Home › Forum › Ask A Member › Johnson 5.5 won’t idle

- This topic has 20 replies, 9 voices, and was last updated 2 years, 8 months ago by

Steve D.

Steve D.

-

AuthorPosts

-

April 4, 2022 at 11:27 am #257458

Had a 1959 Evinrude Lightwin that ran well at first, then wouldn’t idle like your motor. The problem was that the points set screw rotated just a bit on one set of points, and the timing was thrown off. Just needed to reset the gap, and used a little more torque on the set screw.

It may pay to revisit the ignition assembly. Once that is checked, the link and synch adjustment is important to achieve the proper relationship between fuel supply and timing.

Good point, make sure the carb butterfly is closing properly and the throttle shaft isn’t jammed.

April 7, 2022 at 7:23 pm #257667Low compression 60 psi or less will cause bat idle

August 22, 2022 at 1:11 pm #264724Thanks for the reply. I think the excess fuel check valve purge may be where I look next. I’ve attached links of the motor running in a barrel. The points have checked spot-on at 0.020″. Really three symptoms here.

1. Motor does not idle well

2. Motor smokes excessively. Oil mixture is the recommended 16:1. The smoking is new.

3. Seems to be some faint knock.

Thanks for all the advice.

Buster

August 22, 2022 at 2:37 pm #264727Engine knock sound like you make have a bigger problem. Did you check the pistons for too much play?

August 22, 2022 at 4:36 pm #264737In your video when you are slowly pulling the recoil, the armature plate is moving which might be from a coil heel sticking out too far and catching the inside of the flywheel. That in turn may be causing the armature plate to move and lower the throttle, to the point it won’t idle. The coil hitting could possibly be the source of the knocking. And maybe it’s running a little rich, so once you can get it running for any length of time try dialing in the carb needles a little leaner, high speed first then low speed. Can’t get it perfect in the bucket but it might help it idle a little better and smoke less.

-

This reply was modified 2 years, 8 months ago by

Steve D.

Steve D.

August 23, 2022 at 9:50 am #264771Thanks for the reply. I think the excess fuel check valve purge may be where I look next. I’ve attached links of the motor running in a barrel. The points have checked spot-on at 0.020″. Really three symptoms here.

1. Motor does not idle well

2. Motor smokes excessively. Oil mixture is the recommended 16:1. The smoking is new.

3. Seems to be some faint knock.

Thanks for all the advice.

Buster

OK, watched both videos. I realize that audio can be deceiving, but I don’t think this engine is running on both cylinders. Try pulling the plug wires one at a time while the engine is running, (please use insulated plastic pliers and keep yourself from getting wet so you don’t get shocked). The engine should stall when either plug wire is pulled. If pulling one of the plug wires doesn’t seem to change running RPM, then that cylinder isn’t operating for some reason. Could be a lack of spark, could be a compression/crankcase sealing issue, or perhaps water intrusion into the combustion chamber.

I don’t know what the loud knocking noise is all about, again the audio quality could be confusing this issue. I did notice that the tiller throttle control seemed to jump towards stop while you were pulling the recoil slowly, which makes me think something is dragging on the flywheel magnets.

Again, lets stick to basic/quick inspections/checks here before jumping in too deep.

August 24, 2022 at 12:38 pm #264878Check your coils one or both is too close to flywheel and knocking you throttle out of position. may be the sound you are hearing. While you are in there clean and re-gap the points. That where I would start.

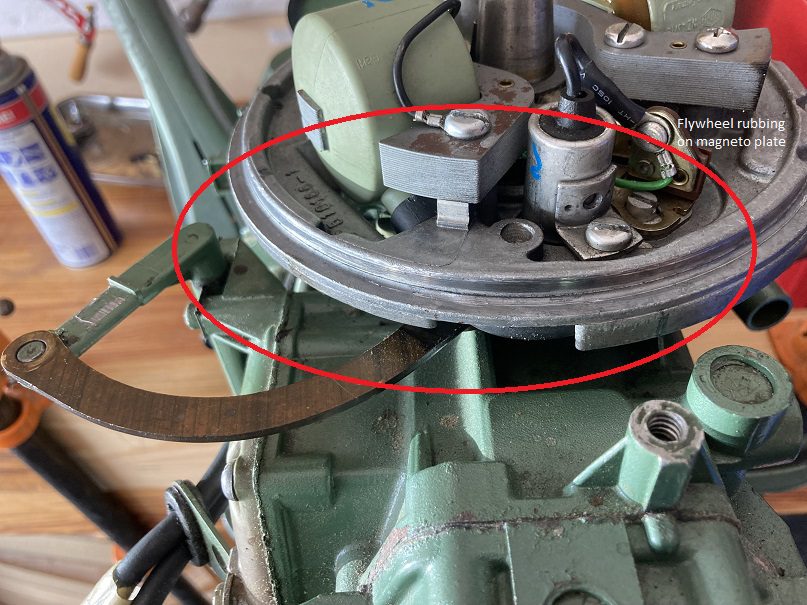

August 28, 2022 at 11:48 am #265099Pulled the flywheel today on the 5 and a half. The flywheel is scuffing on the magneto plate. I’ve attached a couple of photos showing the problem. When you pull the starter rope, you can see the flywheel torque on the mag plate in a certain arc of the rotation. With the wheel off, the scuffing is more clear. With my calibrated fingers, I figure there’s one to two thousandths lateral play in the mag plate. Any thoughts on how to remedy this? I wondered if the mag plate is not seated far enough on the taper.

Any advice helpful.

August 28, 2022 at 12:51 pm #265106excessive crankshaft play? also the back coil in picture looks black on side

August 30, 2022 at 8:11 am #265273OK, so the bottom of the crank is rubbing on the mag plate? You mention lateral movement in the mag plate, but how about up and down movement? I don’t know what could cause this issue unless the mag plate mount/support is improperly installed. Someone may have overtorqued the flywheel (with an impact gun) forcing the flywheel down and ruining the taper fit. Like others have said, looks like the other coil may be rubbing, do you have the correct coil alignment tool?

Did you figure out if the engine was running on two cylinders before you pulled the flywheel off again. Perhaps the knocking noise is being caused by the flywheel hitting the mag plate/coil, but you sure want to figure that out. I would check the rods for slop also, this can be done without pulling the powerhead apart.

-

This reply was modified 2 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.