Home › Forum › Ask A Member › Johnson CD-14 Frozen Pinion Gear-Shock Absorber

- This topic has 44 replies, 11 voices, and was last updated 5 years, 4 months ago by

fleetwin.

-

AuthorPosts

-

January 7, 2020 at 8:43 pm #191217

Thank you Labrador-guy. I already pulled the power head, drive shaft and pump housing. So I’m looking at the top of the shock absorber, which is still soaking in Evapo-Rust. If you have any advice on how to get the pinion gear off the bottom of the shock absorber, then maybe I could drive the shock absorber out from underneath with a wood dowel. Any advice much appreciated.

January 7, 2020 at 9:13 pm #191219James the pinion gear pulls straight out, once the gears are out of the way. Try a couple screw drivers on each side. The shock absorber should tap out with a punch. Sounds like the rust is making things move harder than they should. Usually these parts fall right out.

dale

January 7, 2020 at 9:36 pm #191221Thanks Dale. Was just working on it and I got it to turn! Big screwdriver down the middle of the shock absorber with a wrench on it. Its turning pretty well now, but I can’t get either the pinion gear or the shock absorber to pull out. So back in the evapo rust to soak for another day. At least I now know I have a salvageable lower unit, so I’ll order all the gaskets, impeller etc.

Thanks again.

Jim

January 7, 2020 at 11:28 pm #191230patience brings joy… let it soak 🙂 5.5 cd is a great little kicker and back-up ….. purrs all day

