Home › Forum › Ask A Member › Help with 65′ Evinrude Fisherman 6HP

- This topic has 94 replies, 16 voices, and was last updated 7 years, 3 months ago by

bakercheese.

-

AuthorPosts

-

February 25, 2018 at 7:07 pm #71605quote Mumbles:I don’t think it’s the end of the world if the wick is missing as older vehicles with points went for thousands and thousands of miles with just a light coating of grease on the cam. Periodic resetting or replacement of the points is mandatory anyway.

You know i thought the same thing myself and about just glued the thing where it should sit but its an old family motor that we’ve had since my uncle bought it new in 65′ and as much as I wanted to get it running again and take it out I figured why not do it right since I intend on having it forever…. but trust me the thought was there hahaha

February 25, 2018 at 7:33 pm #71606see picture

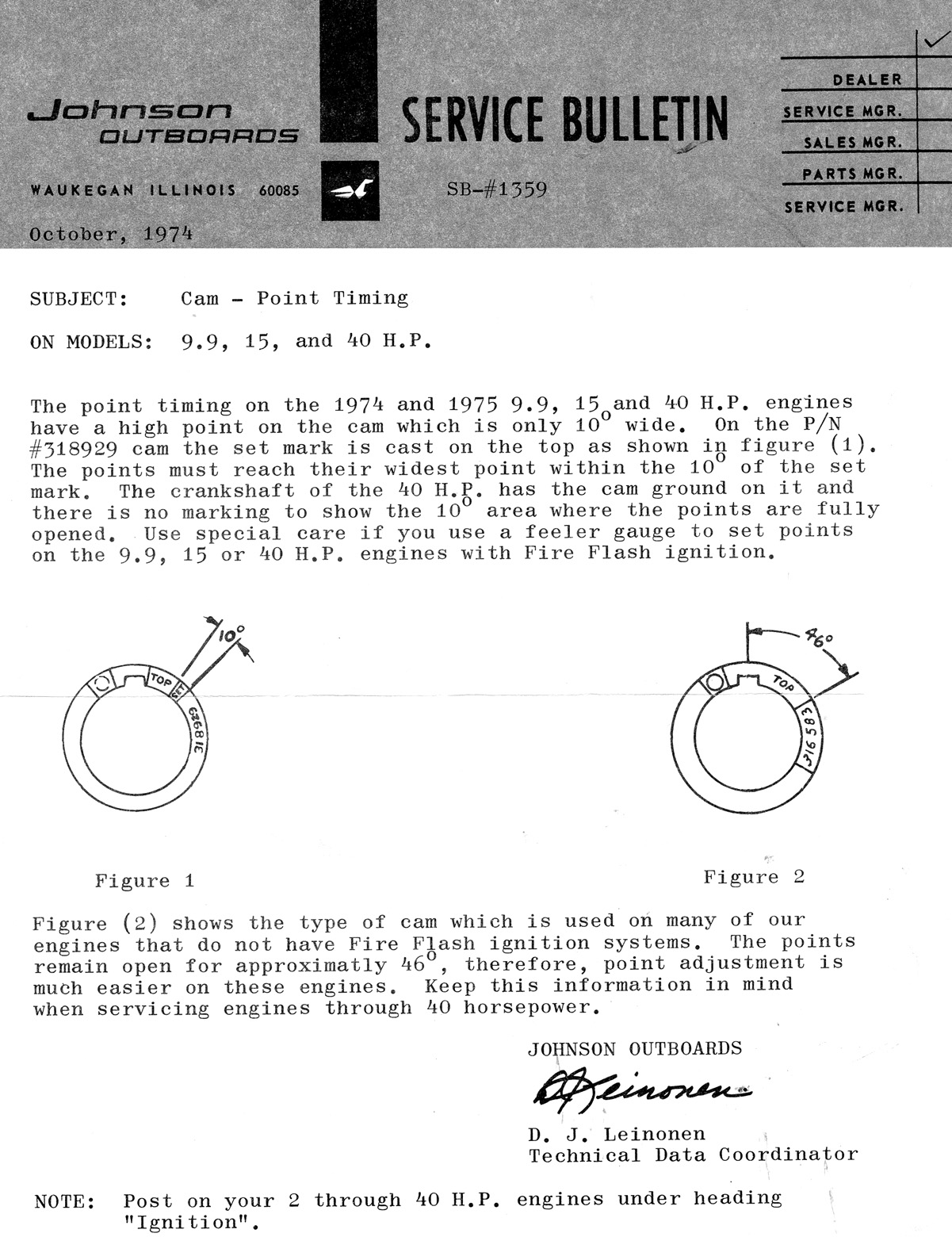

btw here is where I had picked up the habit of using TOP to set my points before using the VOM or with Richard’s (FR) tool

