Home › Forum › Ask A Member › Head Gasket Material

- This topic has 19 replies, 10 voices, and was last updated 2 years ago by

crosbyman.

-

AuthorPosts

-

January 13, 2023 at 8:58 am #271106

Bucc and Bob, did either of the gasket materials you referenced have a metal core? I have ( from NAPA) some material that should be ideal for head gaskets called ProRamic 2499 from FelPro. It’s rated for exhaust manifolds and has a thin steel core layer with heat resistant fiber layer on each side. It’s 0.064 thick. The problem is that you will not be able to cut it with a knife, a good punch will do the bolt holes, Cutting the shapes necessities, sandwiching between two plywood/ hardboard sheets and sawing, jig saw or hole saw.

I have not personally used it for a head gasket, but looks to be ideal.

Joe

Joe, my gasket material did not have a steel core.

I did read comments about some material that does

have the steel core, and some said, as you,

that it’s hard to cut, and also that the material tended

to separate from the steel core and crumble.I’ve had problems using hole punches on thick, crumbly

material before, especially if the hole is close to an edge.Prepare to be boarded!

January 13, 2023 at 1:05 pm #271110The Cometic material I used did not have a metal core either. I seem to recall seeing that Fel-Pro 2499 product – it would probably work fine but I was concerned about how easy or hard it would be to cut. Guess I could try it.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

