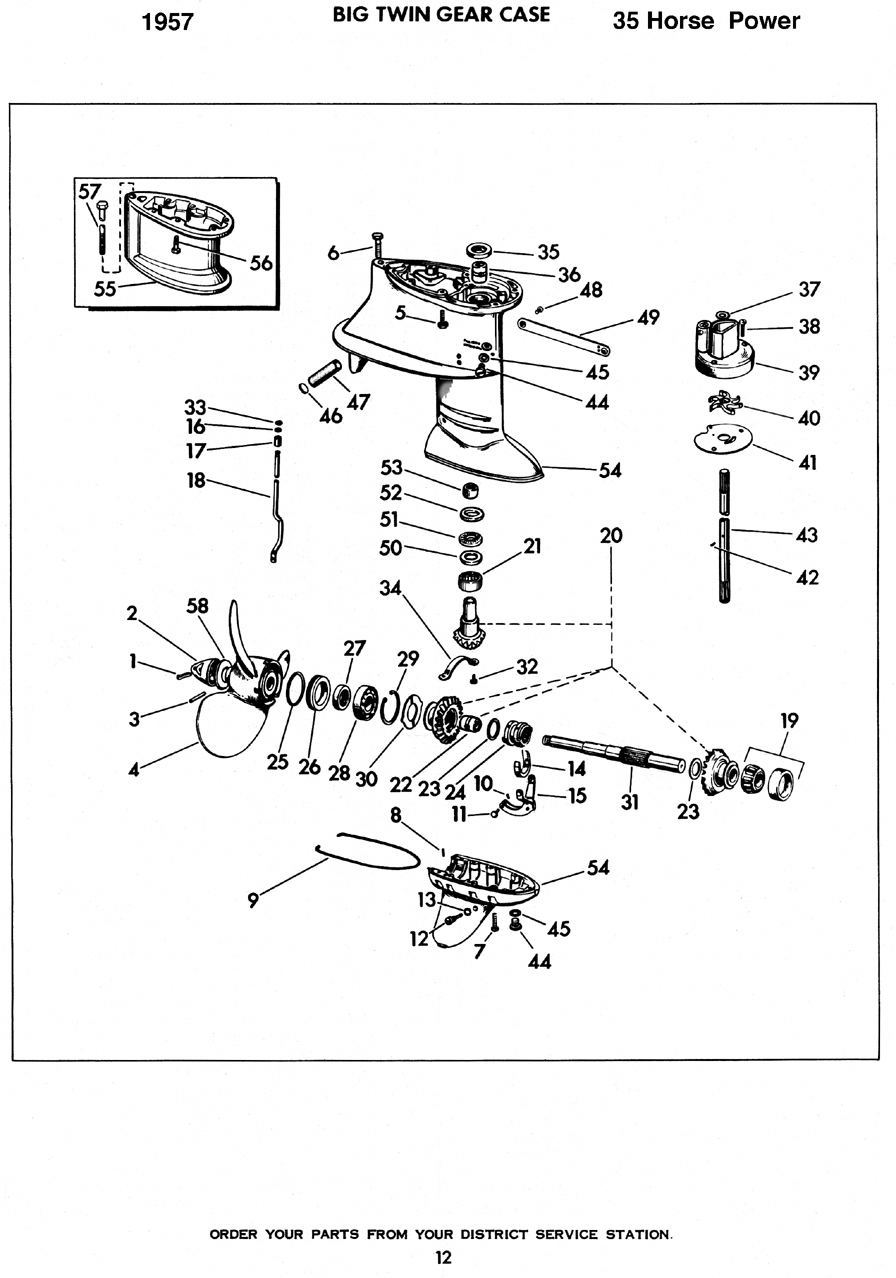

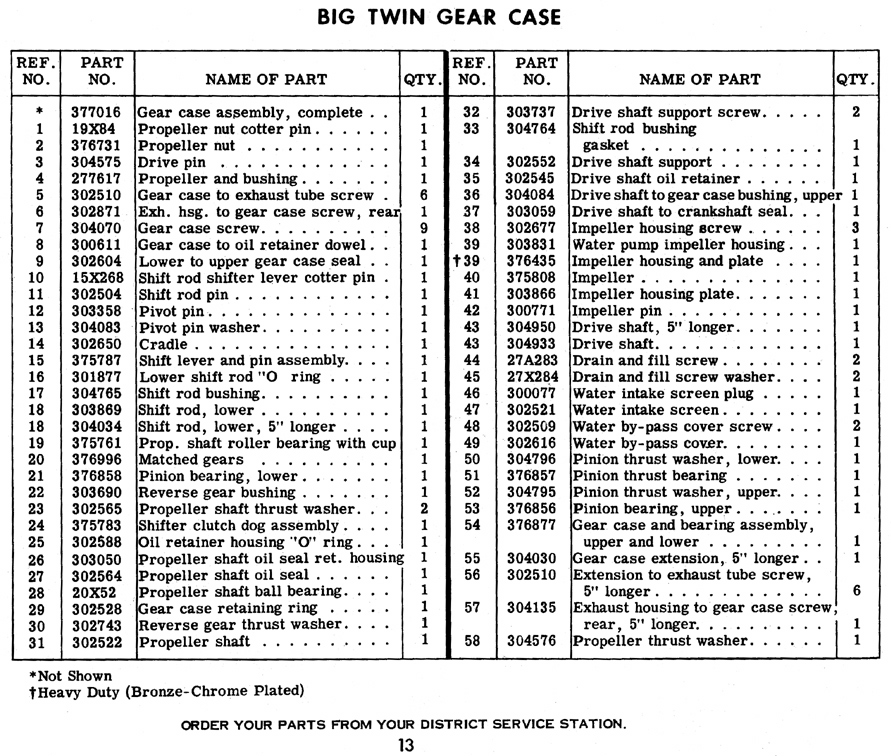

the ring I have is .006" thick all the way around.Item# 17-A alignment pin must seat properly

items circled in red gave me some issues when I was

first learning how to refurbish the RD gear case. (Thanks Pap)

http://www.marineengine.com/parts/johnson-evinrude-parts.php?year=1957&hp=35&model=RD-19&manufacturer=Johnson§ion=Gear+Case+Group

assemble – disassemble / check – double check a few times dry before buttoning it all up for good..

March 26, 2017 at 2:48 am #54908The 1957 35 horse power gearcase must have the 0302528 "gear case retaining ring" facing the right way. One side is flat, the other side is tapered. The flat side must face the rear to take the thrust of the reverse gear. If reversed it may not drop fully into the recess. Further, it may pop out when shifting into reverse, allowing the reverse gear to push back until stopped by the tabs on the 0392743 thrust washer. This will damage the oil seal integrity. This error in the 75 horse V4 results in the loss of prop, prop shaft, prop shaft seal retainer and reverse gear. . . 🙁

March 26, 2017 at 1:20 pm #54923

March 26, 2017 at 1:20 pm #54923wow – Thanks Frank and Garry !!

Edit:

Looking at the parts diagrams of the 1957-RD and the 1958-RD

they both take the same 0302528 Retaining Ring.I just went out into the bright Florida Sunshine where I could see clearly

with my old eyes and – Low and Behold !! there is a slight raised ridge

on one side of the ring and a flat surface on the other side.

I have handled this ring a hundred times and never noticed there

could be a "front and back" side !!!!! Thank You !! for the clarificationTHIS is why Friends should not let Friends – WORK ON MOTORS !!

.

March 26, 2017 at 2:34 pm #54925Great info, I opened up a similar gearcase last night. Now I have to pay more attention when assembling. Thanks

March 26, 2017 at 5:40 pm #54954That’s GREAT info. I have a couple of these to work on sometime soonext and likely would have never noticed this.

-BenOldJohnnyRude on YouTube

March 26, 2017 at 6:49 pm #54959Garry – you said in the 75hp that reversing the retainer ring could cause huge damage . . . . .

