Home › Forum › Ask A Member › Here's a Scott-Atwater Question (Bail-A-Matic)

- This topic has 19 replies, 3 voices, and was last updated 1 year ago by

joecb.

-

AuthorPosts

-

November 24, 2018 at 10:18 am #155058

Hello All, On the Scott Atwater Bail-A-Matics with the high-up impellers…..can the impellers be primed by injecting water via the bailer connection? Say I had a squeeze ball and a bit of hose….can I hook it up to the bailer connection and then prime the impellers with lake water prior to start up or immediately after start-up? Has anyone tried that? Seems like it couldn’t hurt to at least get the impellers wet….and seems if they were primed it would mean a shorter time before lake water rose up the tube….

I have heard that there was an article in a past issue of the Antique Outboarder that talked about this but I cannot find it. [/color]November 24, 2018 at 11:31 am #155073I can’t remember that article, but seem to remember reading once

that people used to remove the motor from the transom and

hold it lower in the water to insure the bailer pump was “wet”

for the first start of the day. Sounds like a PITA, and I’d most

likely drop the motor in the lake!

I have two 7.5 Scott’s with the bailer, but haven’t started

on either yet. Will be curious to see what you come up with.Prepare to be boarded!

November 24, 2018 at 4:03 pm #155185Yes, there is a bleed hole between the pumps, so your idea should work to get the impellers wet. Running dry upon startup is the main killer of them.

November 25, 2018 at 7:45 am #155359I have been told that the bleed hole can plug up, which makes me paranoid. I had a couple of Scott 16s, into which I put new impellers at $28 apiece. The whole motor is apparently worth less than the cost of the impellers; so I didn’t want to burn them up. I made a tubular water pick up that I attached to the transom, something like a speedo pitot tube, only bigger. (3/8″) I brought a hose from that into the boat, attached a primer bulb to it and ran the hose back to the bailer inlet, on the leg. I primed the pumps with the primer bulb and went. As I drove the boat, you could see that the bailer outlet was always producing good water. So, it seems like the primer bulb idea works. I suppose that, if the bleed hole really did pug up, the primer bulb would do nothing to prime the cooling impeller. However, on the other hand, it would seem like the cooling pump might actually prime itself better with the hole plugged. Also, a primed bailer pump would help keep the whole pump assembly cool until the main pump primed….Dunno.

I know some guys don’t even run a bailer pump; but my feeling is, where is the challenge in doing THAT?

Long live American manufacturing!

-

This reply was modified 7 years ago by

billw.

November 25, 2018 at 9:13 am #155476I’ve heard of people using blank spool pieces of some kind to replace the

bailer pump impeller. If the impeller is left out all together, does that

affect the cooling pump from working?

Also, has anyone ever tried to re-design the bailer pump with

a hard plastic impeller, perhaps from a 3D printer.

Not sure if it would be possible to make it work, but some how

the metal impellers in the 30’s and 40’s outboards seemed to.Prepare to be boarded!

