Home › Forum › Ask A Member › Johnson FD 10 tight flywheel

- This topic has 10 replies, 8 voices, and was last updated 5 years, 8 months ago by

outbdnut2.

-

AuthorPosts

-

November 6, 2019 at 6:32 pm #186600

I was about to give up getting flywheel loose. I would tighten puller tight as I dared hold the weight off motor and wack with hammer with other hand. Then I got help and made a flywheel knocker. I had a wide nut screwed down 1/2 way and tightened hardened bolt to flywheel. My helper held the whole wight of motor holding flywheel. Them I griped a 3 lb hammer with both hands and after two mighty wacks it was loose.

-

This topic was modified 5 years, 8 months ago by

Mumbles.

Mumbles.

November 6, 2019 at 8:32 pm #186617What kind of puller were you using?

November 7, 2019 at 5:20 am #186622Funny, FDs don’t usually get that tight. I don’t think I ever had one that gave a fight against an OMC flywheel puller. (RDs, well, that’s another story….) If you tell me that knocker got it off when an OMC puller couldn’t, I will truly become a Believer.

Long live American manufacturing!

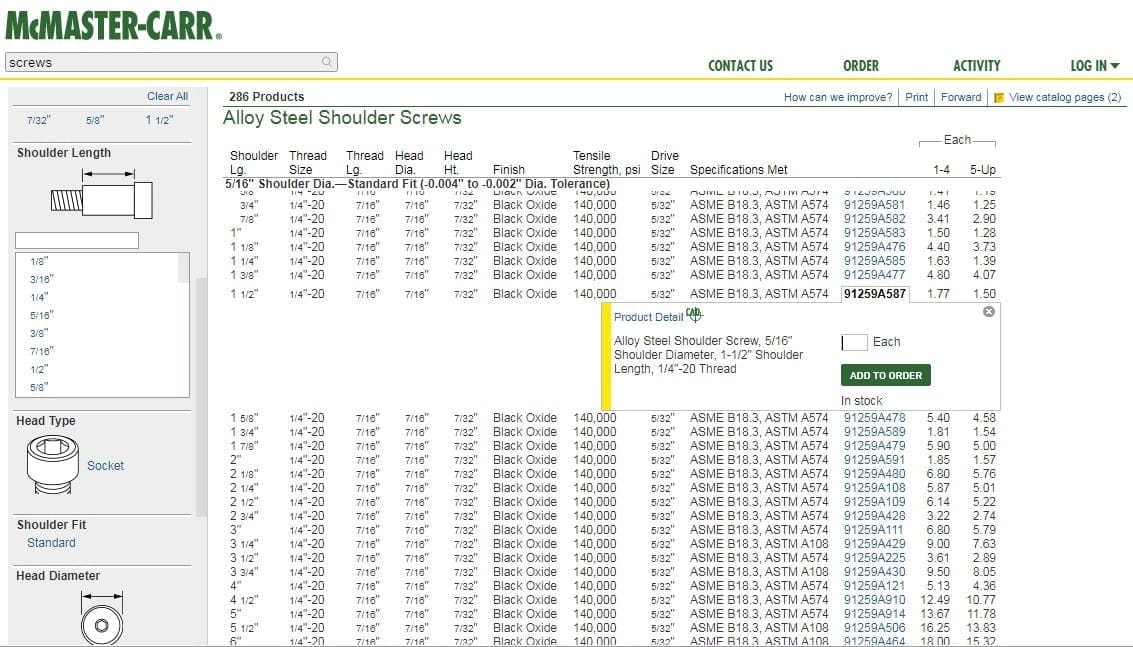

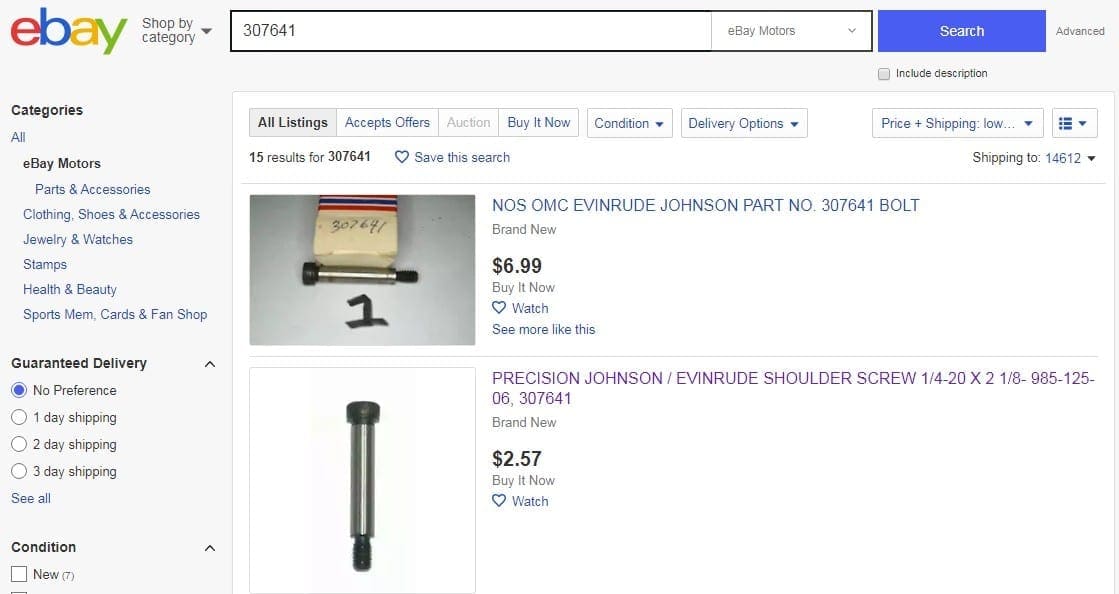

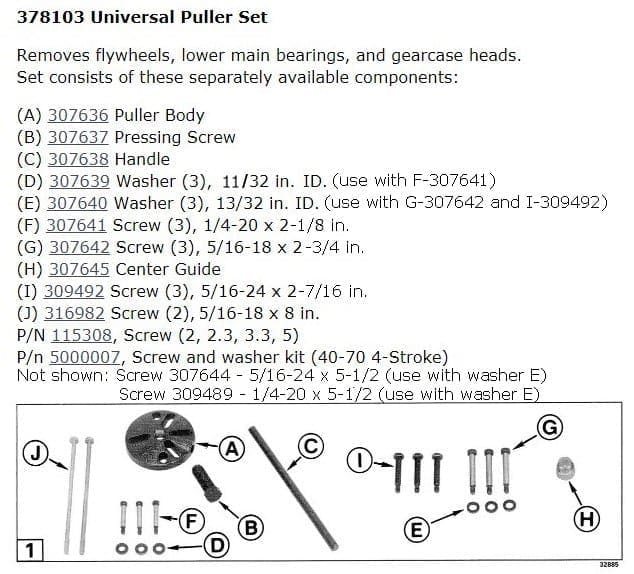

November 7, 2019 at 7:12 am #186631I have a heavy built Harmonic Balancer Puller. I can’t see any difference between OMC puller and HBP in the way they work. Both have a 5/8 fine thread bolt pulling 3 – 1/4 X 20 bolts. OMC cost $90 plus. How much torque can you apply before the 1/4 X 20 bolts break. I am pulling a 1 foot wrench as hard as I can and wedging long screw driver between 1/4 20 bolts. Maybe I could use a bigger wrench.

