Home › Forum › Ask A Member › Goodyear See Bee 025-3564

- This topic has 28 replies, 6 voices, and was last updated 8 years ago by

frankr.

frankr.

-

AuthorPosts

-

March 30, 2017 at 1:36 pm #55199

Just a follow-up to all the advice I have been given on the See Bee engine. I was able change the mixture of the gas to 16:1 and I turned the carb shut off valve all the way to the left and then primed the engine till I started seeing a little gas on the surface of the water. Two pulls and the engine was running. So I putted around the lake for about 30 minutes and the engine seemed to sputter a bit but I would adjust the mixture and it would smooth out. But for sure, the engine ran 30 minutes and everything seemed somewhat normal.

However, my issues are that everything worked fine until I moved the the throttle to the right past the start position. When I did so, the engine would sputter and die. So I would move the throttle back to the start position and re-fire the engine. So as long as I remained at or below the start position, I was good to go. I tried adjusting the carb shut off valve and mixture settings but nothing really helped the situation.

My hunch is that either I have a dirty fuel filter or a carb setting is not set correctly. Anyone have any suggestions or theories as to what I was experiencing or what I should do next?

Thanks!

RobMarch 30, 2017 at 5:59 pm #55207Probably the fuel filter in the tank outlet is partially clogged and not allowing enough gas to pass through to satisfy the need at high speed. OR, in some cases not enough fuel in the tank (tilted tank and what gas is in there is all at one end—away from the filter).

March 30, 2017 at 7:54 pm #55212The filter in the tank is a very fine mesh little brass sock that sits at end of the copper fuel line. I have the same motor that I restored a few years ago. My filter sock was beyond hope and I could not find a replacement. I put 2 small brass barbed nipple fittings at both the tank and carb end. I then used regular rubber fuel line with a small inline filter from a lawn mower. Had no more issues with filter clogs after that.

March 31, 2017 at 3:41 am #55243ok, I brought the engine home with the intent of cleaning the filters. How do I get into the tank? I see the four bolts (two in front and two in back. I see the brass connect to the fuel line coming out of the tank but do I have to remove the tank and disconnect the fuel line in order to get into the tank?

My other question is can anyone give me some practical advice on how to clean the filter at the carburetor? My uncle told me that they had to clean both filters (screens) to get the motor running again. I have removed the top cover and the two sides. So now I have access to the engine. Show I simply disconnect the fuel line where it drops down from the tank and then remove the tank. Or is the screen I need to close just outside the tank? Sorry for all the questions. It is a really cool engine and I know it fundamentally runs. So if I can clean out the filters and check the plugs, I really think I can open this motor up on the water. Plus, its fun to mess around with this motor. It is fairly simple. Thanks for any additional advice!