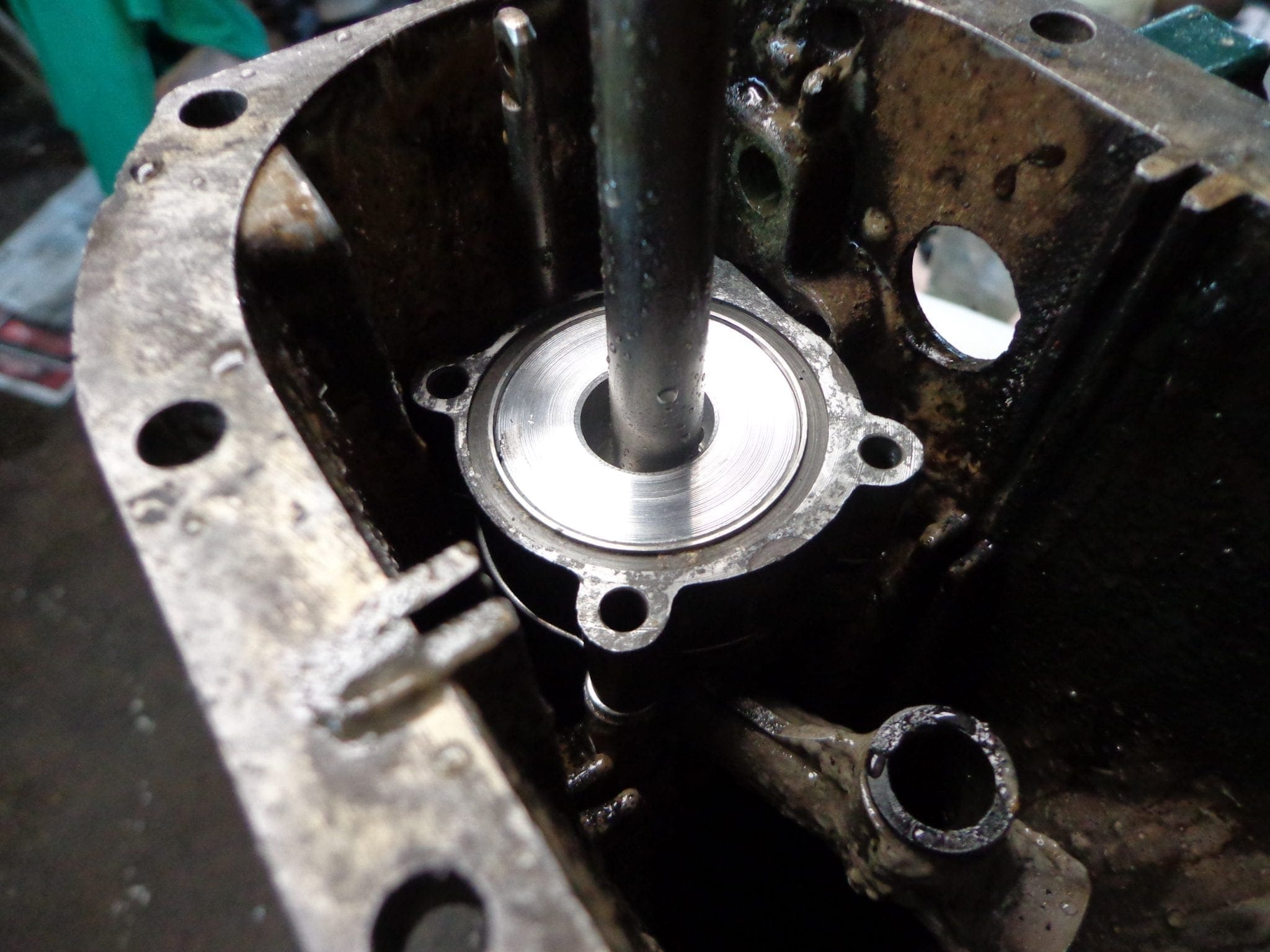

November 25, 2018 at 6:28 pm #155614My ’56 7.5 has an aluminum plug installed to replace the bailer impeller. It’s epoxied in and all the unnecessary holes were tapped and then plugs were installed. I can’t remember if I tried running it without the impeller but it was blowing exhaust out of the inlet fitting on the side before the plug was made. Now it pumps cooling water like a fire truck! In the future I might put it back to original as I have some Honda impellers on hand which are supposed to work.

A hard impeller wouldn’t work as the pump housings bore is offset from the driveshaft centreline and needs flexible vanes to function properly. I do like that thought though!

November 25, 2018 at 6:45 pm #155622Back in “The Day”, I converted a number of Bail-A-Matic pumps to Firestone pumps. Firestone used the same coolant pump, but without the bailer pump stacked on top. The deal included a different cover for the main pump and different wear plate (as I remember it).

Of course, the Firestone parts are probably lost in antiquity now.

November 26, 2018 at 9:18 pm #157216Interesting on the bailer pumps. I’ve never tore into a “bailer pump” motor yet,

but from what I’m understanding, one pump affects the operation of the other?

