Home › Forum › Ask A Member › Help getting my 67 Evinrude 3hp started

- This topic has 84 replies, 12 voices, and was last updated 5 years, 4 months ago by

reivertom.

-

AuthorPosts

-

February 22, 2020 at 6:15 am #195595

I noticed that the spark on one plug was seemingly weaker than the other. Would that suggest a cracked coil?

February 22, 2020 at 7:21 am #195596February 22, 2020 at 7:42 am #195600Cheers

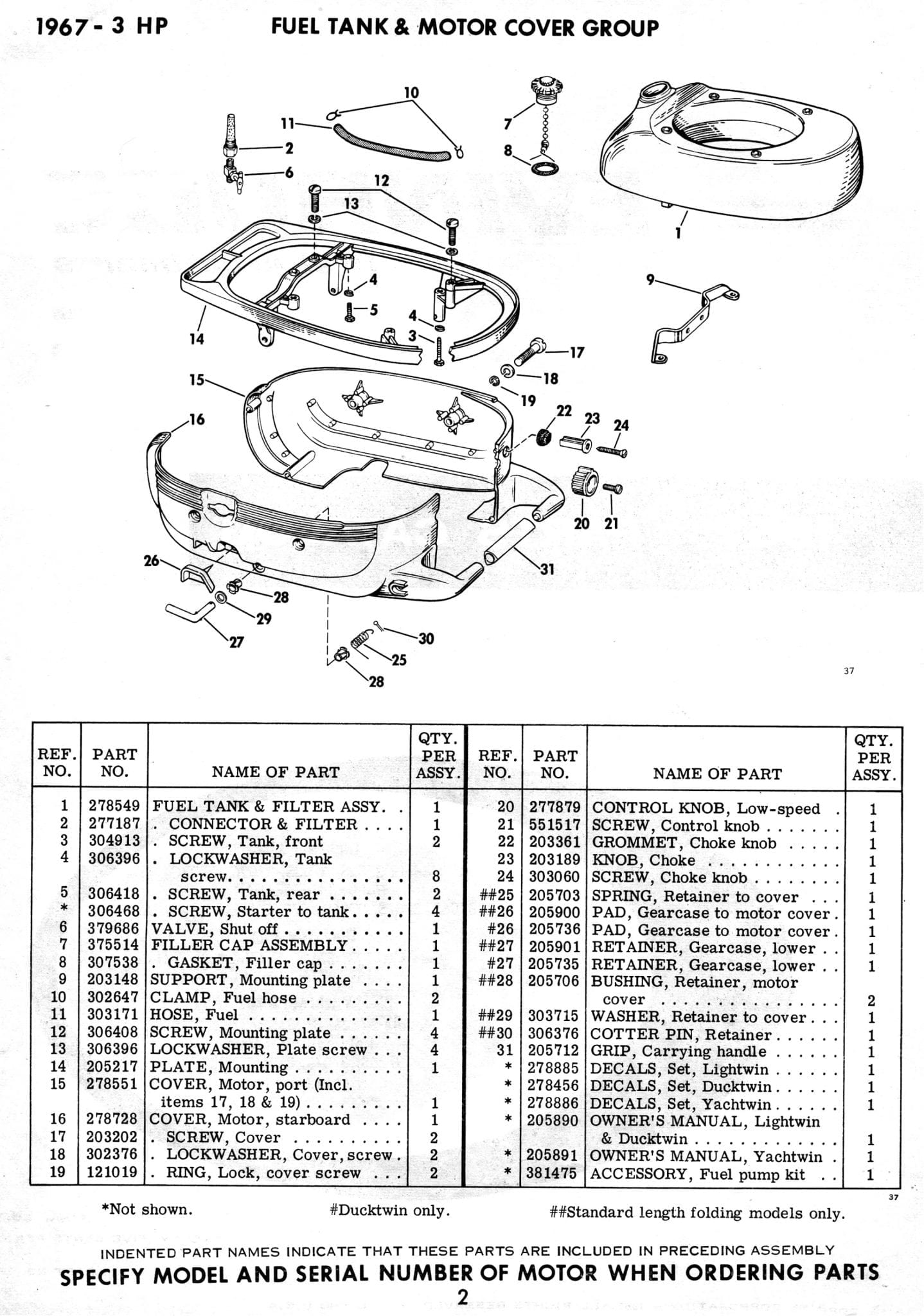

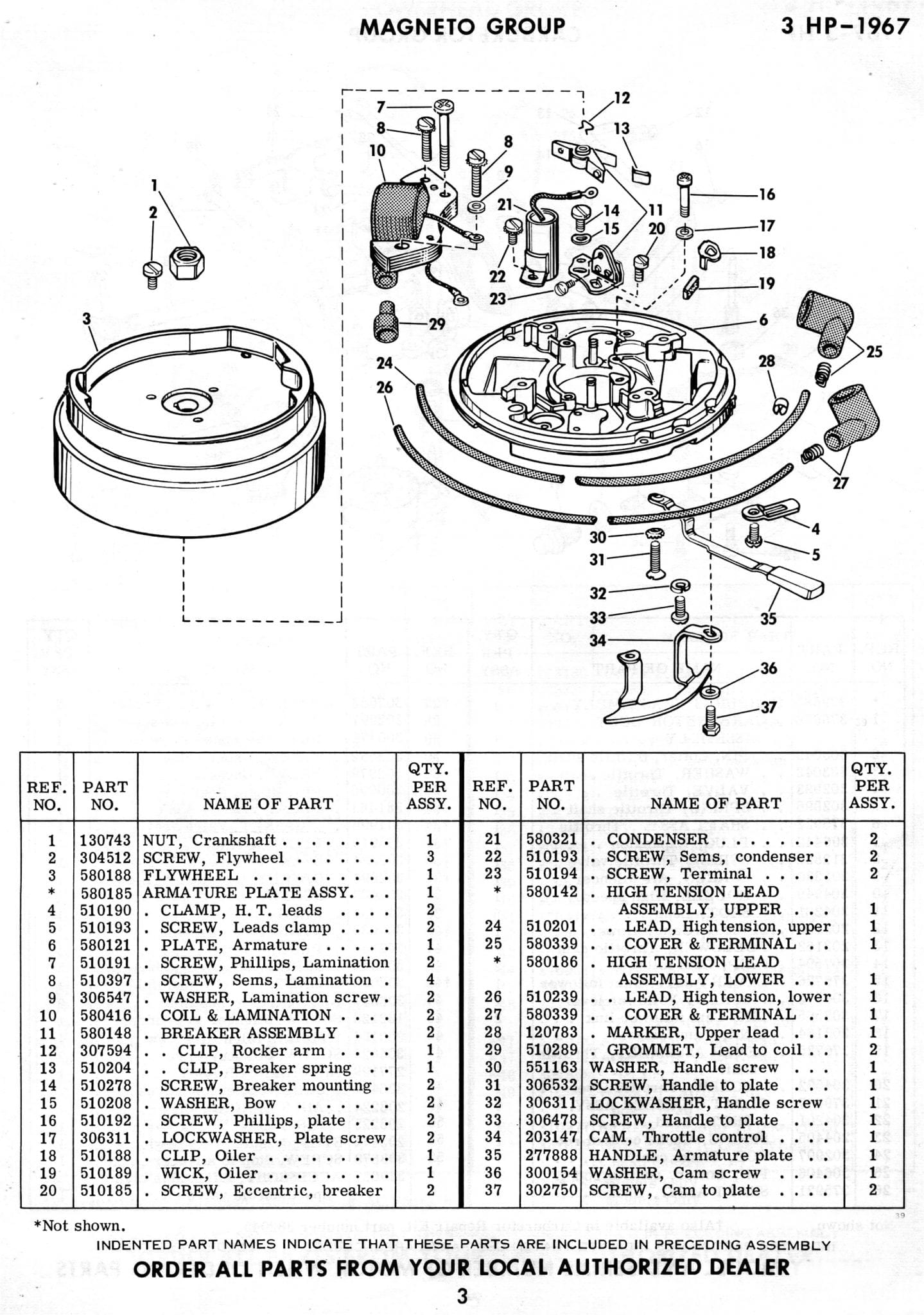

I got the gas tank off earlier no problems. Next I need to get to he coils to check for cracks. The diagrams you’ve provided will help.February 22, 2020 at 8:09 am #195601To check the coils requires flywheel removal. Do I need a puller or is there a trick to getting it off without one? Is this a path I should go down or should I clean the tank, reassemble and cross my fingers? This is all pretty new to me.

February 22, 2020 at 8:22 am #195602I would remove the flywheel for a look-see. You need a 3-bolt puller that uses the three holes at the center of the flywheel. A harmonic balancer puller from an auto parts store will work. Some stores will loan one. A torque wrench to reinstall the nut is also highly recommended. Tighten the nut to 30-40 foot pounds.

February 22, 2020 at 8:40 am #195603don’t forget to clean the 2 vent holes in the tank cap. if you look VERY closely under the cap there is a small metal disk with 2 notches

