Home › Forum › Ask A Member › HD25 shear pin size

- This topic has 12 replies, 7 voices, and was last updated 4 years, 9 months ago by

steveh.

-

AuthorPosts

-

February 7, 2019 at 3:38 pm #166269

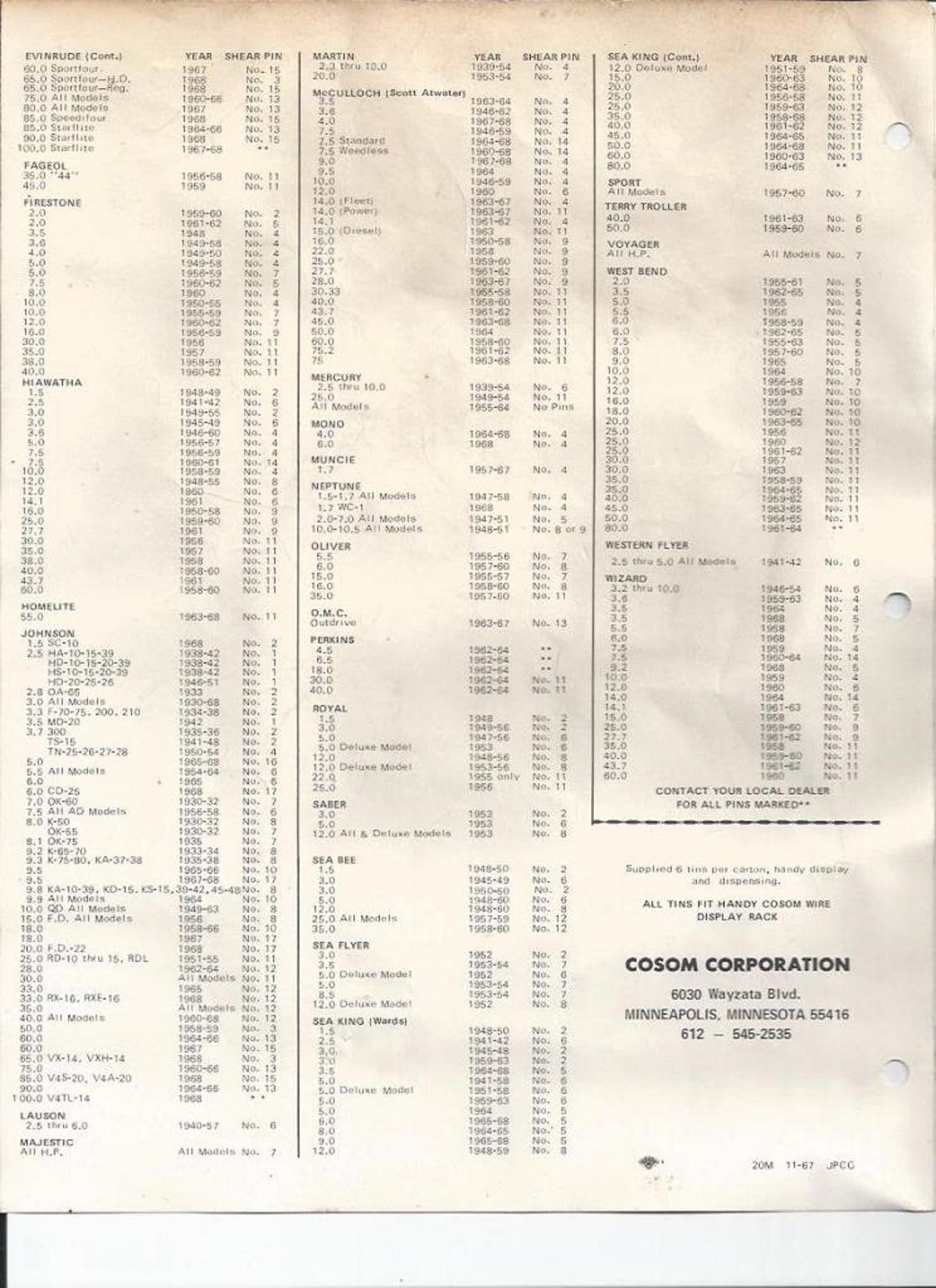

What would be the shear pin size for 1950 HD25? Are some available, or do most make them from rod stock?

