Home › Forum › Ask A Member › How do I get the needle valve bushing back in?

- This topic has 9 replies, 5 voices, and was last updated 5 years, 5 months ago by

huntleybill.

-

AuthorPosts

-

November 14, 2018 at 8:27 pm #151134

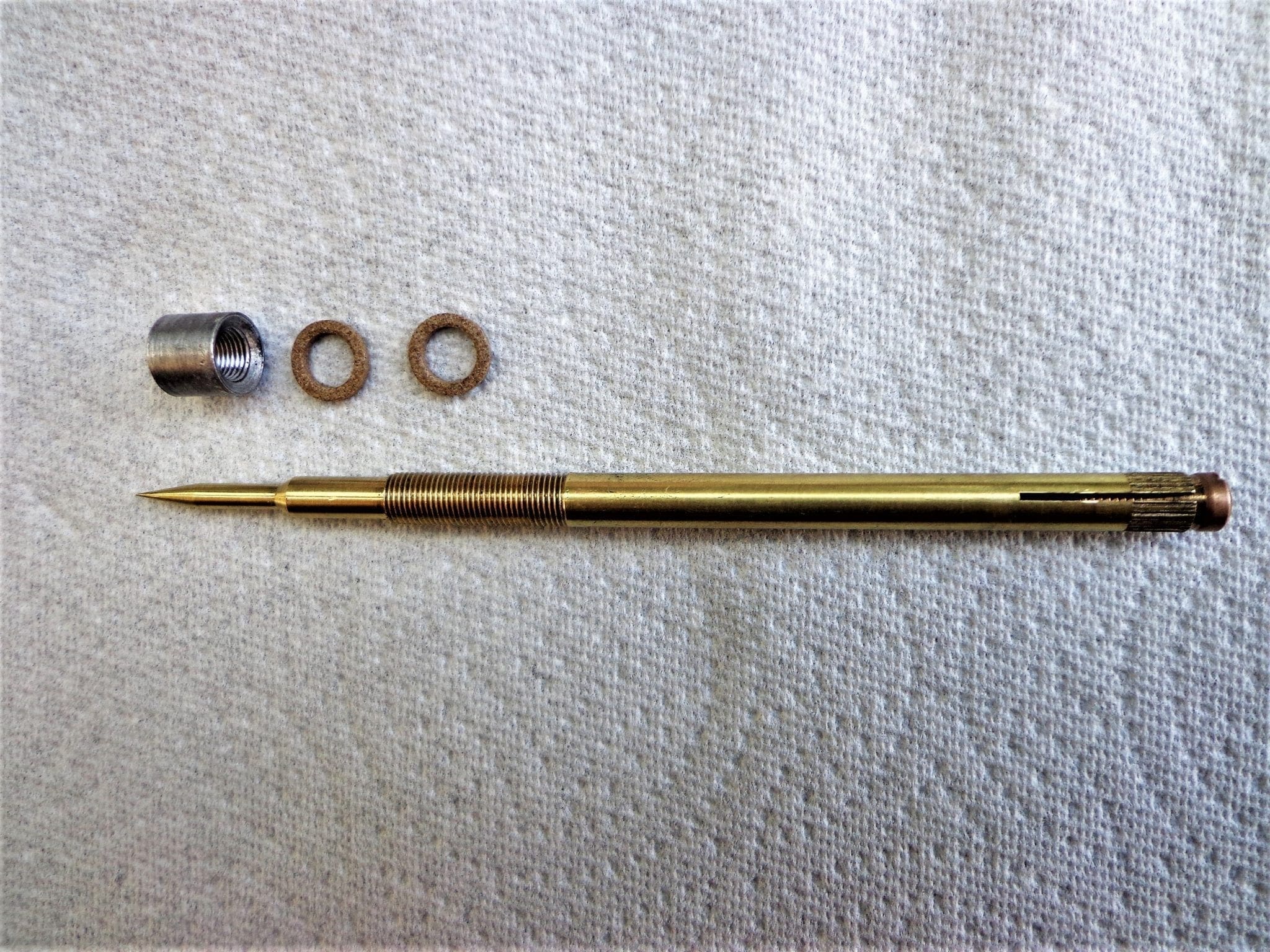

Was cleaning this carb and the bushing and needle came out together. How should it go back in? Can I use loc -tite? or is there something better? ..or?

Your advice would be appreciated.

Thank you

BillNovember 15, 2018 at 6:23 am #151384You just simply push it back in. That’s it. The friction of the lock screw keeps it from spinning.

November 15, 2018 at 4:38 pm #151565Lock screw???? Oh… you mean the brass nut that also holds in the fiber washers? I wasn’t aware that this bushing should come out that easily but ok, thank you for the input. I will push it back in.

November 15, 2018 at 7:04 pm #151595Yes, the packing nut holds that sleeve in place. Sometimes they fall out and others are in there really tight. The packing and packing nut will hold it in place though.

-BenOldJohnnyRude on YouTube

November 16, 2018 at 10:18 am #152048I’ve struggled with this…..

– With the packing sleeve-nut tight on the packing washers, the needle won’t turn.

– When I loosen the sleeve-nut so that the needle will turn, the bushing turns with it, so no carb adjustments are actually being made.

I had spare carbs for my engine, so I just substituted another carb. If I had to fix the carb with the loose bushing, I don’t know how I would have fixed it.

November 16, 2018 at 10:37 am #152072If the threads get too sticky that can be a problem. I have had that problem as well. I have had to remove the packing washers and soak the needle and sleeve in PB Blaster and give them a little shot with the heat gun to get them loos enough to start moving again. Once it is off there, clean the threads the best you can inside the bushing and the outside of the needle before putting it all back together with new packing. You may have to put the control knob back on to be able to turn the needle once the packing nut is tight enough to hold the sleeve stationary. I have heard to not use any kind of locking compound on the sleeve, but I really don’t understand why not to. as long as you use care to not get it in the threads. I’m not recommending using Loctite on the outside of the sleeve, but I do not see how that would negatively affect anything. Maybe someone can explain that to me so I understand it. As far as I can tell, they carburetors were made this way just because cutting the threads that close to the needle seat is not practical. It is much easier to just drill the hole and insert the sleeve during assembly. If the sleeve was permanently affixed inside it should have no negative effects on the function of the carburetor.

-BenOldJohnnyRude on YouTube

November 21, 2018 at 9:26 am #154297OH OH fisherman6, I read your reply too late. I used loctite to hold the bushing in being careful to use as little as needed and wiping any excess out that got in the threads. I then let it sit over night. I put new packing and inserted the needle. I have not put the carb back on the motor yet to see how it runs, but the needle seems to turn snug without the bushing spinning.

Hope I didn’t ruin it!

November 21, 2018 at 11:49 am #154330Huntleybill, I think you will be fine. As long as you are able to spin the needle freely I cannot see how the locking compound will have any adverse effects when used in the way you described.

-BenOldJohnnyRude on YouTube

November 21, 2018 at 12:06 pm #154339If the threads need chasing and you have the tap and dye handy, the threads are 1/4 -40. The concave side of the bushing faces out, towards the packing washers and gland nut.

You’re lucky yours came out. Quite often heat is needed to free them up.

November 23, 2018 at 9:58 pm #154901Not sure I can call it luck. It just fell out!!

-

AuthorPosts

- You must be logged in to reply to this topic.