Home › Forum › Ask A Member › Goodyear See Bee 025-3564

- This topic has 28 replies, 6 voices, and was last updated 8 years ago by

frankr.

frankr.

-

AuthorPosts

-

March 28, 2017 at 1:51 pm #6635

My Grandfather bought this engine new back in the early 50’s. Now I have possession of it and hope to use it on my private lake. My uncle who had this engine for the last 30 years had someone work on it and told my uncle that it was in excellent condition except that there were two filters that had to be cleaned. He cleaned them and the engine ran great. Two years goes by and the engine is not used at all. This is where I got the engine. So I called a local repair shop and I asked them about mixing the oil. They told me to use a 40:1 mixture. So I put the mixed gas in the engine and put it on the boat. 3 pulls later the engine fired and ran great. I ran it for about 30 minutes and then took the boat in. The very next time I tried to use it, I could not get the engine to fire. So I went to the manual and made sure I had gas, Vent cap was open and primed it for 8 to 10 seconds. Despite my best efforts, no fire. I took it out another day still with no fire. My question involves the meaning and use of the "shut off valve". What is it? I see in the diagram that there is a "Carb Shut off needle" it is on the front of the engine and below the throttle. I could see that it could turn right and left but I have no idea what it is for or how to use it. Also, does anyone know where I could get extra sheer pins for this motor? Does anyone know where I could get a replacement pull start handle? Lastly, I would love to bring this motor to someone and have someone check it out and help me know the critical maintenance and how to properly use it. Also, was the 40:1 mixture level correct? I live in Indianapolis Indiana.

Sorry for all the questions. I am new to this engine and outboards in general. I am an experienced boat owner but not this type of engine.

Any help or suggestions would be very much appreciated! Thanks Rob

March 28, 2017 at 5:59 pm #55111Hello Rob,

Welcome to the site. There is a vast amount of knowledge here and lots of great folks willing to help. Your early 50’s Sea Bee is built by the Gale division of OMC. The correct gas to oil mix ratio for this engine is 16:1, not 40:1. These engines use bronze bushings and not needle rollers so they need more oil. The "Shut off valve" is the valve that turns the flow of fuel mix on and off from the tank. I’m not sure where that valve is located on your particular motor, but you should have three knobs on it. There should be a high speed carb needle adjustment, a low speed carb needle adjustment, and the fuel shut off. The fuel shut off would should be turned to the left until it stops to open the fuel flow to the carburetor. The high and low speed adjustments.should be labeled as such. The fuel shut off probably us not labeled. I do not yet have any Gales this early so I’m not certain where the fuel valve is, but someone will know. They are usually close to where the fuel line connects to the tank.Maybe that will get you started. No problem with questions. That’s how you learn.

