Home › Forum › Ask A Member › Goodyear See Bee 025-3564

- This topic has 28 replies, 6 voices, and was last updated 8 years ago by

frankr.

frankr.

-

AuthorPosts

-

April 1, 2017 at 2:27 am #55283

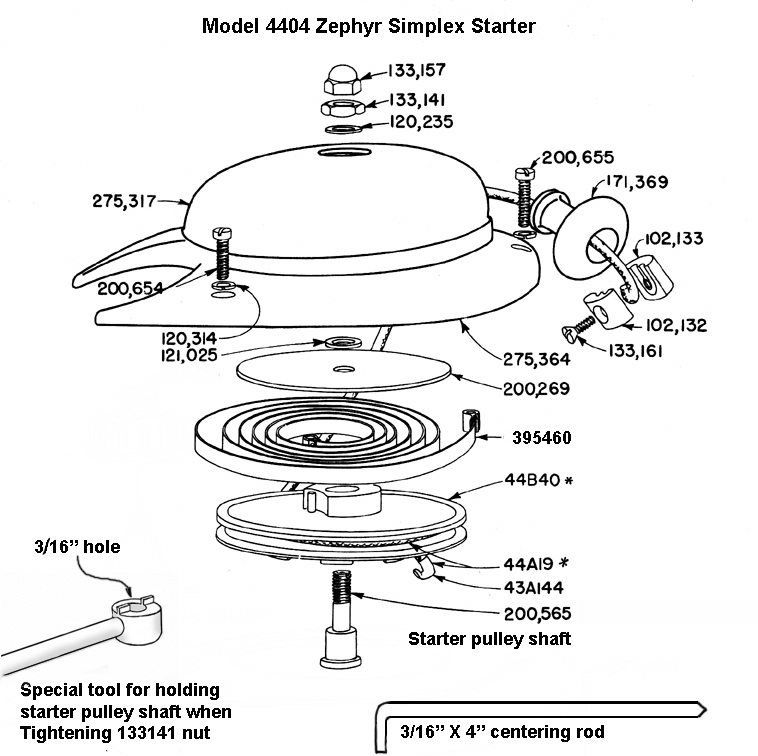

A word of caution, You may have observed that the rewind starter pawls on the flywheel protrude at rest. They engage projections on the bottom of the rope sheave. They rarely line up properly. Attempting to tighten it with the projections against the paws may bend the pawls or loosen the posts the pawls pivot on. Pulling the rope out and letting it retract after gently placing the starter housing on the motor will encourage it to drop properly into place. Also because of variations in producing the various componants (Holes are always slightly oversize) you must always check to be sure the starter is exactly centered over the crankshaft. The center bolt of the starter is hollow and a pointed alignment rod is placed through it to engage the top dead center in the top of the crankshaft. The hole in the housing is large so the center bolt may be shifted to center the rope sheave. . . 😉

April 1, 2017 at 12:41 pm #55293

April 1, 2017 at 12:41 pm #55293Interesting about the "centering rod". I took three of those

starters on the Johnson HD’s apart and back together in the last three weeks,

and never thought twice about the hole in the starter pulley shaft / bolt.

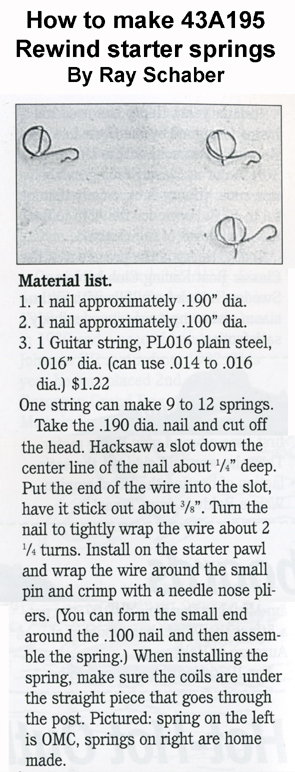

Made some new springs for the first time out of steel guitar strings for the rewind pawls.

I made six springs to get three that I was happy with.