it came from the MAX rule site…

To set the points, move the cam until the point arm follower is touching the cam at the "TOP" embossed thereon. Set them at .020 with a feeler gauge cleaned of all oil with denatured alcohol, acetone or lacquer thinner. The feeler gauge should slip out from between the point faces with a light resistance and the arm should not appear to move when the gauge is removed. Care taken to set the points exactly the same will result in a strong spark and a smooth running engine.

Joining AOMCI has priviledges 🙂

February 25, 2018 at 9:22 pm #71609To find the highest point on the cam, lightly rock the motor back and forth (with the plugs removed) to visually see and feel the highest point. You have 46 degrees to play with so it’s in there somewhere. Just don’t turn the motor too far in its opposite direction of rotation or you can fold the impeller blades over backwards making for more work.

February 25, 2018 at 9:29 pm #71610Thanks Mumbles.. in conclusion seems eye balling is a good start and some tuning after with the "tool" or the VOM 🙂

Joining AOMCI has priviledges 🙂

February 25, 2018 at 9:42 pm #71611If you have the proper tool for setting points there’s no reason to eyeball it then fine tune it, just set it with the tool and ohm meter ond enjoy a fine running motor. And don’t check your gap after, you won’t like it. I’ve had them either to big or both different, but if it’s set to open at the right time and 180 degrees apart, as the factory style tool does, then the gap doesn’t matter. It seems some aftermarket or worn points will do this.

By the way, those 6hp are great little motors. I’ve got Johnsons ‘66 version. It ideas really well with a fine tune up.February 26, 2018 at 2:17 am #71628Thanks again for all the incredibly helpful responses you’ve all been very helpful thank you Mumbles, crosbyman, squier, FrankR, Jerry, indy46 and anyone I’m forgetting! I’m going to go ahead and order the timing tool since it’s the bee’s knees apparently. Should I get the coil tool as well? I was able to get them to line up really darn flush from what I can tell with a straightedge and my fingers.

February 26, 2018 at 2:38 am #71630Agreed squeir that’s exactly what I’d gathered, clean the contacts one last time before you set them, use the tool and ohm meter to set it, then tighten her down, leave it and repeat for cylinder 2.

I know!!! I know!!! 😆 🙂 when I first got it running it was alright, but after a carb rebuild and fidilling with the oil fuel mixture knob had it running great then it lost spark to the top cylinder but before that little thing was kicking ass!!

Any advise on how to set the mixture knob now that I think of it? I cant remember what I read last time about itFebruary 26, 2018 at 3:42 am #71635I set them with the feeler gauge for 20 years before they came out with the tool. I guess practice makes perfect because when i rechecked with the tool, I was dead on. If you have problems it’s usually because of a loose bearing on the crankshaft or breaker plate. . . 😀

February 26, 2018 at 12:17 pm #71642

February 26, 2018 at 12:17 pm #71642make certain no coil wires ended up rubbing on the cam lobe… tuck in all wires away from it

stuff to read

http://www.leeroysramblings.com/OMC_6hp.htm

Joining AOMCI has priviledges 🙂

March 1, 2018 at 8:33 pm #71789Hey all!!

Just wanted to give you guys an update and and a huge thanks to everyone who responded!

Got my timing tool and coil placement ring in the mail Wednesday and got everything times in perfect and put back together last night. Took a couple of pulls to get her going initially but now she fires right up first pull now!Only problem being it SCREAMS like a bat out of hell when it runs in neutral in the tank but after putting it on the boat and running in a lake under power, it doesn’t get going even half as fast as it does in neutral and only seems to be going out about a 1/4 of full power. Seems like it must be a carb issue or maybe fuel/oil screw?

-

AuthorPosts

- You must be logged in to reply to this topic.