Home › Forum › Ask A Member › Johnson JW-12 rebuild questions

- This topic has 13 replies, 6 voices, and was last updated 6 months, 3 weeks ago by

Tacitus043.

-

AuthorPosts

-

June 28, 2024 at 1:50 pm #288704

Hi Guys,

I am in the process of rebuilding a Johnson JW-12 I received from a friend. The motor has sat for at least 30 years and is pretty full of crud. That being said many of the hard parts seem to clean up fine, and I am at the point where I need to start thinking about the new parts I need for reassembly. Certain parts like the water pump impeller, ignition system, and some gaskets seem readily available through a google search, however other parts I need like the piston rings, bearing clearance specs, and various other gaskets seem more elusive. I figured I would ask you guys to see your thoughts.

-Powerhead / rotating assembly:

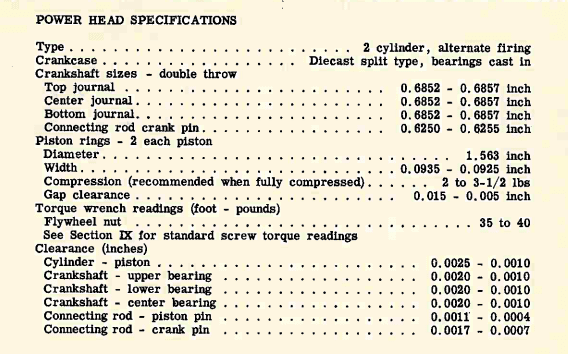

Does anyone know a place I could specs on the main and rod journals, as well as clearance specs? At first I assumed new bronze shells would just drop in, but it almost seems like they are crimped into the case, and something tells me obtaining replacement ones will be ready hard. My plan now is to just polish the crank and run it unless something is grossly out of spec. My biggest worry is that the old bronze bearings won’t seal the crankcase and the engine will have trouble breathing.

The old rings were completely stuck into the ring lands and fought me pretty hard while I was trying to unstick them. The last ring I took out ended up breaking. Does anyone know a good place I can find rings for this little engine, or a modern part number that would work? I found an old part number but it doesn’t seem to cross reference to anything for sale online.

-Carburetor

The carb was really nasty but cleaned up for the most part. My biggest issue is that the high speed needle broke off in the bowl. I was able to drill it out; my plan was to tap it and buy a new needle. I assumed the needle threads were 1/4-28, but when I took a closer look they look much finer. Does anyone know the high speed needle thread size? Worst case I may just need a whole new bowl and needle.

-Lower Unit / Seals

Best place to find seals for the drivetrain? I don’t want this thing leaking gear oil out into the water.

I noticed there was remnants of an o-ring on the shaft that engages the crankshaft snout. Anyone have specs on that o-ring?

Sorry if that was long winded. I’m really looking forward to getting this little engine back on the water. My friends think I’m crazy for spending time to fix this thing, but so far I’ve had a ton of fun working on it Thanks for taking the time to read this post and I appreciate any help!

June 28, 2024 at 2:23 pm #288709Well I can start with a Parts manual. Attached PDF

With part numbers it’s interesting how many things can be found on e-bay and similar; including the Classifieds here on this site. Prices add up fast though; might make sense to consider getting a parts motor. Lots of the same parts over the years of the JW’s production.

June 28, 2024 at 3:59 pm #288713I do have those parts on hand. Run a parts list by part number from the parts book and send to me. I will give you a cost estimate.

Ed Elliott, eddelliott@cox.net

1 user thanked author for this post.

June 28, 2024 at 5:15 pm #288716That little o-ring on the drive shaft is critical. It keeps water out of the drive shaft splines Leave it out and the splines will rust & wear out. Result: it goes nowhere.

1 user thanked author for this post.

June 28, 2024 at 5:51 pm #2887181 user thanked author for this post.

June 28, 2024 at 7:04 pm #288720Needle valves are 1/4-40 thread

1 user thanked author for this post.

June 28, 2024 at 10:14 pm #288735The one thing I notice are all the drag marks/scrapes inside the #1 crankcase, almost looks as though this thing may have tossed a rod in the past. The pistons seem newer because they only have two rings… Someone may have replaced the crank, or perhaps the “polished” some of the imperfections off if in fact the engine threw a rod. So, I would measure those crank pins very carefully along with the big rod ends.

Frank offers excellent advice by drawing attention to the crankshaft and driveshaft splines. Clean them up and examine the crank/driveshaft splines very closely. The last thing you want is to reassemble this powerhead only to discover the splines have spun/rusted away when you start the engine and the prop doesn’t spin!

1 user thanked author for this post.

June 28, 2024 at 10:15 pm #288736PS:

The bronze bushings in the crankcase look “OK”, not sure if they publish any sort of spec for clearance/sideplay other than the dimensions of the crank itself…

1 user thanked author for this post.

June 29, 2024 at 9:19 am #288738Thanks for the replies!

Ed, email sent.

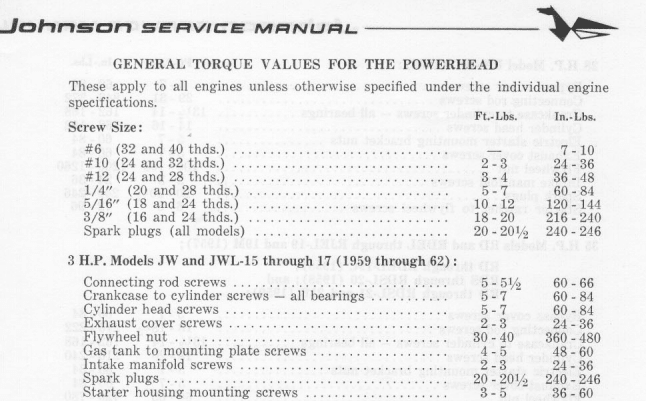

I had to work today but I was able to to a cursory mic out of the crank and rod journals this morning. So far everything seems to be on the high end of the specs that Frank posted.

The leading edges of the male splined shaft that engages the crankshaft do appear to have wear, however, I can slide on the crankshaft and nothing seems to skip or turn even with resistance.

Any recommendations on grit size for honing? I was planning on using a ball flex hone.

Also, any tips for break in? I’ve never run in a 2 stroke before. I didn’t know if you needed to change anything with the mix to get the rings to seat in better. Thanks!

June 29, 2024 at 11:12 am #288740The ball hone is a good choice, very fine grit just enough to break the glazed surface on the walls. oil mixture for that engine should be 16:1, use TCW3 outboard oil…

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.