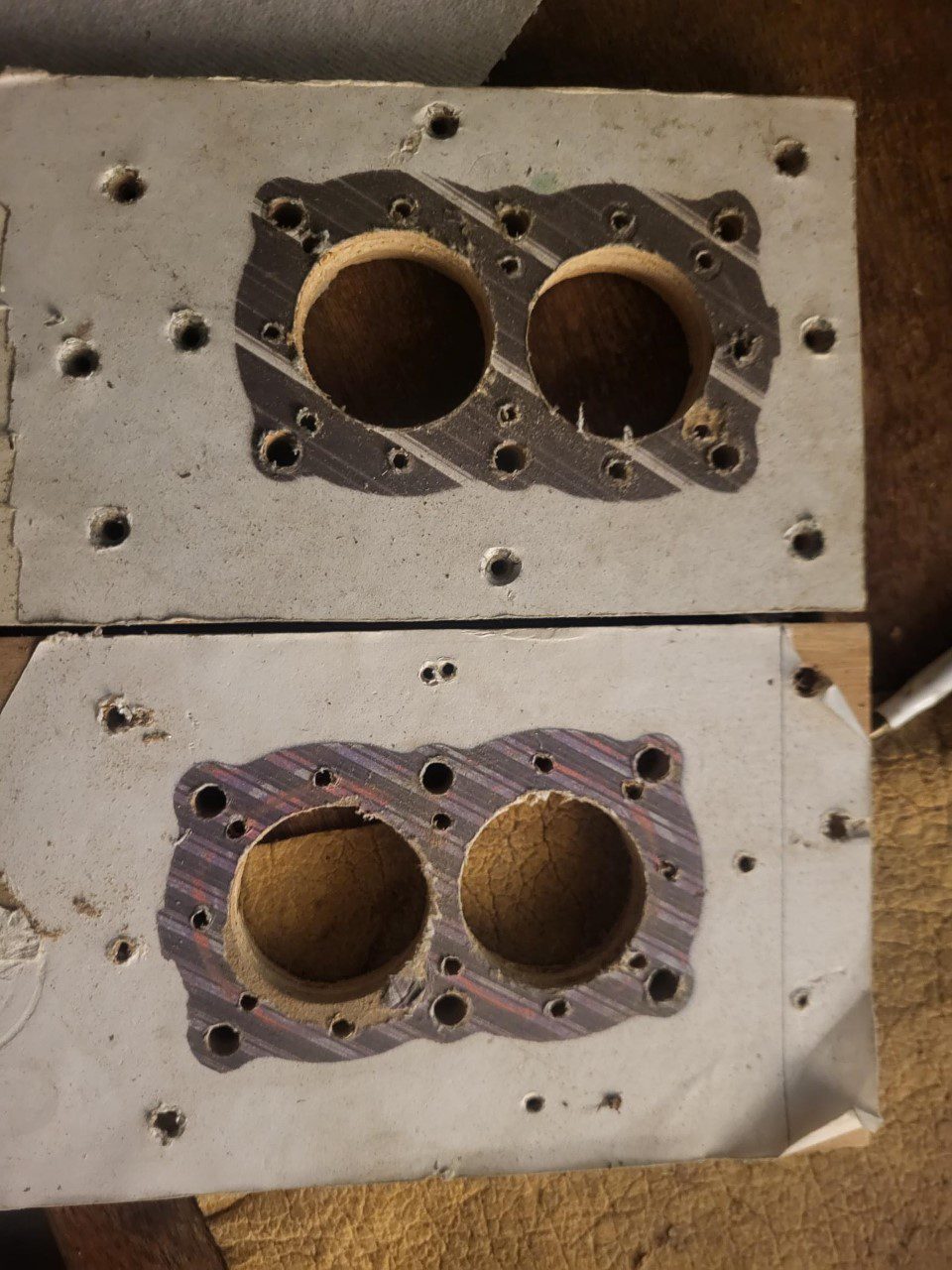

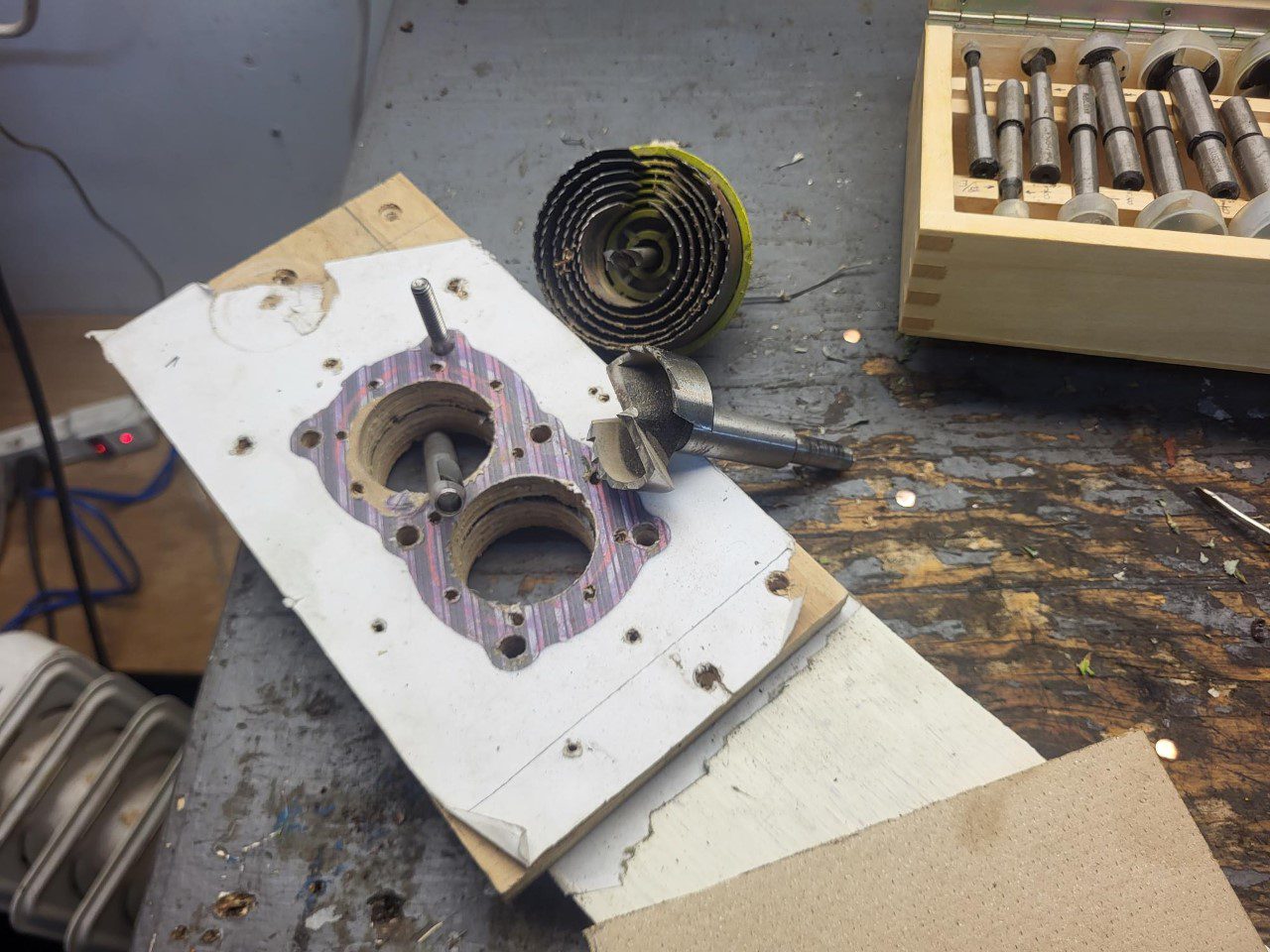

"Every time you remove a broken or seized bolt an angel gets his wings."January 13, 2023 at 5:19 pm #271112This was for a JW or Lightwin .Using metal core gasket material. Really hard to cut by hand.

Photocopy old gasket on desktop printer. Spray glue on to 3/4 inch plywood. If you don’t have a gasket you can copy the cylinder cover. just pack towels around to keep ambient light out.

Screw two pieces of plywood together with stencil on top.

Use drill press to keep everything square.