rotate the little plate and find the 2 holes aligned with the notches then run a paper clip in the 2 holes

with the cap loosened you should see light in the holes

http://www.outboard-boat-motor-repair.com/Evinrude%203%20HP%20Lightwin%20Outboard%20Boat%20Motor/Evinrude%20Johnson%203%20HP%201952-1967%20Carburetor%20Tune-UP.htm

http://www.maxrules.com/fixtuneitup.html

https://www.ebay.ca/itm/Ignition-Coil-Fits-For-Johnson-Evinrude-OMC-Replaces-584477-0584477-582995-CA-/193328227519?hash=item2d0342a4bfbtw gas filtering … you can always hook up a small paper filter on the fuel line to the carb

Joining AOMCI has priviledges 🙂

February 22, 2020 at 11:00 am #195612The guy in the Johnson video totally missed the filter. When he unscrewed the adapter fitting from the tank (with difficulty), the filter was still in the tank. Normally, the filter is soldered to the adapter fitting. On the Johnson video, the filter is stuck in the tank outlet and he tore the solder joint loose as he removed the adapter fitting. On your Evinrude, the filter has come loose from the adapter fitting and was laying loose in the tank, and you fished it out.

Either way, those filters were never intended to be cleaned. You were supposed to replace it, filter and adapter, as a single piece. Yeah, yeah, I know, some people claim they can be cleaned. Whatever. I’m just saying how it is supposed to be.

Your Evinrude probably has crap in the carburetor, keeping it from starting. The fuel has to pass through the main metering jet (orifice plug), which is only about 0.030 inch diameter. Such a small hole is easy to plug up with goop or particles.

What I’m saying is you need to do a complete fuel system cleaning, tank to carb. And put it back together with a good filter

And while you have the tank off is a good time to check the coils. It would be very common to find them cracked.. You are wasting your time until they are replaced, if they are cracked.

Frank, I’m confused as usual….I realize the filter had broken off the adapter and was still in the tank on that Johnson video…I also noticed that adapter came out of the tank with difficulty…Did this guy do something wrong when he removed the adapter??

February 22, 2020 at 11:44 am #195617He did nothing wrong. What was wrong was the filter was crudded up in the tank. It should have come out easy, with the adapter. Probably a load of stale, rotten gas varnish. If it’s any help, I’ve seen a number of them that way.

February 22, 2020 at 7:40 pm #195660There is spark at the plugs and there is good spark. A bad coil will produce a spark with .025 inch gap, but it takes a good coil to jump .25 inch gap. Open up the gap on plugs and see what happens.