I sold one I refurbished & converted to pump to a fellow next door to my cottage

he still talks to me 🙂 and runs that 5.5 on his fishing trips

Joining AOMCI has priviledges 🙂

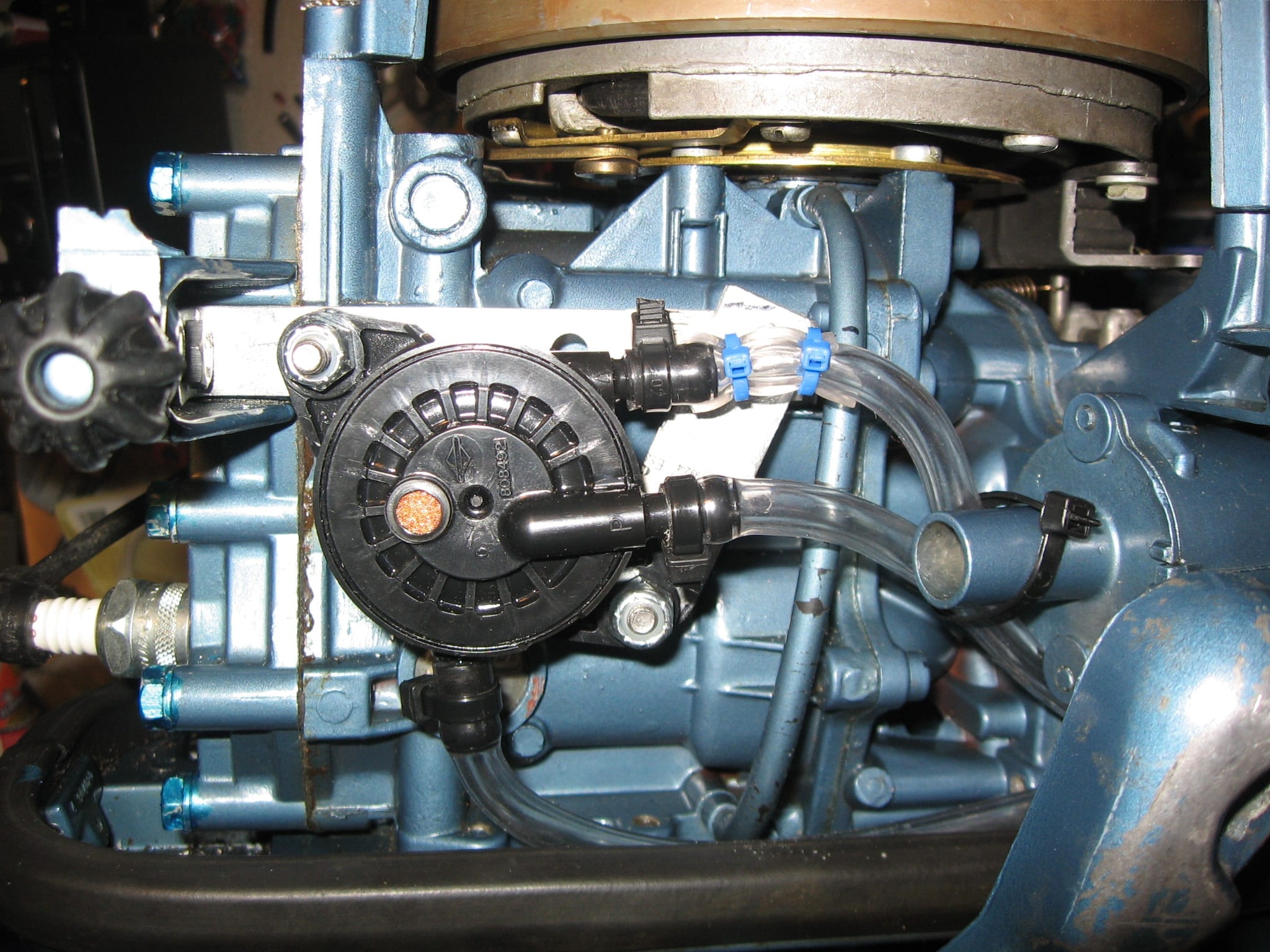

January 7, 2020 at 11:37 pm #191233see pic with a round Briggs pump mounted on the back cross bar.

Joining AOMCI has priviledges 🙂

-

This reply was modified 5 years, 6 months ago by

Mumbles.

Mumbles.

January 8, 2020 at 8:12 am #191250That’s a nice-looking pump installation.

January 8, 2020 at 12:05 pm #191259Thanks Dale. Was just working on it and I got it to turn! Big screwdriver down the middle of the shock absorber with a wrench on it. Its turning pretty well now, but I can’t get either the pinion gear or the shock absorber to pull out. So back in the evapo rust to soak for another day. At least I now know I have a salvageable lower unit, so I’ll order all the gaskets, impeller etc.

Thanks again.