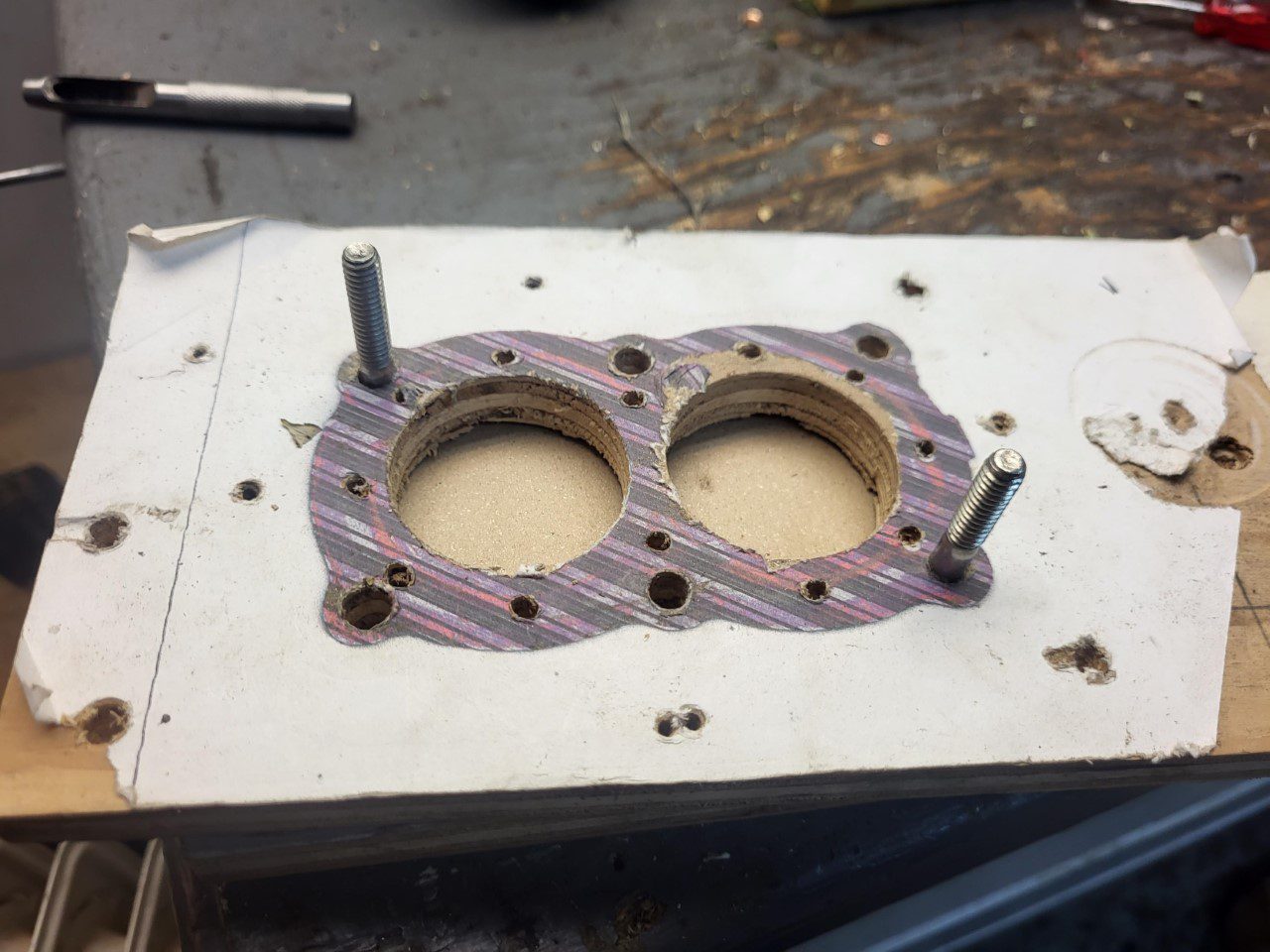

I used a Forstner bit to cut the cylinder holes. Spun it in reverse at first , then in forward thinking it would cut cleaner. Used drill bits, and hole punches for all the water passages and bolt holes. I’m guessing a decent hole saw of the correct size will work too on cylinders.