-BenOldJohnnyRude on YouTube

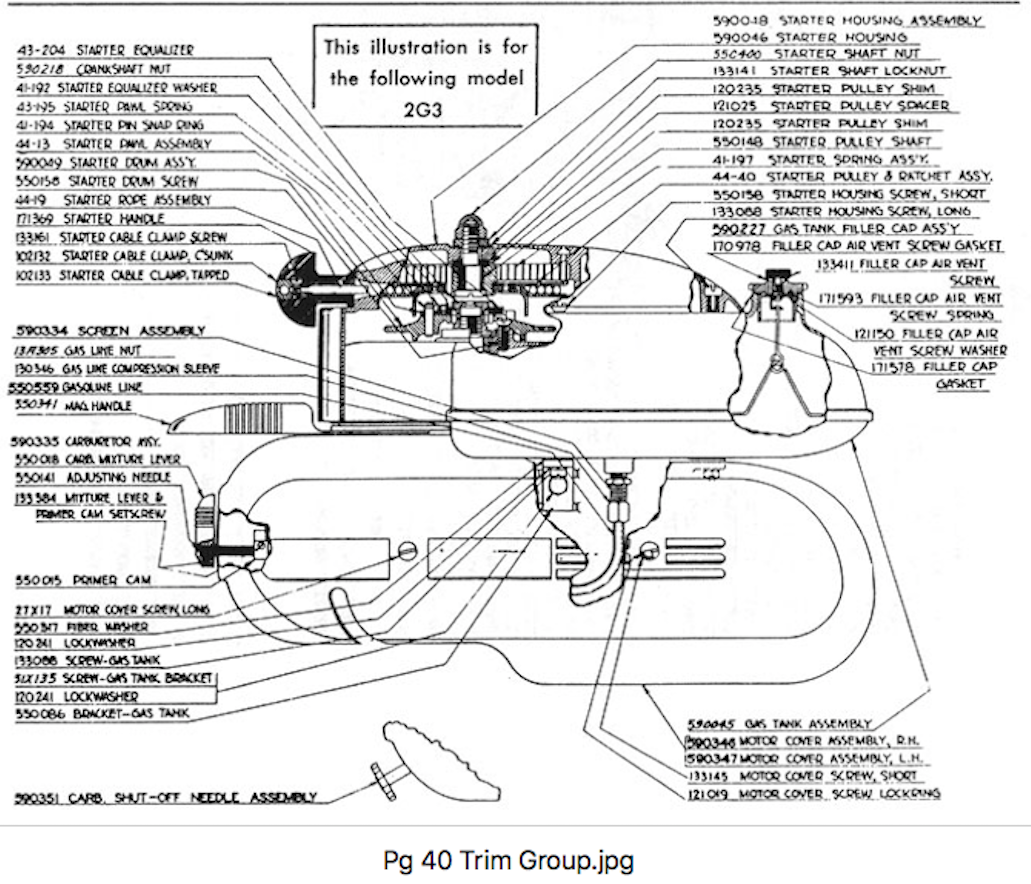

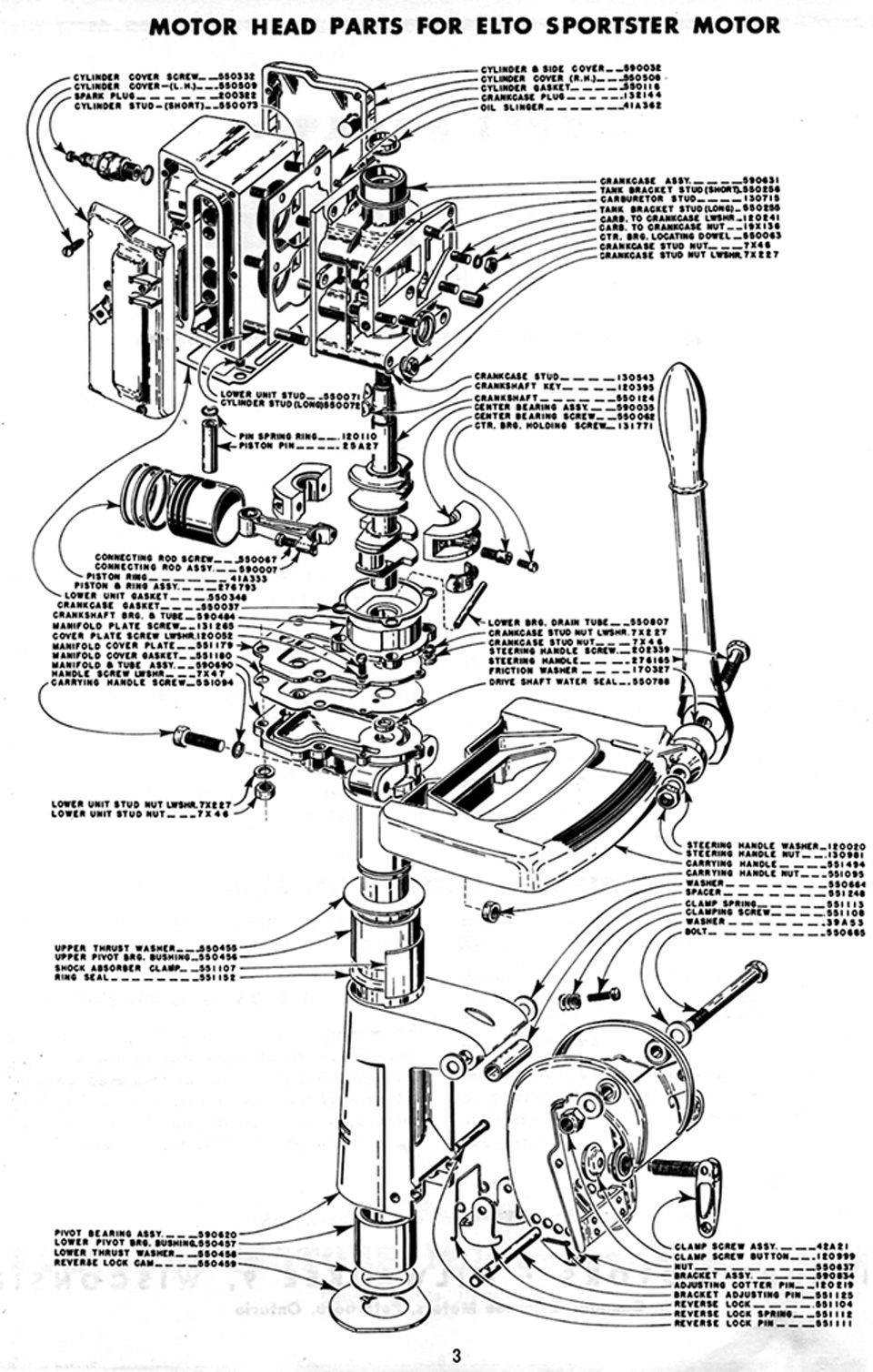

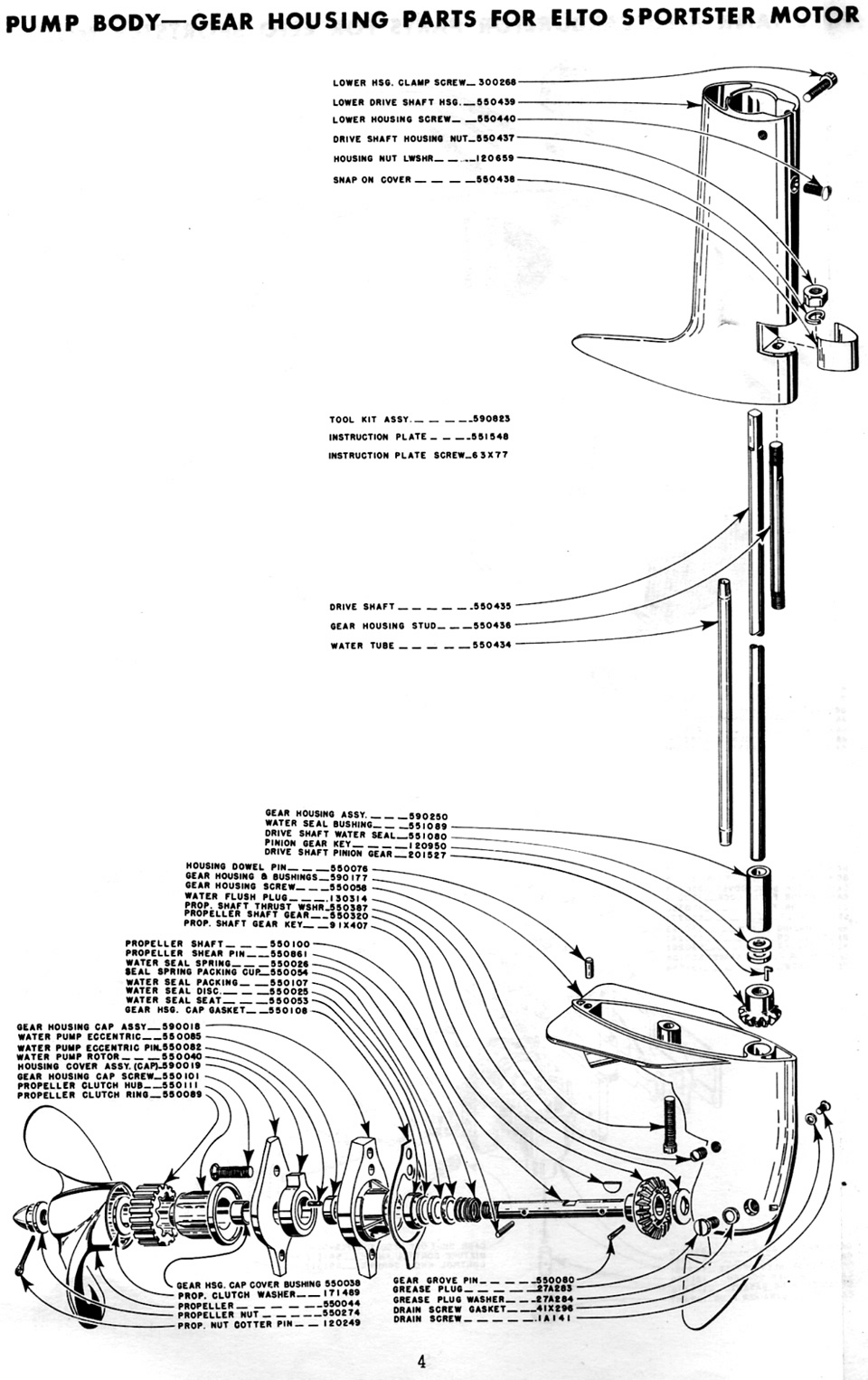

March 28, 2017 at 6:26 pm #55115That would be a 1948 five horse Gale Products model 2G3 – One of Gale products more popular models. With a different trim, color, and gas tank, it was sold by Evinrude under the Elto label.