After I installed them on the pawls, I managed to poke a hole in my

finger and blood all over, lol……. those little wires are sharp!Prepare to be boarded!

April 1, 2017 at 7:26 pm #55324On and off isn’t to bad. Replacing the big rewind spring can get you in trouble. . . 🙂

April 2, 2017 at 2:20 am #55351

April 2, 2017 at 2:20 am #55351Well I thought I would give an update on my labor of love of getting this motor running as it should be. First off, I really appreciate all the input provided. I replaced the spark plugs just in case. I was able to remove the screen filter in the tank and cleaned and blew it out with compressed air. It really wasnt clogged. I then dropped the carb bowl and inspected the screen and it was perfectly clean and also in good shape. I put in fresh gas and took it to the lake. There is a lot going right with this motor. I pull, and it started. Unfortunately, I did not improve my situation. As long as I ran at about 50% throttle and somewhat rich mixture, it seemed to run ok. A few coughs but I ran it all over the lake for about 30 minutes. Purred like a kitten at low throttle. So I took the boat in and took off the side panels in an attempt to adjust the carb while I was running. But once out on the lake again, I simply could do no better no matter what I adjusted. If I go above the start level with the throttle, the engine coughs and stops running. My gut tells me that something in the carburator is gummed up somehow and is not letting the fuel to flow when the throttle goes high. So that is my thought. I am going to have to take a part the carb and clean it. Just a note, I could see the float rod coming up when I pressed the prime. So the float I suppose is working?? Does anyone have a step by step instructions on how to clean and adjust the carb on this particular motor? Furthermore, Does anyone have any further thoughts on what my problem is being caused by? Does anyone know of someone in the region of Indianapolis or surrounding areas that my be willing to help me redo the carb or help teach me on doing this? I really feel that this motor is a gem. I just am not sure how to get this accross the finish line. Any suggestions are greatly welcomed! Thanks Rob

April 2, 2017 at 5:53 am #55360Carburetors just don’t come much simpler than the one you have. There is only one metering jet, and it is not clogged or it wouldn’t run at any speed, or change as you adjust it. The cork float is famous for shrinking and sinking, but yours is working (for now, at least). Some people salvage and reseal the cork float, some make new ones out of a big bottle cork, Myself, I make one by modifying a Nitrophyl Mercury float. Those will last a lot longer than I will.

Your symptoms cry out loud and clear. The tank filter is partially clogged. But you say it isn’t. So I won’t argue the point. You are there and I’m not.

BTW, I only have nine Gale motors. And counting.

April 2, 2017 at 6:59 am #55363OK, after pondering on it a bit more, I’ll concede that it is possible that the problem could be within the carburetor. Only a looksee can tell for sure. It may have some gum or varnish restricting the flow between the float bowl and main adjust needle.

April 2, 2017 at 9:07 pm #55397The variety they came up with for one basic engine is astounding. . .

April 4, 2017 at 9:56 am #55519

April 4, 2017 at 9:56 am #55519I wanted to post my progress on my carburator work. I was able to remove the carb. On the carb there is a section which has the mixture up or down adjustment. Does this need to be opened and cleaned? My fear is that I am going to take something apart that will mess something up. Also, the mixture adjustmen knob on the front of the engine (big yellow knob) I for some reason could not come out of the carb. I could unscrew the brass nut but it would not pull out. Is that normal? The main gasket looked good enough. Should I just get carb cleaner and spray all the openings? Then blow it all out with compressed air? The float looked in good condition. I did notice some crud in the carb bowl. I am going to try and post some photos. Any other recommendations on what to open up and clean? Thanks.

April 4, 2017 at 2:06 pm #55533??Could not pull it out?? Of course not, it unscrews to remove. Remove the knob and the little primer doo-hickey and unscrew it. By the up or down adjustment, I’m thinking you mean the throttle shutter. Naw, no real reason to remove it. The main nozzle tube sticks up under it, but you can blow that out via the main mixture needle hole.

You probably are going to need a new packing for the main mixture needle. "Regular" OMC needle packings won’t hold up. I make mine from an old leather belt.

-

AuthorPosts

- You must be logged in to reply to this topic.