Jim

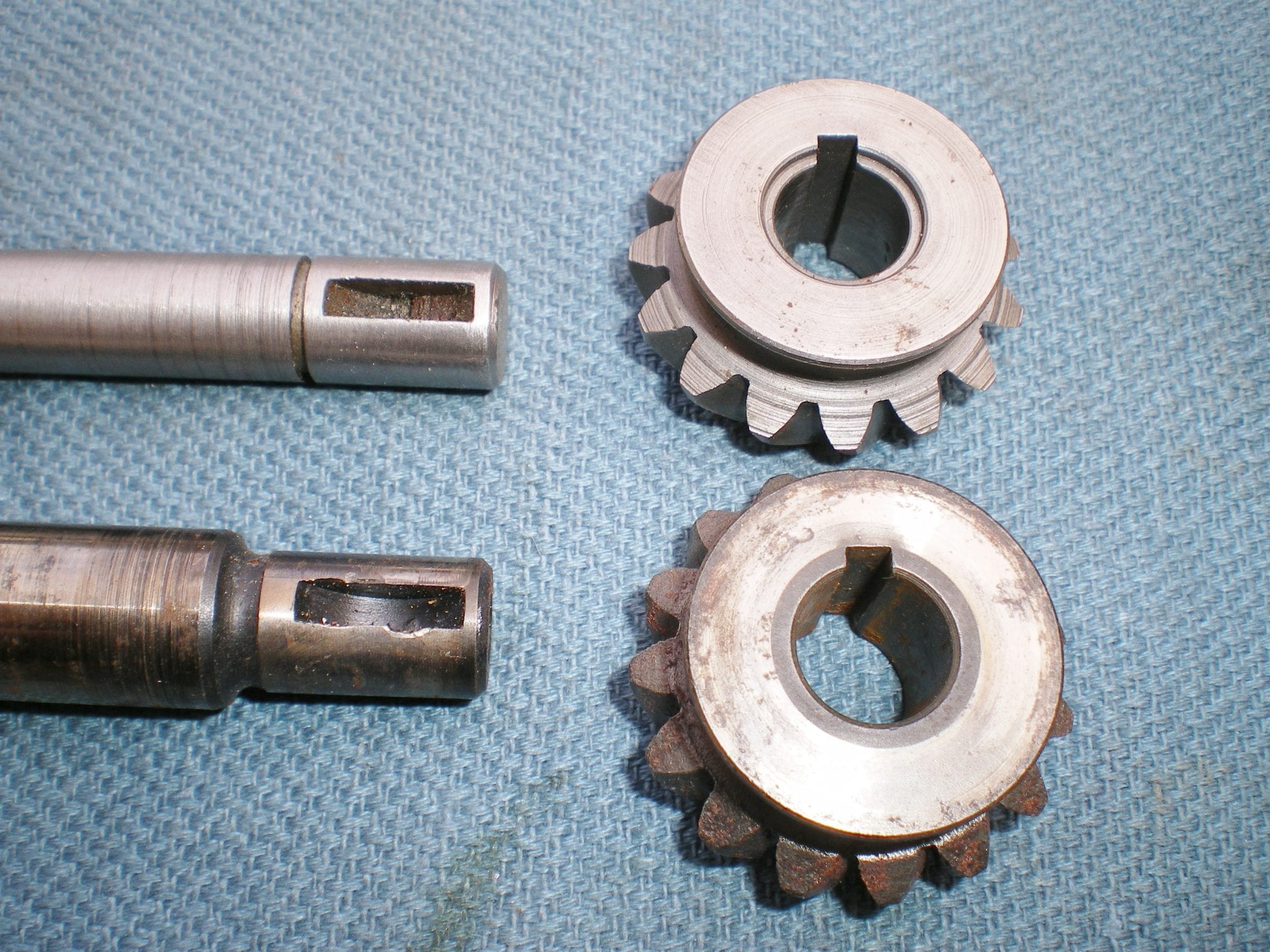

As previously stated, turn the gearcase upside down and drive the shaft out of the pinion gear using a large punch or small socket while trying not to lose the small Woodruff key which drives the pinion. If water was in the gearcase, these parts are probably rusted together so a big hammer and hitting it like you mean it should get these parts moving. A press will do it for sure.

Your pinion gear should be similar to the lower one in this photo.

January 8, 2020 at 8:58 pm #191303Success!! Screwdrivers didn’t work, but punch got it out. Not as rusty as I thought. I guess running it dry of oil overheated it and the heat caused everything to seize up. Will soak all parts for another day and start cleaning up and order gaskets etc. Drive shaft and shift rod bearings look ok. I’d rather not replace them unless one of you experts insists otherwise. Once this one is back running I have similar vintage Johnson 10, Evinrude 15, E 18, E 3 and an old old Johnson 1.5, all in need of various repairs. Should keep me busy for a few years!

Thanks again.Jim

January 9, 2020 at 12:05 am #191326January 11, 2020 at 6:28 am #191583IIRC the shock absorber can be seen in the middle of the pinion gear. If need be drive it out with a drift. A little heat may help. I just used some Aerokroil on a stuck motor and it did wonders. Expensive but worth it.

Heck even if you destroy the pinion and shock absorber, there are plenty around.

Good luck.

Greg

-

This reply was modified 5 years, 6 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.