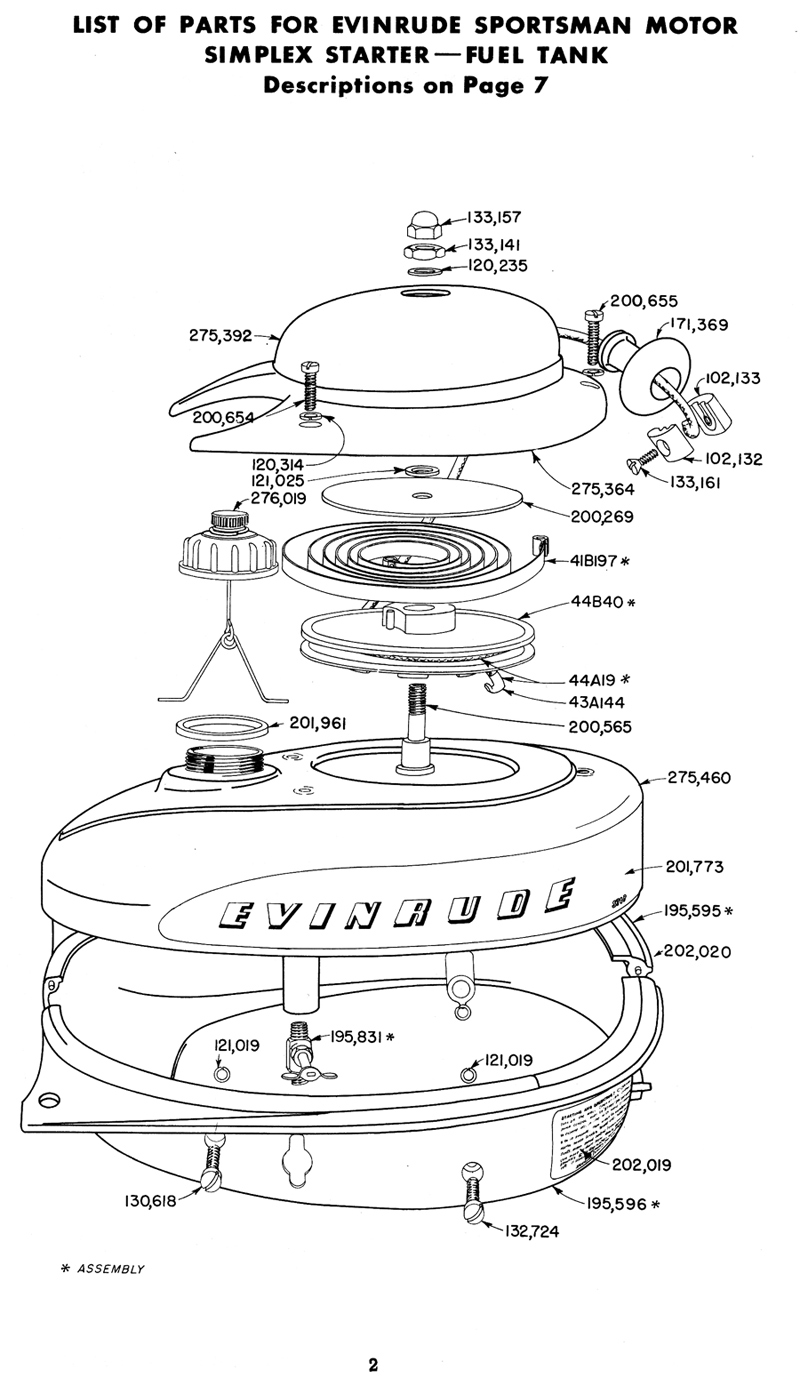

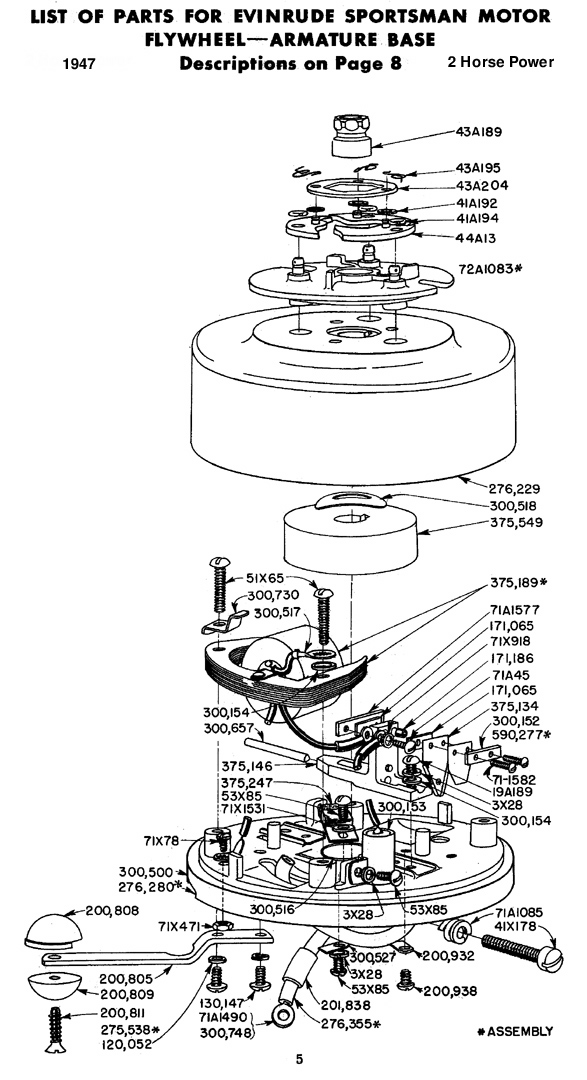

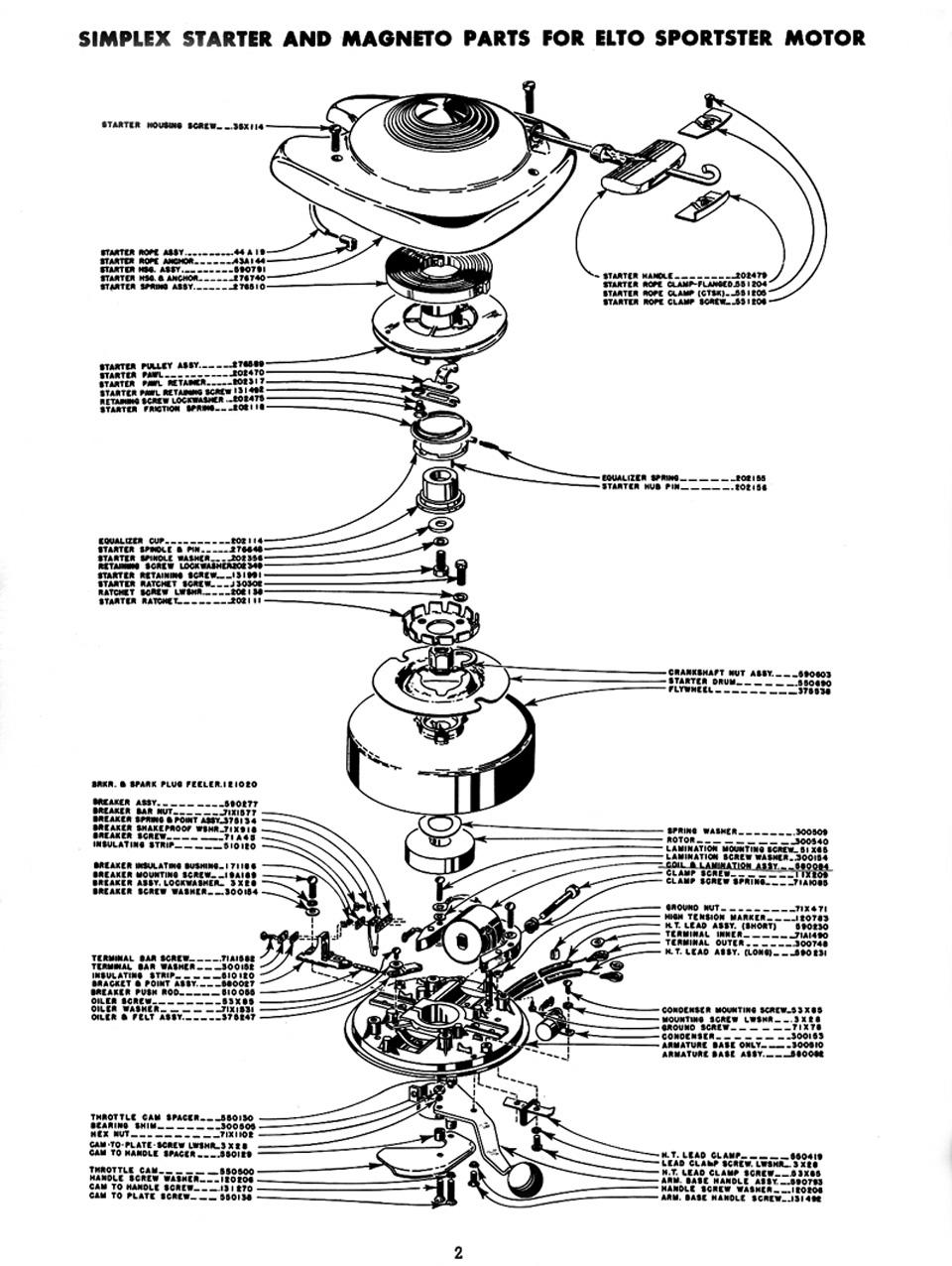

Most parts for the Elto are carried by the parent company of Evinrude, now BRP. This would be the insides of the starter mechanism. (On a different motor.)

This is the 5 horse Elto – A year newer with a newer starter – guts of which were used on 40 horse Evinrudes for 10 years. . . 😀

