Home › Forum › Ask A Member › John Deer Corn Head Grease

- This topic has 17 replies, 11 voices, and was last updated 3 years, 2 months ago by

billw.

-

AuthorPosts

-

October 17, 2022 at 6:12 pm #267815

I have a Johnson TD20 and a HD25. Considering changing lower end lube with corn head grease. An opinions. Good or no Bueno.

October 17, 2022 at 6:46 pm #267817non shifthing gearcases can use it as I recall.

Joining AOMCI has priviledges 🙂

-

This reply was modified 3 years, 2 months ago by

crosbyman.

October 17, 2022 at 7:19 pm #267824Better to stay with 90 wt gear oil. Any water will sink to the bottom and easier to change when needed.

October 18, 2022 at 10:26 am #267846

Corn head grease and 105 are used as a replacement

for the grease that is no longer available used in the

early motors that didn’t have seals. Gear oil is a better

choice as it can more easily circulate through the

bushings and bearings providing better lubrication

when you have seals that keep the water out.

Tubs.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

October 18, 2022 at 11:12 am #267848Here’s my take on this subject. JD Cornhead grease is a readily available NLGI#0 grease. I have been recommending it for quite some time to be used in non-shift outboard gear cases. The reasons are simple. It protects the heavily loaded surfaces of the gears and bearings when it has been diluted with water. Gear oil simply does not serve well when water enters the system. In addition, the thicker consistency of the grease serves to resist the intrusion of water past compromise seals. I have assembled hundreds of racing gear cases for racers and hobbyists, and it has been proven time after time that the NLGI #0 grease that I have been filling the quicksilver with provides the best protection for gear life. #0 grease is simply the thinnest grease. Thinner is oil. The grease that I use contains an Extreme Pressure Additive that serves to separate the heavily loaded gear contact surfaces. I have observed less wear when the grease is employed versus the finest of gear oils such as Mercury’s High Performance #90 gear oil. When water invades the oil, it easily separates as it rests. Areas of the steel gears and shafts exposed to the water rust when allowed to be exposed for a period of time. When the Corn Head grease is used, and water intrudes, it forms an emulsion that continues to protect under load and at rest. So, use the oils in shifter units, and Corn Head in the others. And, by the way, Lubriplate 105 is assembly lube, not meant for LU use. It simply comes packaged in a simple to use tube, and has no EP component. Have fun Boating. R.T

October 18, 2022 at 12:06 pm #267850General rule of thumb is, if the non shift motor came with seals on the drive and prop shafts, gear oil is the preferred way to go. Gear oil is neccesary on the Evinrude Sportsman/Sportwin motors equipped with seals and which have a ball bearing on the driveshaft directly below the water pump which needs oil to lubicate it. Grease of any kind will not be able to make its way up to this bearing. I’m not sure if the HD motors are equipped with this bearing or not.

JD Corn Head grease liquifies when worked so it will find its way into bearings and bushings just like oil will but a heavier grease can not. Gearcases without seals will allow oil to drip out and water to come in while the JD grease will not drip out as it solidifies slightly while sitting. Badly worn bushings on the shafts will aggavate this problem. Any water making its way in will be emulsified with the grease while still allowing the grease to lubricate the parts between servicing.The Corn Head grease isn’t recommended for any FNR shifting gearcase because of the way they are designed. They need oil to do the job.

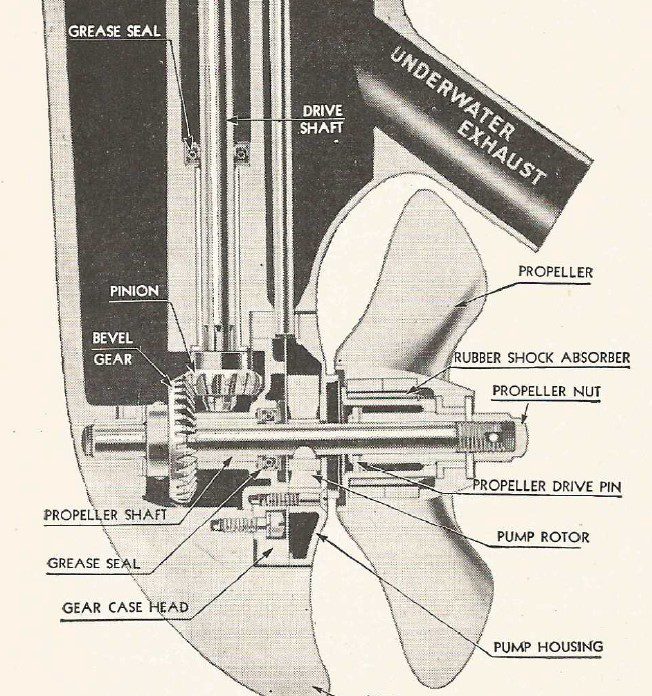

If the gearcase has a vent plug on the side and quite high up, then it definately takes oil. This diagrm of a TD gearcase shows seals on both shafts so I’m assuming it requires gear oil, same as my TN’s do.

October 18, 2022 at 12:33 pm #267853

October 18, 2022 at 12:33 pm #267853

I cant agree more with foot_doctor statement about the affect water has on gear

oil as well as your comments as to the better protection grease provides if water

is present.

Due to decreased demand it is no longer being packaged as such but 105 was

the first substitute for the gear greases that are no longer available and was being

use long before corn head grease. Corn head grease has never been sold as a

outboard motor gear lube as far as I can tell but serves well as an economical

substitute.

105 has Zinc. This is the high pressure additive used to protect the bearings

and especially the flat lifter cam shaft at startup of a fresh motor. I believe having

this additive in the gear case may be beneficial to the gears as there must be a

considerable amount of pressure on them especially under hard acceleration and

makes it a better choice than corn head grease “for me”, in spite of the expense,

for the motors I use it in that don’t have seals.

If I had the capillarity to install seals in my early motors that require grease I

would then switch to gear oil for the reasons I stated above.

Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

October 18, 2022 at 12:58 pm #267854mumbles…This diagram of a TD gearcase shows seals on both shafts so I’m assuming it requires gear oil

odd your picture calls them grease seals …:-)

Joining AOMCI has priviledges 🙂

October 20, 2022 at 8:57 am #267932I have a early 60’s Mercury 450 that I use on my fishing boat. I was getting water in the L/U so I put grease in it just to get me through the summer. 20 some years latter it is still using grease with no problems. I started with 105 and changed to corn head a few years ago. Mercury recommended grease in all their motors in the 50’s, shift and non-shift. Not saying others should do this, just letting you know my experience and an option.

October 22, 2022 at 2:18 am #268025I have not tried Corn head grease in my OMC lower units but my brother has been using it for the past 10 years in a fnr Mercury 9.8 and a fnr Johnson 6hp.

-

This reply was modified 3 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.