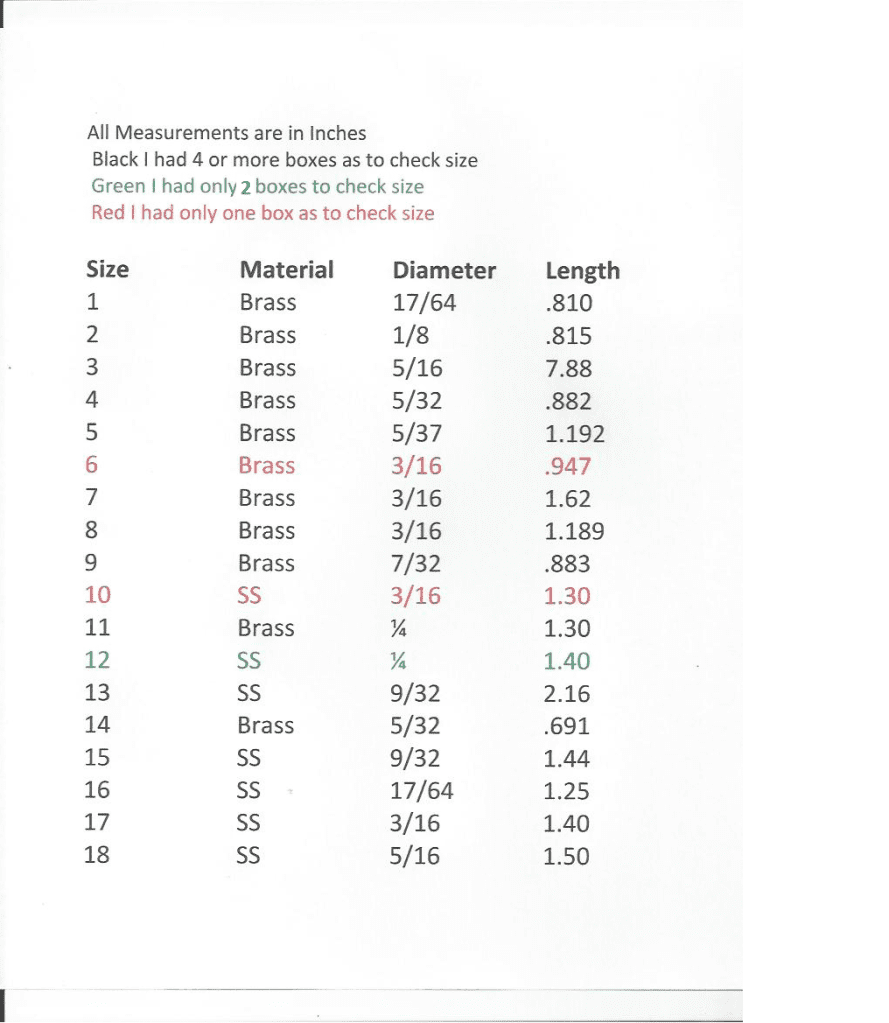

RickFebruary 7, 2019 at 4:45 pm #166274a brass bolt shaft or rod of the proper diameter cut to the proper length should do …

Joining AOMCI has priviledges 🙂

February 7, 2019 at 4:45 pm #166275Part number is 004372. But I can’t find my size chart. I’m guessing (assuming) that they are stainless steel, since the motor has a rubber shock absorber ring in the propeller. Most of us make our own.

-

This reply was modified 5 years, 2 months ago by

frankr.

frankr.

February 7, 2019 at 5:53 pm #166281Looks like a # 6-32 brass machine screw i” long with the head cut off would do the trick.

Thanks for the replies!-

This reply was modified 5 years, 2 months ago by

Rick Robbins.

February 7, 2019 at 6:23 pm #166283The correct current part number is 043072 old 43-72. Shows $2.00

February 7, 2019 at 7:47 pm #166285February 7, 2019 at 7:50 pm #166287February 7, 2019 at 7:53 pm #1662895/32″ appears to be correct.

Prepare to be boarded!

-

This reply was modified 5 years, 2 months ago by

Buccaneer.

Buccaneer.

February 7, 2019 at 10:14 pm #166302WOW, thanks alot for this chart! Much appreciated.

July 19, 2019 at 2:49 pm #179183I was toying around with the idea of using a drill bit, though that would rust over time and is highly inflexible which may cause other things to fail if something goes wrong. In any case, the drill bit that fit the best is a 1/8″, if that helps. I will attempt to find some brass rod stock and cut one to length, or I may go the brass screw route that was suggested above.

otto_my_way

-

This reply was modified 5 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.