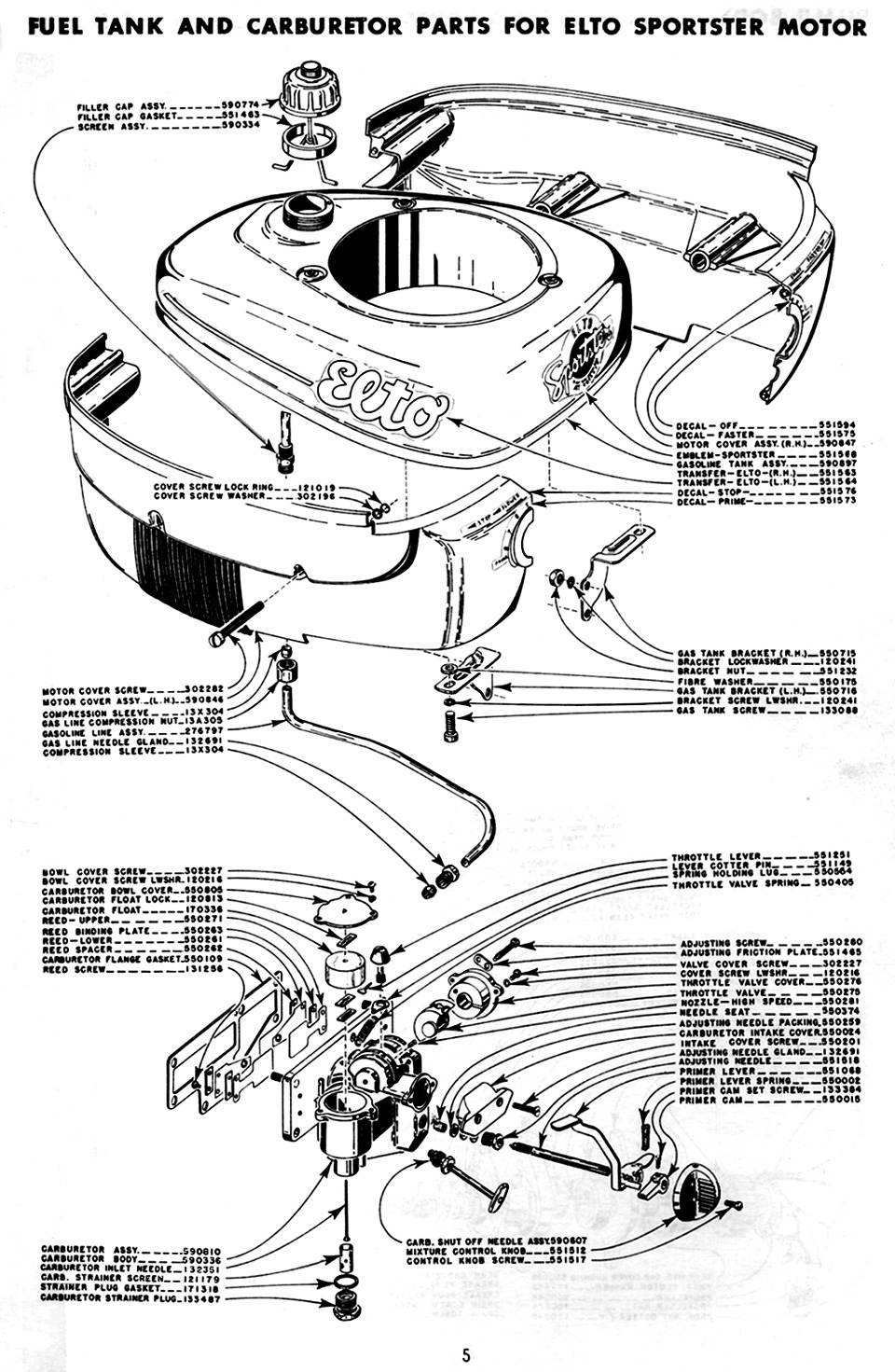

– And the carburetor . . . 😉

The bottom shut off needle is a shut off valve. Turned all the way in, it shuts off the fuel to the carburetor. It is turned all the way out to run the motor. The high speed adjustment is adjusted for best running at high speed. The low speed adjustment is a bit tricky. It adjusts how far the carburetor venturi (AKA throttle valve) stays open at an idle. Turning it out is easy. Turning it in in some cases can damage the ramp it rides against on the venturi. I find it best to speed up the motor slightly , turn in the adjusting screw and then retard the magneto lever to see how the change effects the idle. One strainer screen is at the base of the carburetor bowl. The other is in the fuel tank. The fuel mix was given as a third of a pint to the gallon.

March 28, 2017 at 6:29 pm #55116

March 28, 2017 at 6:29 pm #55116Nothing wrong with Ben’s post except he got the wrong year. You have a 1948. It is a 5hp motor, Gale model 2G7. The big knob is a combo high speed mixture adjustment and primer. The fuel shut-off valve (fuel from the tank) is right below the big knob. The idle mixture adjustment is a small screwdriver slot screw on the side of the carburetor and works by holding the throttle valve partly open at idle speeds.

Yes, 16:1 is the correct mix.

March 28, 2017 at 6:41 pm #55118Thanks for all the information. Specifically, The fuel shut off valve below the big knob (Carb shutoff needle) , can turn to the right and turn to the left. Which way should it be turned for starting the engine? I think this may be the root cause of my problem.

March 28, 2017 at 7:08 pm #55119I believe it is a right hand thread with a valve seat in the bottom. CW to close, CCW to open.