how about in the early 1960s 33 and 40hp ????

I am thinking now that I have to take apart the gear cases to check it before

the motors are run…….. 50/50 chance of being installed wrong !!!

I have refurbished a 33 and two 40 hp and now am buttoning up the RD-19 and RDS-20.

Thank You again for sharing your life-long experience !! you are a true icon !!.

March 26, 2017 at 9:15 pm #54968Just finished lower unit, works great.

Johnnys picture helped me out, my shift rod was on the opposite side of prop shaft, along with pin and cotter pin. Had burrs on face of housing on gearcase and bearing, apparently caused with screwdrivers or punch’s trying to get apart, took burrs off with 4" sharpening stone.

A little too much grease, I had put 847 on o-ring, replaced with new o-ring, put oil around ring.

Put together for a dry run, fell right in place.

Put enough 847 to hold spaghetti seal in spots, finished 847 on skeg, fell in place, hand tighten screws, tap bearing assy front and back, used hand impact to finish tighten screws, checked shift and prop shaft, almost looked like I knew what I was doing.

Nice to have help when you need it, Thanks, Gene.

Question: The drive shear pin I took off was steel, I have seen a few with bronze or brass pins. Do the steel and the brass pins go to different horsepower class?March 26, 2017 at 9:19 pm #54969Yes brass pins are shear pins, SS pins are called drive pins, and are for motors with props with rubber hubs like yours. The hub will fail it the prop hits a submerged object. The motors with brass shear pins usually have a solid prop. So they need the soft brass to protect the powerhead from damage should the prop hit a submerged object.

March 26, 2017 at 9:28 pm #54970Gene, on your next re-do, wet sand the mating surfaces of the clam shells

on a solid flat surface – such as the kitchen counter.

wet the back of the 320 grit wet-or-dry paper so it will stick to the counter top

wet the paper and sand in a figure 8 fashion until you see an even shiny surface on both parts. -

AuthorPosts

- You must be logged in to reply to this topic.