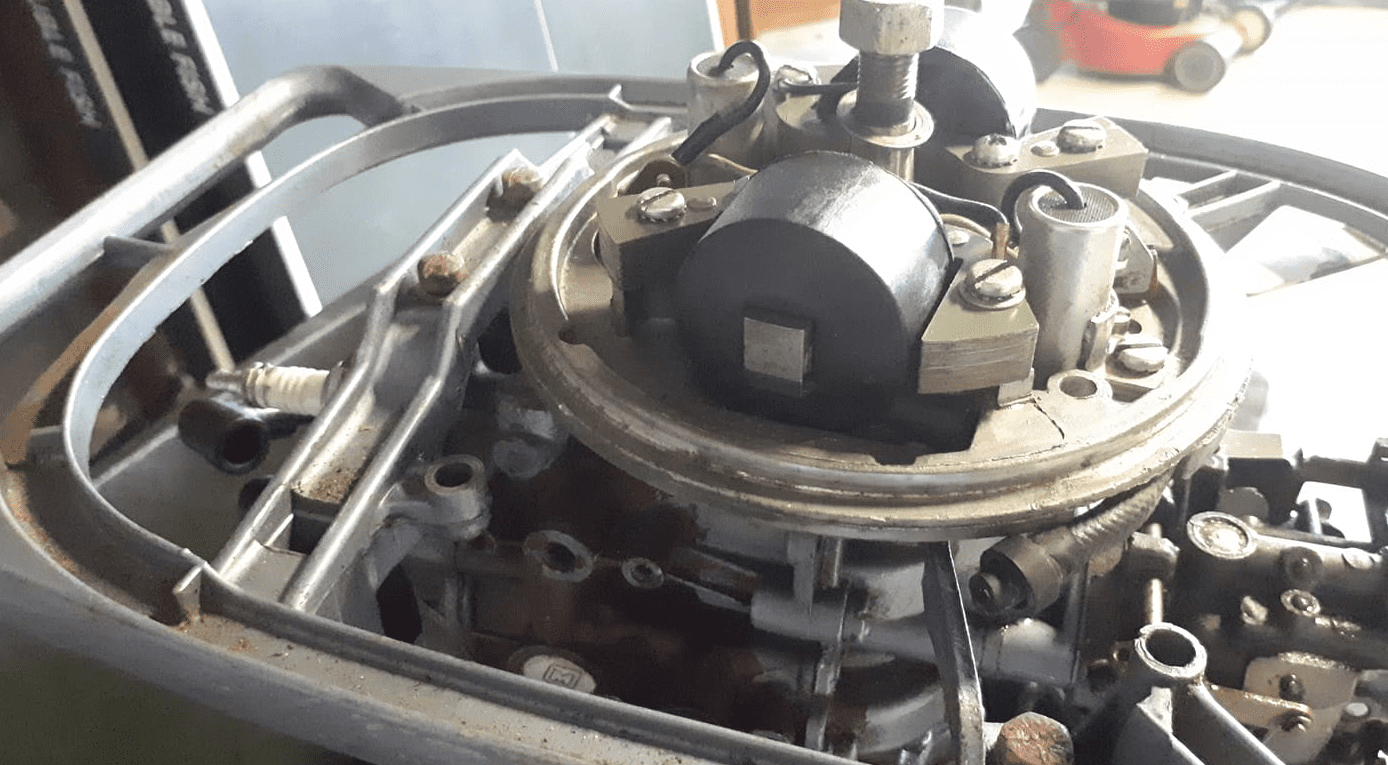

February 22, 2020 at 8:32 pm #195663Flywheel is off.

Both wires on both coils to plug lead output measure 4.75kOhm (which I gather is correct).

Plug lead to upper plug is open circuit (what should the resistance measurement be?) so I suppose there’s my problem.

Where should I get these and are they difficult to replace? -

AuthorPosts

- You must be logged in to reply to this topic.