-BenOldJohnnyRude on YouTube

March 28, 2017 at 7:33 pm #55121Open it all the way to run the motor. Close it all the way before laying the motor down so it doesn’t leak gas.

March 28, 2017 at 7:37 pm #55122Ok, I will go play with it now using the right oil and having the carb shut off valve full open full CCW

Thanks everyone for the advice and information!!

RobMarch 28, 2017 at 7:42 pm #55123About the big knob–To start a cold motor, turn it all the way to the left which holds the float pin down, flooding the carburetor. That provides an extra gulp of fuel (instead of a choke). The book will tell you a number of seconds to hold it. I just hold it till it drips gas, then turn the knob to the right to release the float pin. It should start right up. Once running (on a boat on the lake), move throttle to wide open position and adjust the big knob to where it runs the best. At this setting, the knob should be pointing more or less straight up. If it isn’t, you can loosen the screw in the center and reposition the knob so it points up, then tighten the screw. You can fine tune the idle screw on the side for best slow idle if you wish. Most people don’t even know it is there.

March 29, 2017 at 1:39 am #55132Why so many motor covers are lost . . . With the cover removed you can see the float pin come up when you turn on the gas. If nothing happens, check the fuel filter. If put away with fuel in the carburetor, it could be stuck in the up position and not letting fuel in. Usually fixed by hitting the primer. Most probable cause of bad spark – dirty points. . . 😀

-

AuthorPosts

- You must be logged in to reply to this topic.