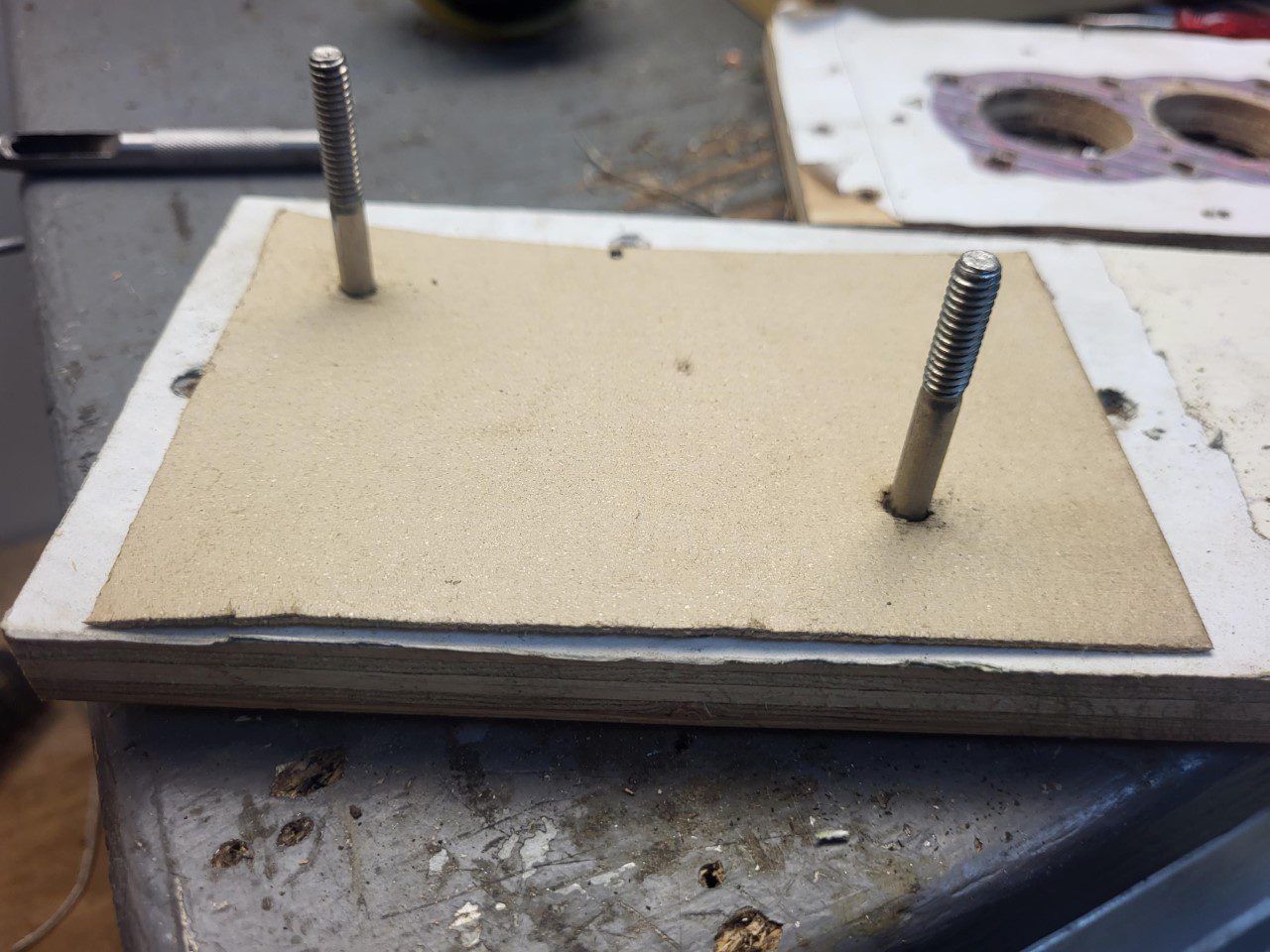

Sandwich gasket material between plywood and locate opposite corners with bolts and nuts to hold the gasket firmly. Then do the rest of bolt holes and bolt them together before cutting out the cylinders with the Forstner.

Maybe a router would work too.

-

This reply was modified 2 years ago by

Mumbles.

Mumbles.

January 13, 2023 at 5:54 pm #271117Wedgie, Looks like it was a lot of work, but turned out okay.

I would have thought someone would be supplying head gaskets for Lightwins

yet, seeing how there’s so popular.Prepare to be boarded!

January 13, 2023 at 6:02 pm #271118To conclude my “Head Gasket” docu-drama series,

I trimmed the OD of the gasket this morning.

The thought came to me laying in bed last night,

pondering if I might have a Dremel bit that would

carve away the excess gasket.I found a “needle” like rotary burr, and it made fast

work eating the gasket as I followed around the head.

I then followed up with a tiny drum sander Dremel

bit to smooth off the fuzzies.Of course, I wouldn’t recommend this method if

you had a fresh painted motor!Prepare to be boarded!

January 13, 2023 at 9:00 pm #271131Of course I could buy one, but where’s the challenge in that ? Actually, I’m really cheap 😉

I had the time and the materials on hand so I figured it’s be worth my while to make a few and use up the gasket material I had. Kind of satisfying to figure out the process . I also have at least a dozen JW ‘s and Lightwins, so worth it to make this jig.

Great idea using the Dremel to fine tune things !

January 14, 2023 at 9:39 am #271139This was for a JW or Lightwin .Using metal core gasket material. Really hard to cut by hand.

Photocopy old gasket on desktop printer. Spray glue on to 3/4 inch plywood. If you don’t have a gasket you can copy the cylinder cover. just pack towels around to keep ambient light out.

Screw two pieces of plywood together with stencil on top.

Use drill press to keep everything square.

I used a Forstner bit to cut the cylinder holes. Spun it in reverse at first , then in forward thinking it would cut cleaner. Used drill bits, and hole punches for all the water passages and bolt holes. I’m guessing a decent hole saw of the correct size will work too on cylinders.

Sandwich gasket material between plywood and locate opposite corners with bolts and nuts to hold the gasket firmly. Then do the rest of bolt holes and bolt them together before cutting out the cylinders with the Forstner.

Maybe a router would work too.

-

This reply was modified 2 years ago by

Mumbles.

Mumbles.

I have attempted to make one gasket out of this material. Whish I had seen

your procedure using the plywood first. Will definitely try it if a attempt to

make another. How did you remove the excess material from the outside of

the gasket.

TubsA "Boat House Repair" is one that done without having tools or the skills to do it properly.

January 14, 2023 at 12:57 pm #271173I got these hole punches from my dad. Most were commercially made. Ones at top were made by dad on a grinding wheel. The small gaskets at side were made to place against old copper and fiber washers on carb bolts of my Elto Ruddertwin. Cork washer is for the carb needle nut. Took two to get correct thickness. Outside and inside holes were made using two different sizes. Tip: make large piece first. Aids in centering inside hole. Samples shown were my first attempts. Believe such punches are still available.

-

This reply was modified 2 years ago by

Mumbles.

Mumbles.

January 15, 2023 at 4:01 pm #271202Tubs,

I used sharp tin snips to whittle away the outside. I’m not too concerned with appearances so didn’t spend much effort making it pretty.

The worst thing about this method is dulling of the Forstner bit.

January 16, 2023 at 10:04 am #271236a router with a straight cutting bit and a template (over the gasket material) to guide the roller bearing would make neat sharp edges.

Joining AOMCI has priviledges 🙂

-

This reply was modified 2 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.