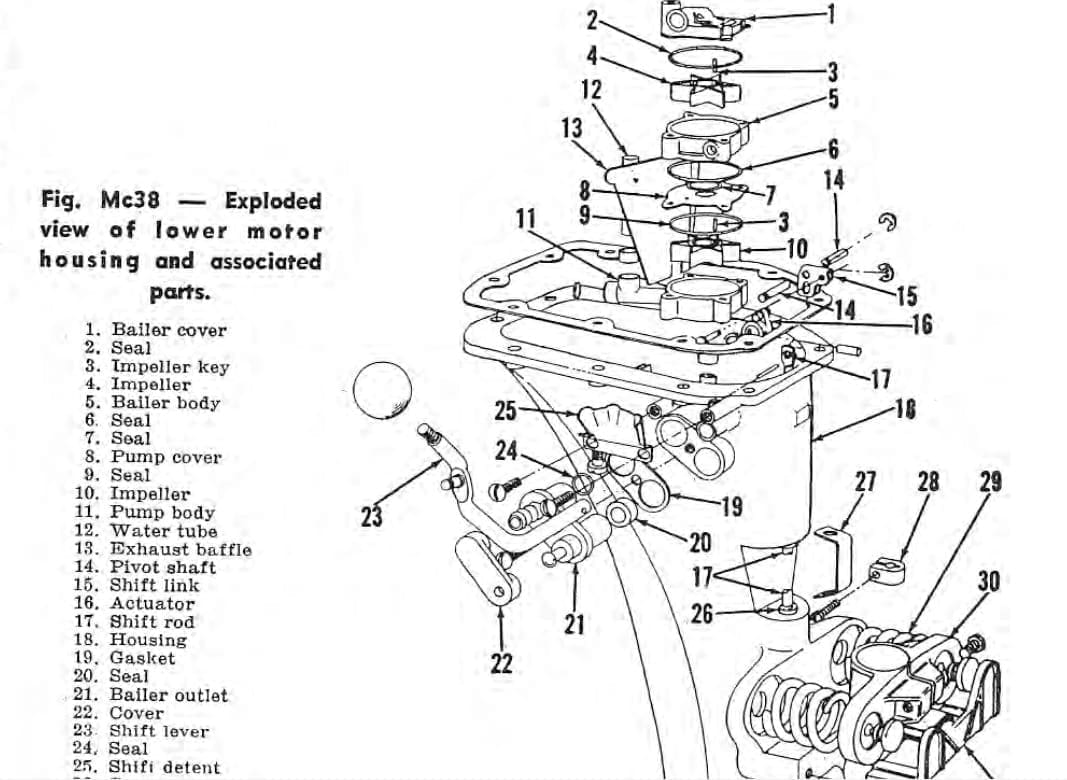

On the parts diagram I found, it looks like they’re stacked together.

Does the bailer pump aid in cooling the motor, acting like a booster pump

for the main?

If anyone knows a part number for the Honda impeller I’d love to know.

I have two of these bailer motors to tackle some day, and one can never

research too far ahead!

Thanks.Prepare to be boarded!

November 27, 2018 at 6:59 am #157283They are two independent pumps, stacked on top of each other. But a bleeder hole between them the allows some water from the main pump to enter the bailer pump in order to keep it from running dry when not bailing.

November 27, 2018 at 8:01 am #157284Maybe I’ll get this figured out yet. Sounds like the bailer pump is not a booster

for the main pump, and that it would have a separate discharge overboard

just for pumping out that leaky boat. Does the bailer pump always spit

a little water out the discharge, supplied via the bleeder you mention?

I may have to tear into one of these for my next project out of curiosity.

Thanks!They are two independent pumps, stacked on top of each other. But a bleeder hole between them the allows some water from the main pump to enter the bailer pump in order to keep it from running dry when not bailing.

Prepare to be boarded!

-

This reply was modified 7 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.