-

This reply was modified 5 years, 8 months ago by

mercuryman.

mercuryman.

-

This reply was modified 5 years, 8 months ago by

mercuryman.

mercuryman.

November 7, 2019 at 11:07 am #186658The OMC puller comes with shoulder bolts that align the puller with the flywheel. If you use non shoulder bolts you can get the puller cocked, even just a little, and the tighter you make it the the more it wedges the flywheel. You could get some shoulder bolts for the puller you already have and get the same effect.

Whacking while lifting works too.November 7, 2019 at 5:36 pm #186679soaking the crankshaft with some release agent a few days should help….. oddly enough the clear silicone spray used in snowblowers to stop snow and ice sticking seems to have great capillary properties. I just did my flywheel on a MQ11 and it came off with a bang !

Joining AOMCI has priviledges 🙂

November 7, 2019 at 6:49 pm #186692Thanks for info now I understand to difference, I am going to try some shoulder bolts.

November 8, 2019 at 7:54 am #186718The OMC puller definitely makes a difference. I also use one of those electric impact guns instead of just a wrench/breaker bar on the puller screw….

November 8, 2019 at 3:11 pm #186736November 10, 2019 at 2:49 pm #186887Yes to the shoulder bolts, i also recently purchased the OMC puller and the harmonic balancer puller that i used for many years now sits idle.

2Fast4Me

-

This topic was modified 5 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.