Home › Forum › Ask A Member › Holes in starter motors and oil seals

- This topic has 5 replies, 5 voices, and was last updated 5 years, 1 month ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

November 24, 2019 at 12:36 pm #187958

If I promise to seal them up cleanly with some epoxy, how big of a no-no is it to drill as small as possible holes (4) in the bottom of a starter motor for a 77′ 35 hp evinrude? This being done to insert wires to hold the brushes. Or, is there a tool to hold the brushes down and in place as one reassembles the motor?

Or, is there a cool trick to it?

And, is it okay to use oil seals from a mail order catalog that may or may not be designed specifically for outboard use? Assuming they fit as they should.

My concern is the psi rating.

The ones I see are rated to hold 10 psi.

Have no idea what psi I’m dealing with in a typical old classic omc 5-35 hp gearcase, water pump or powerhead.

Also, if it’s legit to use them, does the labeled inside diameter have to be same as the actual diameter of the shaft it’s to fit around or should that labeled inside diameter of the seal be smaller than the shaft to be snugly.

For example, the propeller shaft is 3″ diameter. Should the labeled inside diameter of the seal be 3″ too, or like 2 and 63/64ths, or some such number smaller than 3″.

Or, how bout this, is there a resource that will tell me that a cd-12 requires a prop shaft seal with 5/8 I.d. And a 1 1/2 o.d.?

The reason I ask is because I’m getting into just diving into motors and trying to get them going with out having to take them apart, figure what all I need, order said parts from Jeff, then wait a week and a half to put it all back together by which time I’ve started another one and mixed up parts….yadda yadda yadda.

I’d like just to get a butt-ton of them in varying sizes and just have them and grab them.

Same goes with spegetti seals, but I’ve already ordered like 400′ of that so I’ll learn soon enough.

Hmmmmm

Shore would know I’ve got the right one if Jeff sent it.

Hmmmm

GJMGP

November 24, 2019 at 12:58 pm #187961November 24, 2019 at 1:01 pm #187964Oh hell yes!

Perfect.

GJMGP

November 24, 2019 at 6:47 pm #187988Geer, you need to come by my shop! I know I’m not available most of the time, but call me in advance when you’re into something pressing and I’ll take time. All that stuff you’re bogged down with is easy to solve.

george

November 25, 2019 at 7:46 am #188009I wouldn’t mess around with non OEM seals, especially if they are not brass or SS. I’m sure it is OK to “substitute” if the manufacturers numbers on the seals/bearings agree with the original seal….

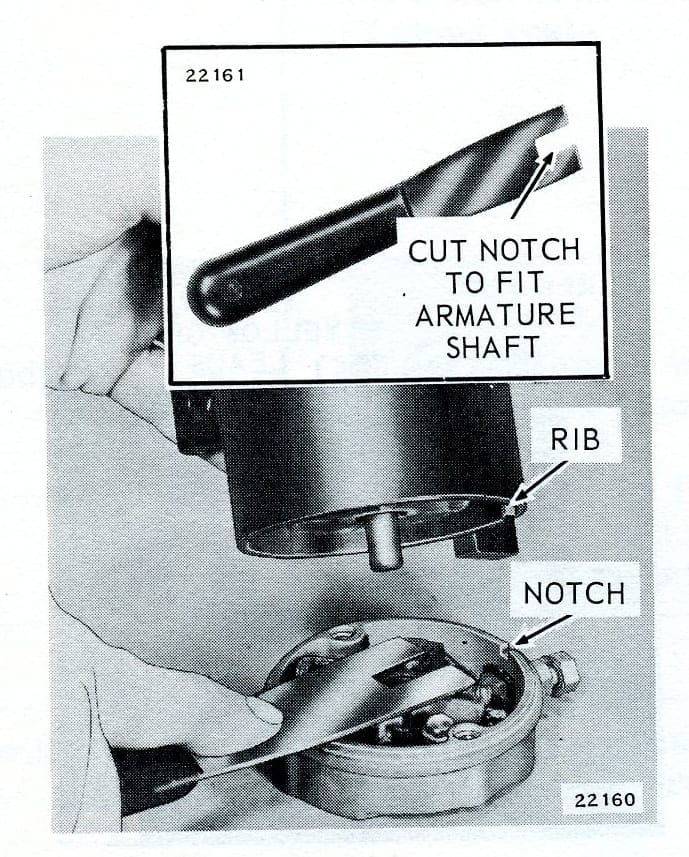

November 26, 2019 at 3:38 pm #188085Here’s a little tool I built years ago to hold those pesky starter brushes in place while assembling these style of starters. It’s just a thin piece of aluminum with a slot cut in it to clear the shaft and it slides over the end cap. Once the cap has started on the shaft, it is simply pulled back out. The beauty of it is you can load the brushes and springs into the end cap, slide this thing over it and put it away until you are ready to work on the starter again.

-

AuthorPosts

- You must be logged in to reply to this topic.