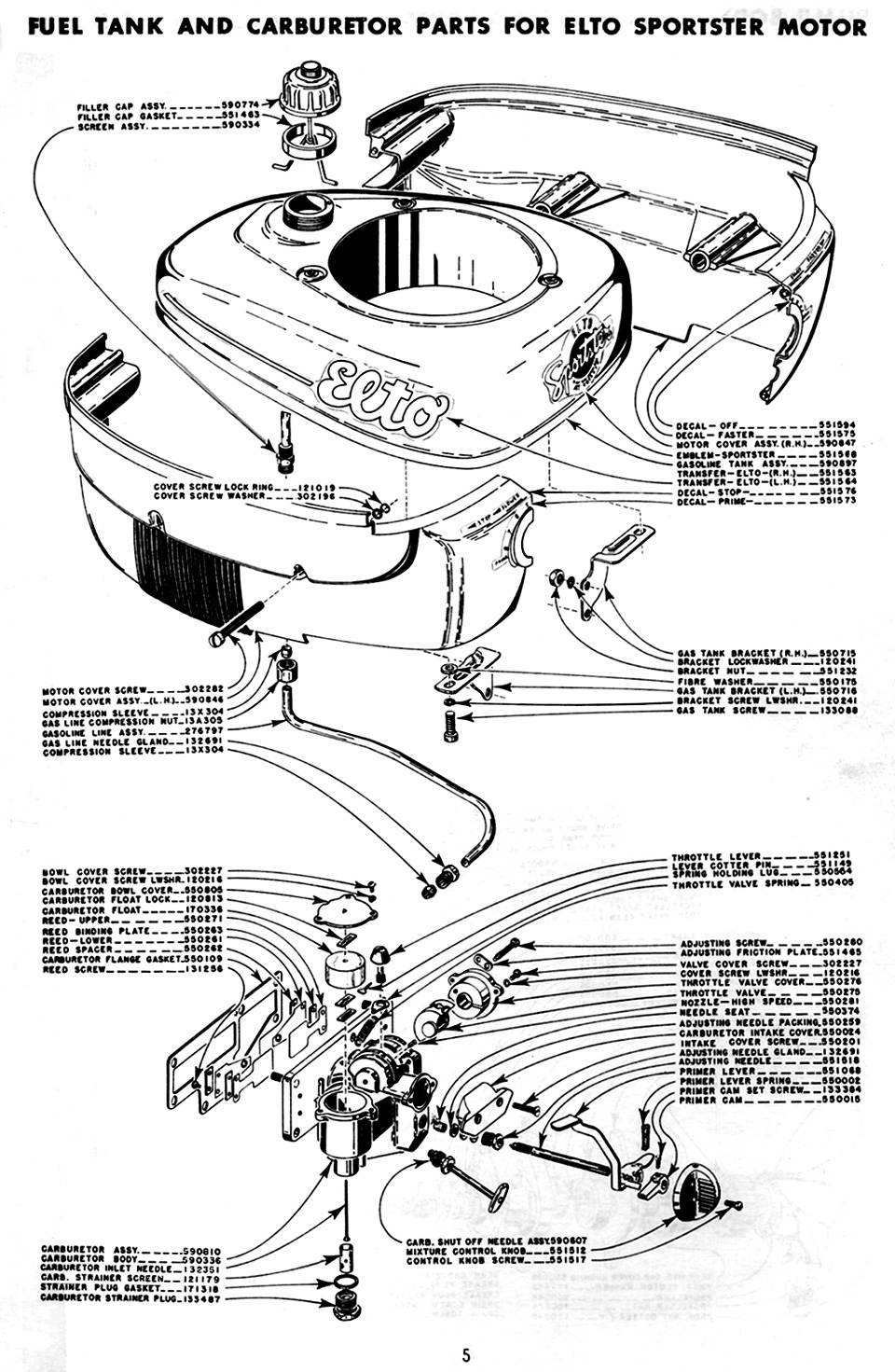

March 31, 2017 at 5:27 am #55247Sorry – Somehow I put page 2 of the parts book in place of page 5 which shows the fuel tank and Carburetor. I have corrected that. . . 😳

The filter in the carburetor is at the bottom of the float bowl.

March 31, 2017 at 6:15 am #55250

March 31, 2017 at 6:15 am #55250Rob, don’t make it so complicated. Remove the copper fuel line then unscrew the filter from the tank.

March 31, 2017 at 6:30 pm #55260Ok thanks. Just a couple more questions since you have been so helpful. I want to replace the gear oil in the lower unit. I would suppose just standard 90 weight marine oil would work? I am used to having a Upper fill hole and a lower drain hole. based on the diagram, I see the gear lube plug. Is that the fill hole? I am used to pumping the gear lube into the lower hole until it starts coming out of the upper hole and then closing the upper hold and at last closing the lower hole. Is it the same for this lower unit? if so, what two holes should I be looking at? Also, I have no extra sheer pins. Are you or anyone aware of where I could buy some extras? FYI, I took the engine cover off and it looks like I should be able to remove the gas tank and clean that strainer and the one in the carburator. What a neat little engine. Thanks for all your help. Your advice has served me well!! Rob

March 31, 2017 at 7:16 pm #55262No, it does not take gear oil, which will leak out almost as fast as you put it in. It takes "Outboard Motor Gear Grease"—no longer made. Most people here use Lubriplate 105, sold at NAPA Auto Parts Stores as "Motor Assembly Grease", OR "Corn Head Grease" sold by John Deere Dealers. Personally, I prefer the Lubriplate simply because it comes in a handy squeeze tube. There is a large grease plug on one side and a small screw-looking vent screw on the other side. Squeeze the grease in the big one till it comes out the small one.

Most of us make our own shear pins.

You seem determined to remove the gas tank. Go ahead and do it if you want. But all you have to do is unscrew the fitting from it.

April 1, 2017 at 12:48 am #55275Thanks again, I am really green about the outboard motor. I am not hell bent on removing the gas tank. I removed the engine cover and did exactly what you said. I removed the gas line and unscrewed the line connected to the tank. I pulled the screen out of the tank. I saw a little stuff on it but not much. I used some compressed air to make sure it was totally clear. I then reconnected it and reconnected the fuel line. I didnt realize that it was a simple task of unscrewing it from the tank. I then unscrewed the carb bowl and checked the screen. It seemed perfectly clear. I air blew it out a little and reinstalled. Not sure if what I did improved the fuel flow or not. I will take it down to the lake this weekend and check it out. Thanks for the information on the lower unit. I had no idea about that. I will look into getting the grease you suggested. Given that I ran for a 1/2 hour on the lake, I am sure it must have grease in there. If my problem isnt better I suppose I will have to take a closer look at the carb. However, it started really easy so I know gas is being processed in there. I really appreciate your patience in helping me learn. My goal is to get this motor ready for steady use in the summer.

Thanks again!!!

RobApril 1, 2017 at 2:26 am #55282A word of caution, You may have observed that the rewind starter pawls on the flywheel protrude at rest. They engage projections on the bottom of the rope sheave. They rarely line ignmentup properly. Attempting to tighten it with the projections against the paws may bend the pawls or loosen the posts the pawls pivot on. Pulling the rope out and letting it retract after gently placing the starter housing on the motor will encourage it to drop properly into place. Also because of variations in producing the various componants (Holes are always slightly oversize) you must always check to be sure the starter is exactly centered over the crankshaft. The center bolt of the starter is hollow and a pointed alignment rod is placed through it to engage the top dead center in the top of the crankshaft. The hole in the housing is large so the center bolt may be shifted to center the rope sheave. . . 😉

-

AuthorPosts

- You must be logged in to reply to this topic.